Receiving device for bilaterally collecting electric spinning polymer fiber tubes

A receiving device and polymer technology, applied in fiber processing, pipes/pipe joints/fittings, hoses, etc., can solve the problems of wasting materials, limiting the receiving range of metal rods, thick in the middle of the pipe wall, and thin at both ends

Active Publication Date: 2009-09-16

领博生物科技(杭州)有限公司

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

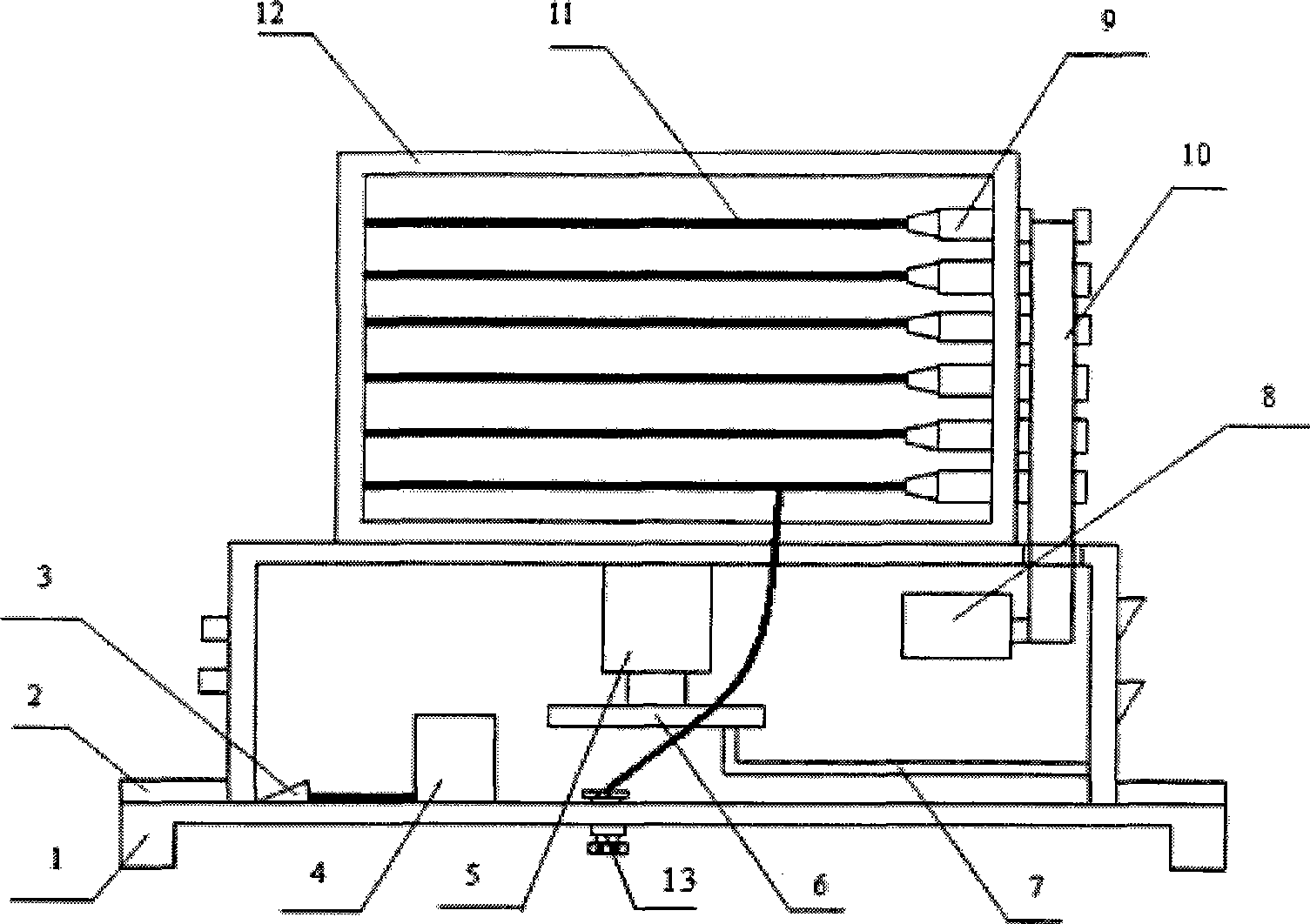

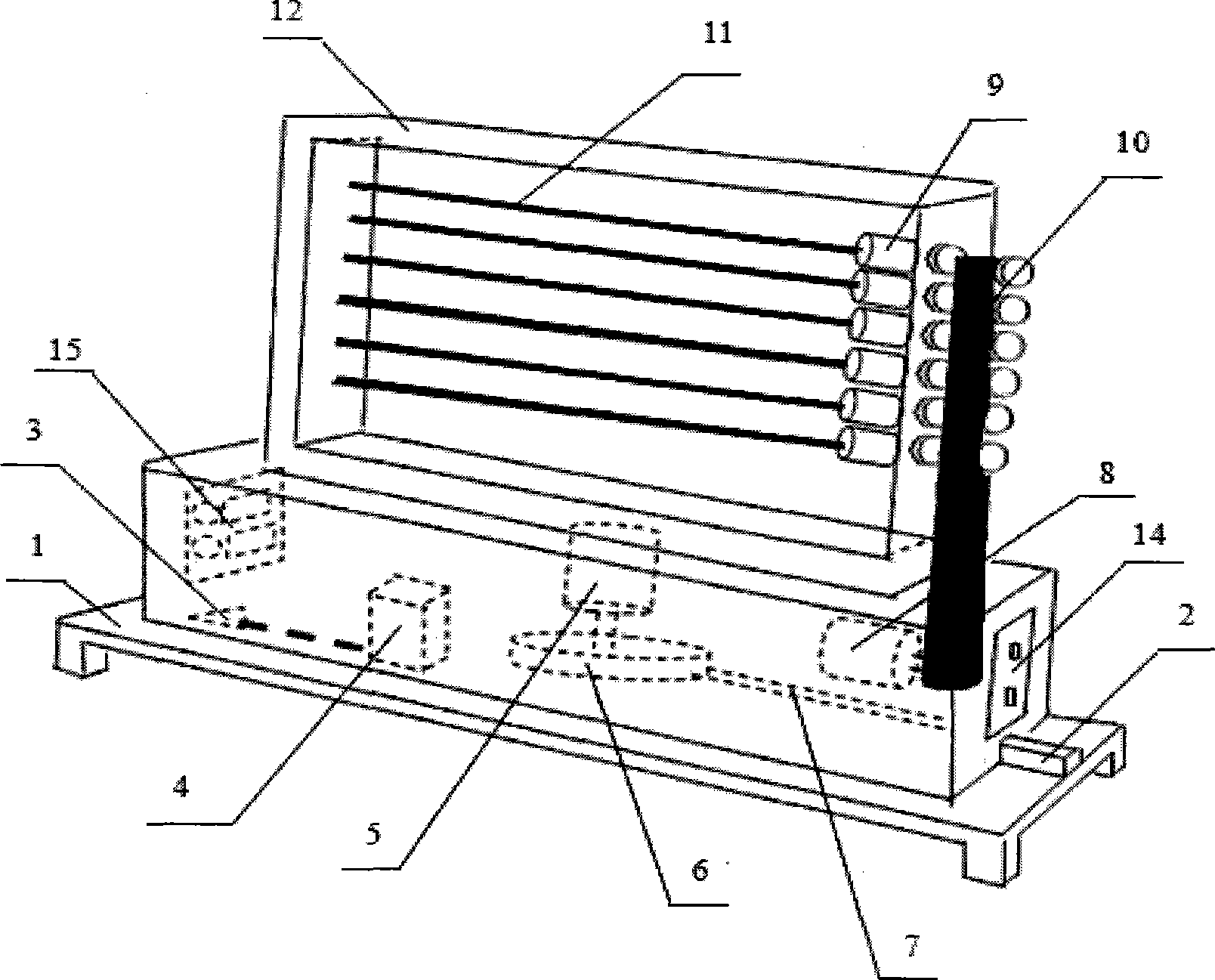

The defect of the existing device technology is: because the fiber ejection point is fixed, and the metal rod moves at a uniform speed in the horizontal direction, the obtained tube is in the shape of thin ends and thick middle; the fiber ejection point is located directly in front of the middle point of the track, so There are fewer fibers sprayed at both ends of the phase track, and the original device returns immediately when the metal rod moves to the two ends of the track, which cannot provide sufficient time to collect fibers, resulting in the phenomenon that the middle of the tube wall

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a receiving device for bilaterally collecting electric spinning polymer fiber tubes and aims at providing the device for preparing a porous fiber tubular material which is composed of two types of polymer fiber and has the even wall thickness on the radial direction and the axial direction. The bilateral receiving device comprises a receiving frame system which is independent of a host box body, a controllable regulation system for rotation speed of a metal rod, a rotating disc-connecting rod system which drives the metal rod to do the gradient non-uniform motion on the horizontal direction and a controllable pause system of the host box body arranged at two ends of a track. Wherein, the receiving frame system can realize the bilateral simultaneous collection of fiber; the controllable regulation system for the rotation speed of the metal rod can realize the adjustable speed of the received metal rod by over-regulation of the rotation speed of a speed control motor; the rotating disc-connecting rod system can realize the gradient non-uniform motion of a host on the horizontal direction; and the controllable pause system of the host box body arranged at two ends of the track can realize the controllable pause of the host box body at two ends of the track. The receiving device is applicable to preparing tissue engineering blood vessel stents and other porous fiber tubular materials.

Description

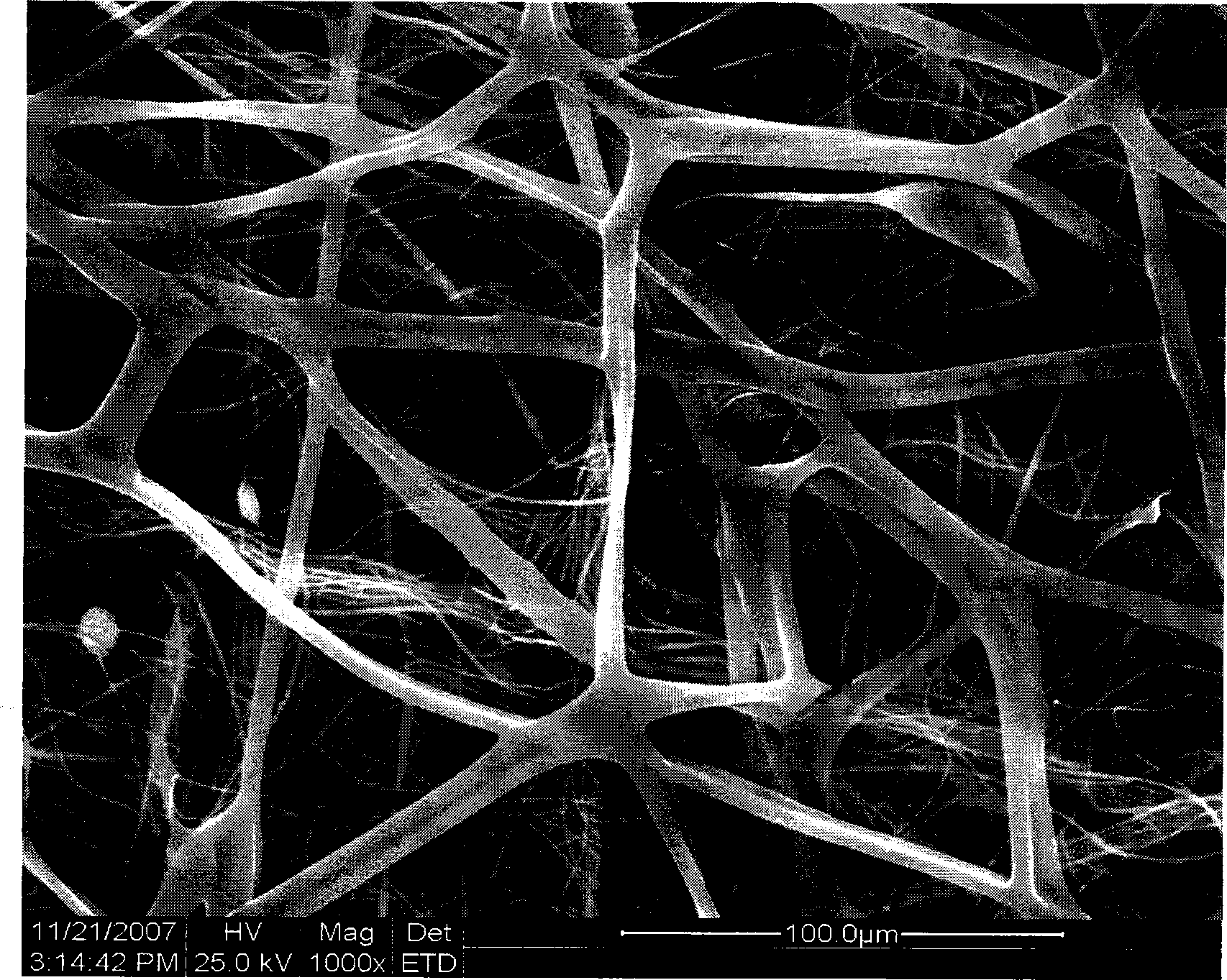

technical field [0001] The invention relates to a device for collecting electrospun polymer fiber tubes, in particular to a receiving device for collecting different electrospun polymer fiber tubes from both sides by receiving the rotation and translation of a metal rod. Background technique [0002] In the electrospinning process, the polymer solution at the capillary mouth is stretched into polymer fibers with diameters ranging from micrometers to nanometers under the action of tens of thousands of volts of high-voltage electrostatics, and sprayed to a zero-potential receiving device. The solvent evaporates quickly, and when the receiving device is a grounded metal rod, the fibers are deposited on its rotating surface and removed to obtain a tubular polymer material. Currently, it is possible to collect an electrospun polymer fiber into a tube from the receiving metal rod side. The existing device is equipped with parallel metal rods at the front end of the host box, whic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01D13/02D01D5/00F16L11/02

Inventor 孔德领魏迪王淑芳王存仁

Owner 领博生物科技(杭州)有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com