Method for rebuilding simply-supported beam bridge into semi-integral bridge abutment beam

A semi-integral, simply supported girder bridge technology, used in bridges, bridge materials, bridge maintenance, etc., can solve the problems of easy damage to the device, inconvenient maintenance and other problems, achieve simple construction, low investment, and reduce the total cost of bridge maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] (1) Measurement stakeout

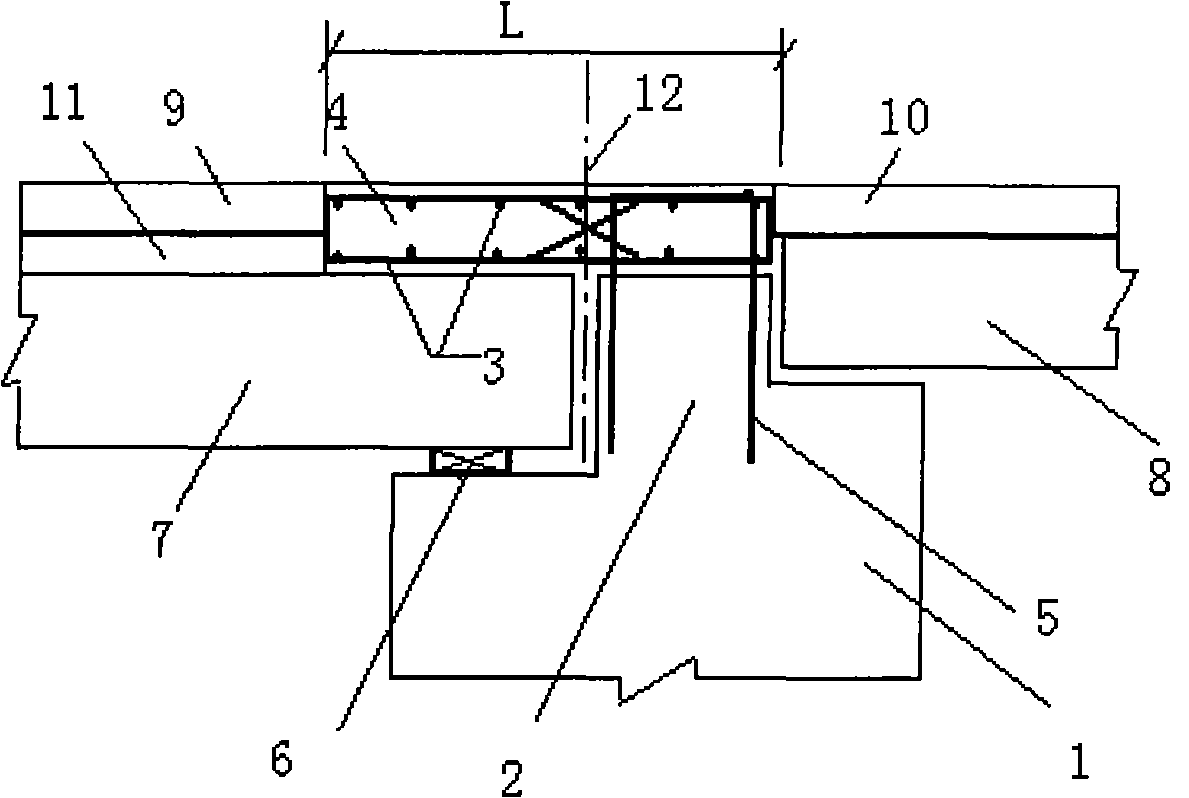

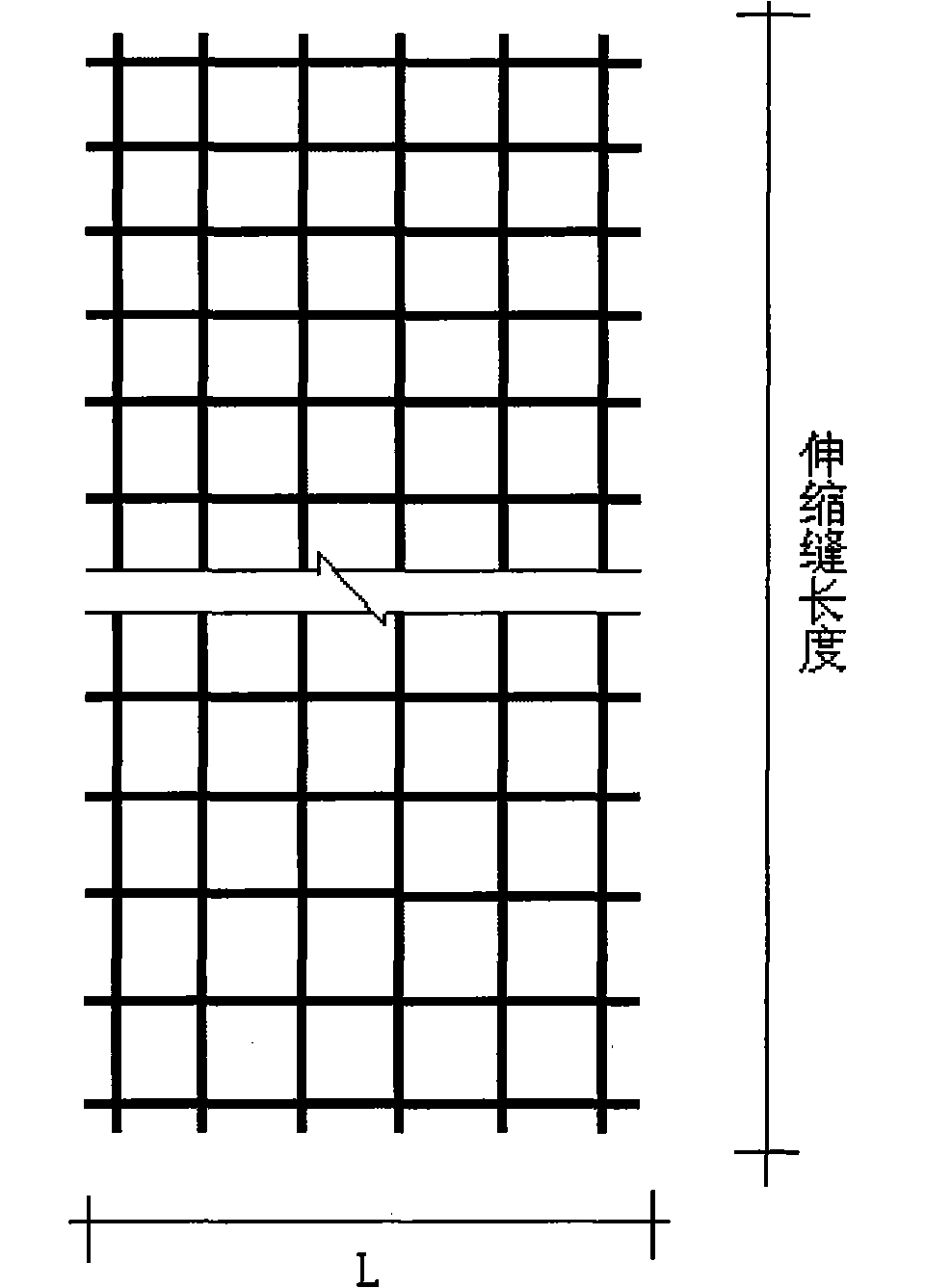

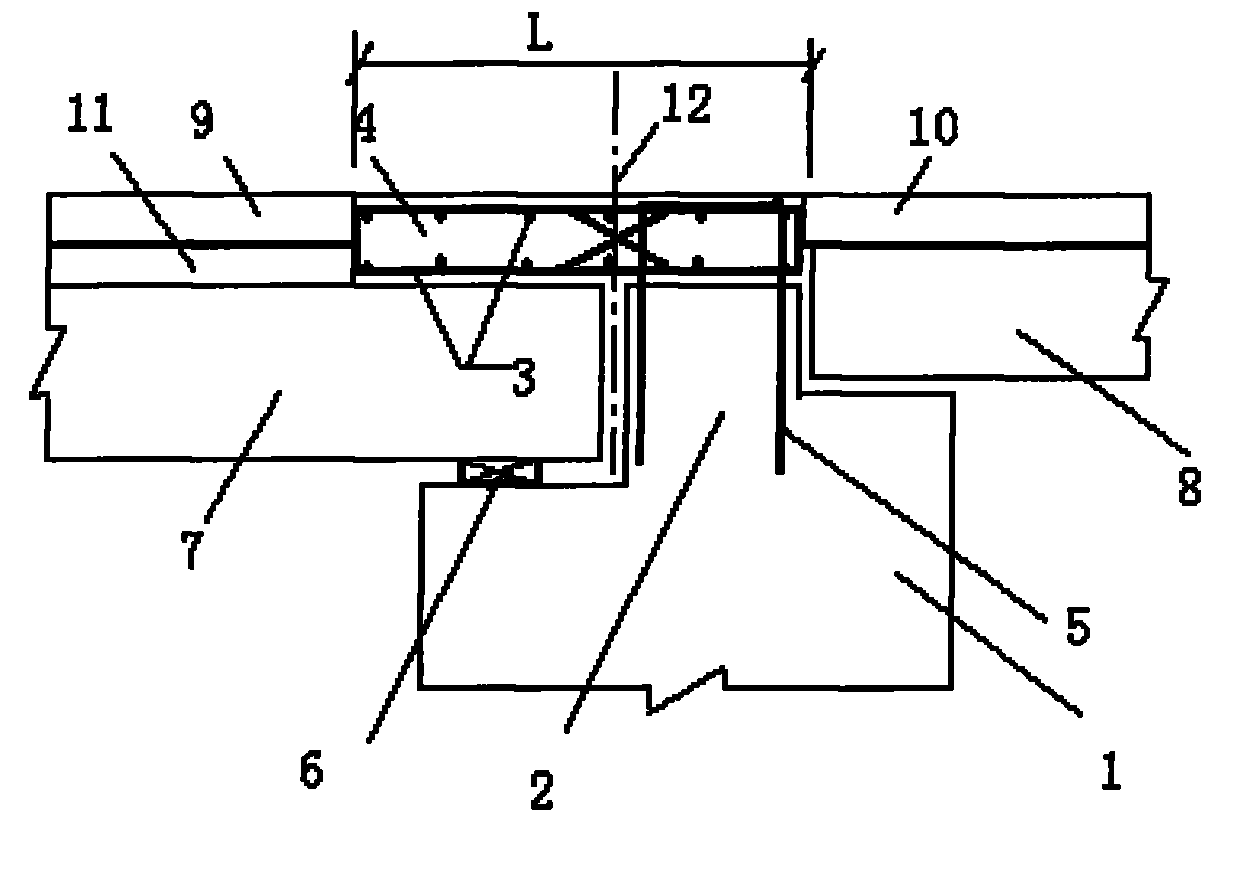

[0024] Seam to the center line of the expansion joint ( figure 1 The two sides of the longitudinal center line 12) shown in the figure show a straight line sample parallel to the expansion joint, one of which is located in the direction of the platform back 2 about one platform back width away from the expansion joint to the center line, and the other is located at the bridge The straight-line samples in the direction of surface 9 are about 50CM away from the center line of the expansion joint, and the distance between two parallel straight-line samples is figure 1 The L shown in, the L is about 80CM long.

[0025] (2) Slit slotting, chisel removal and cleaning

[0026] Along the above two linear cuts parallel to the direction of the expansion joints, the depth of the cuts is about 10CM (that is, the thickness of the asphalt concrete layer 9 on the bridge deck), and the original asphalt concrete between the two cuts is removed, and the origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com