Structure of lead wire protective tube

A wire protection and tube structure technology, applied in the directions of linear motion shafts, flexible shafts, shafts, etc., can solve problems such as increased production of machines and tools, wire movement blocked, brittle cracks, etc., to save costs and stabilize the protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

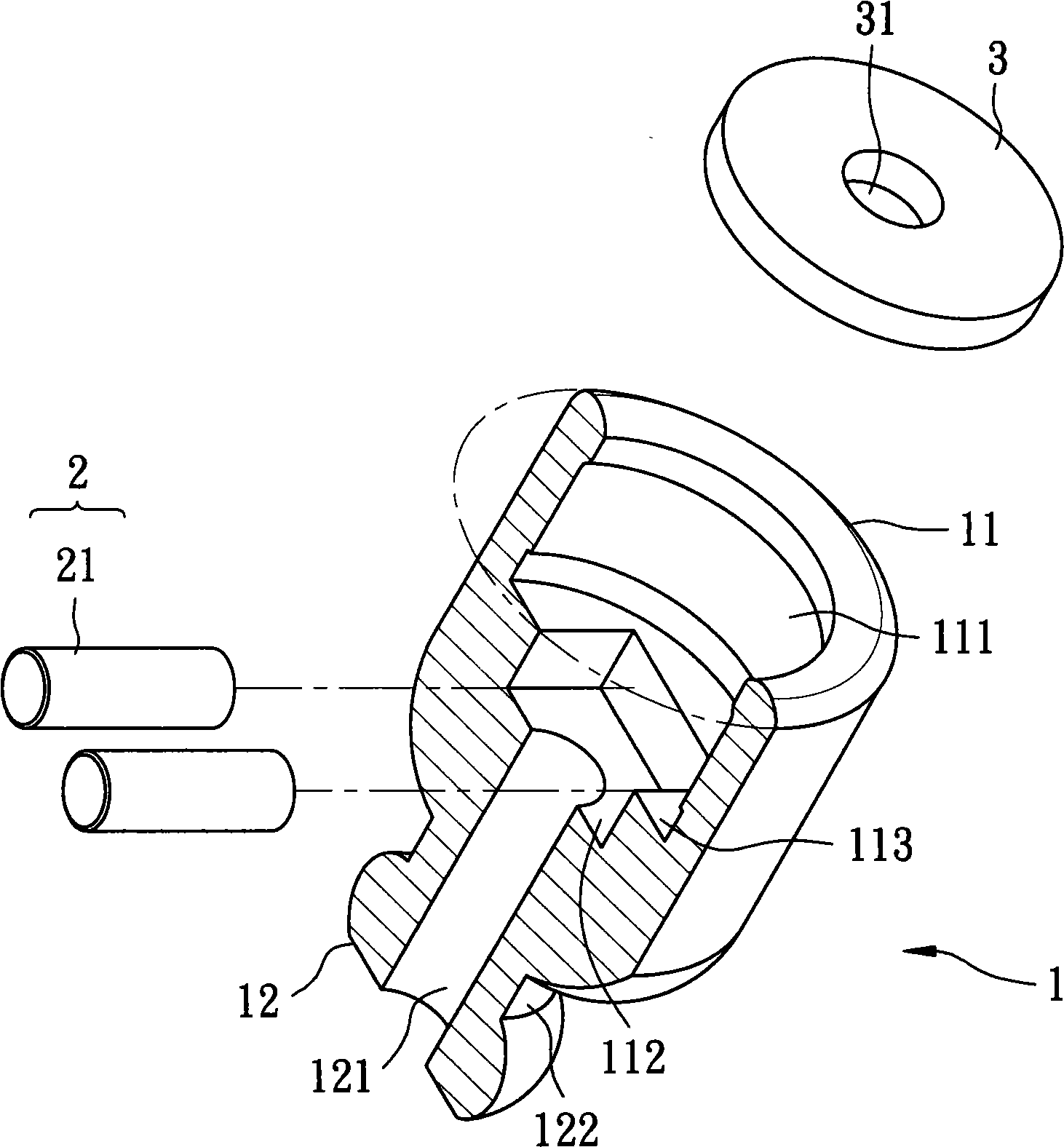

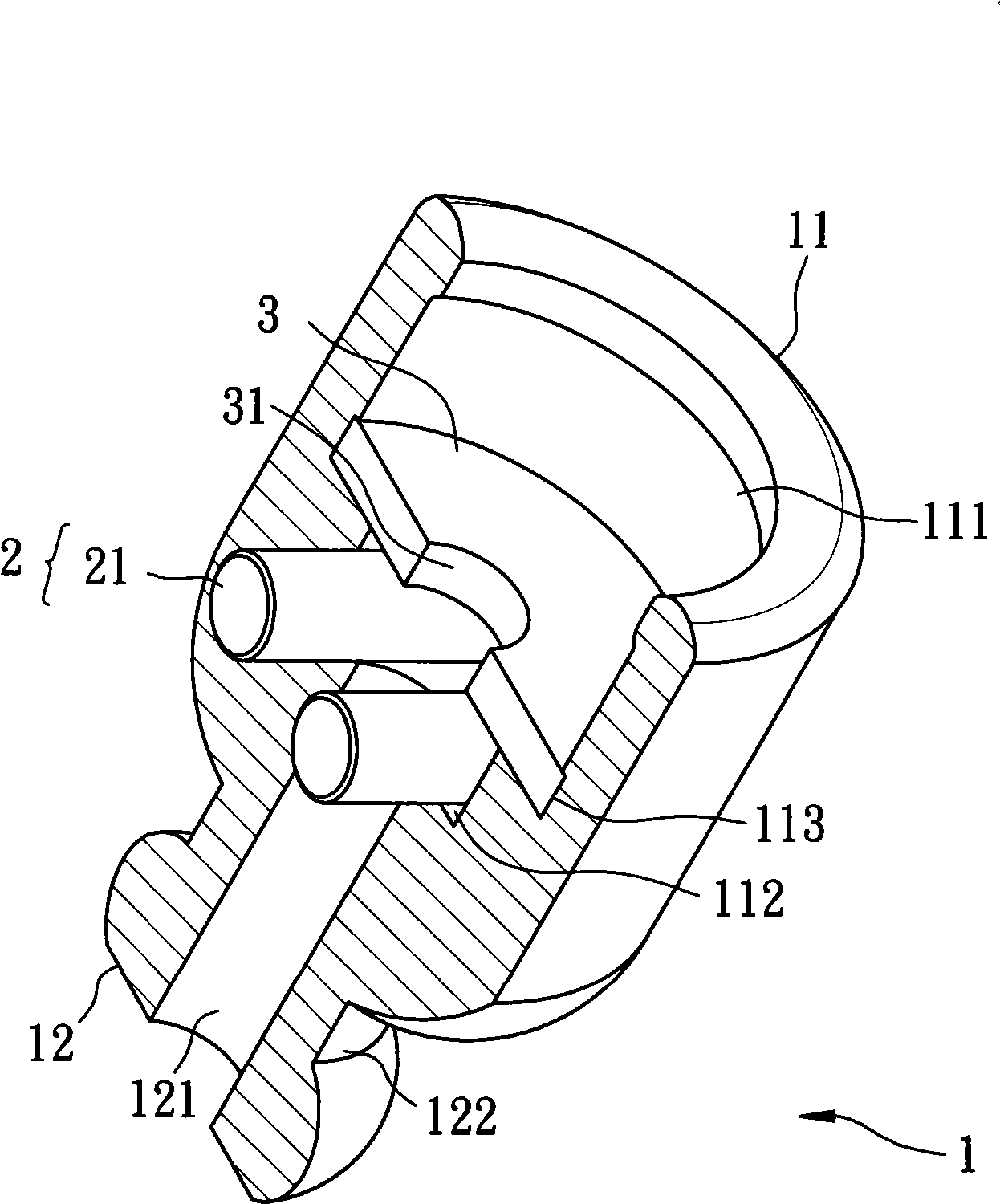

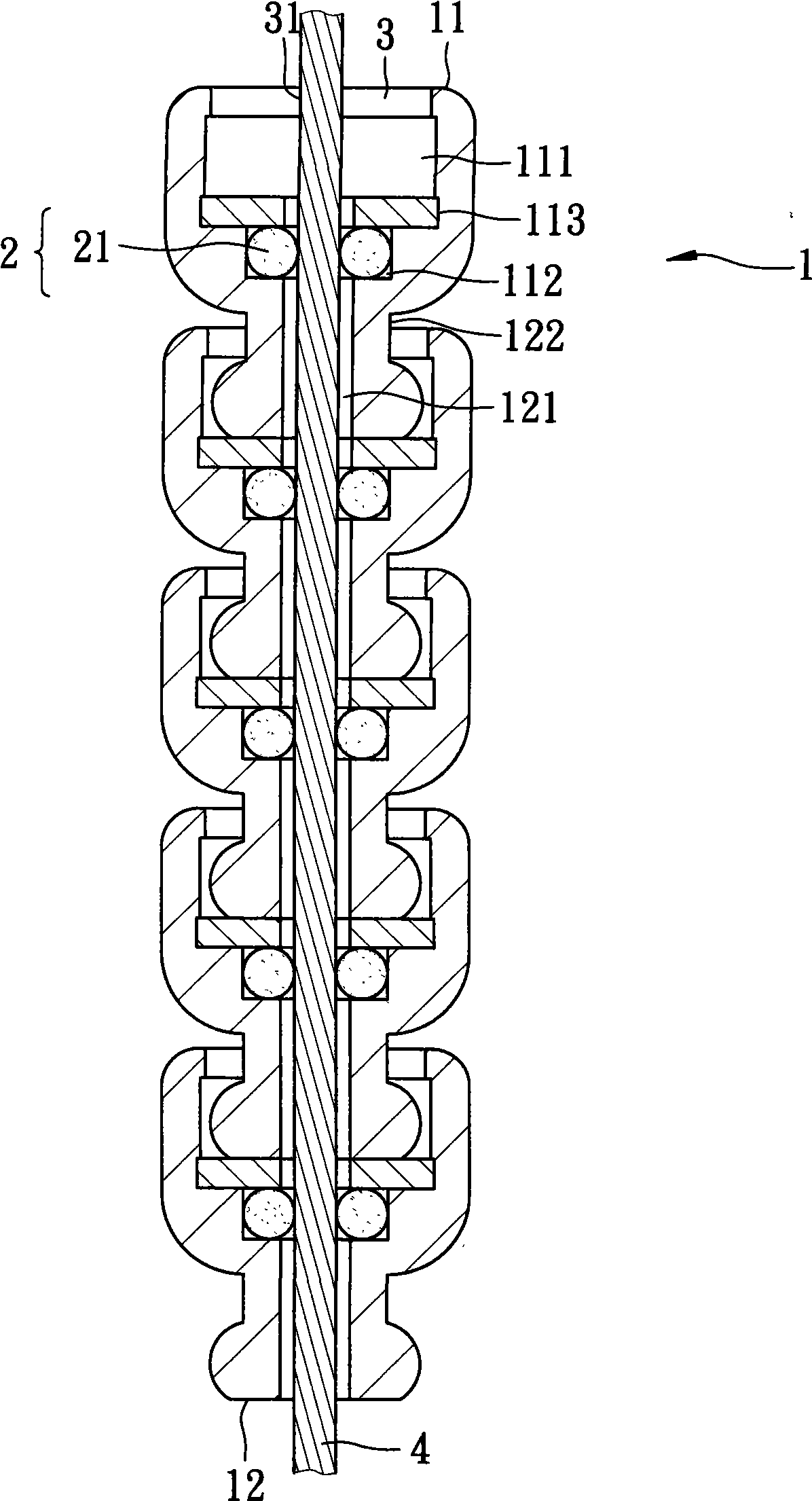

[0032] The present invention relates to a wire protection tube structure, please refer to Figure 1 to Figure 4 As shown in the first embodiment, it includes a shaft tube 1, the shaft tube 1 is provided with a first end 11 and a second end 12, wherein:

[0033] Such as figure 1 As shown, since the perspective view cannot show the structure installed inside the shaft tube 1, the part of the shaft tube 1 is shown in section, as shown in figure 2 shown;

[0034] The shape of the shaft tube 1 is generally columnar, the diameter of the first end 11 is larger than that of the second end 12, the shaft tube 1 is provided with a ring recess 122 adjacent to the second end 12, and the second end 12 The shape has a curved surface; the first end 11 of the shaft tube 1 is axially provided with a housing part 111, the diameter of the housing part 111 is slightly larger than or equal to the second end 12 of the shaft tube 1, and the inner bottom surface of the housing part 111 A slightly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com