Tubular flexible neon lamp

A neon light and flexible technology, which is applied to the damage prevention measures of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc. It can solve the problems of point light sources, products that cannot be cut, and light-emitting angles that cannot be reached. Cost-saving, uniform scattering, and the effect of eliminating the need for fixed brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

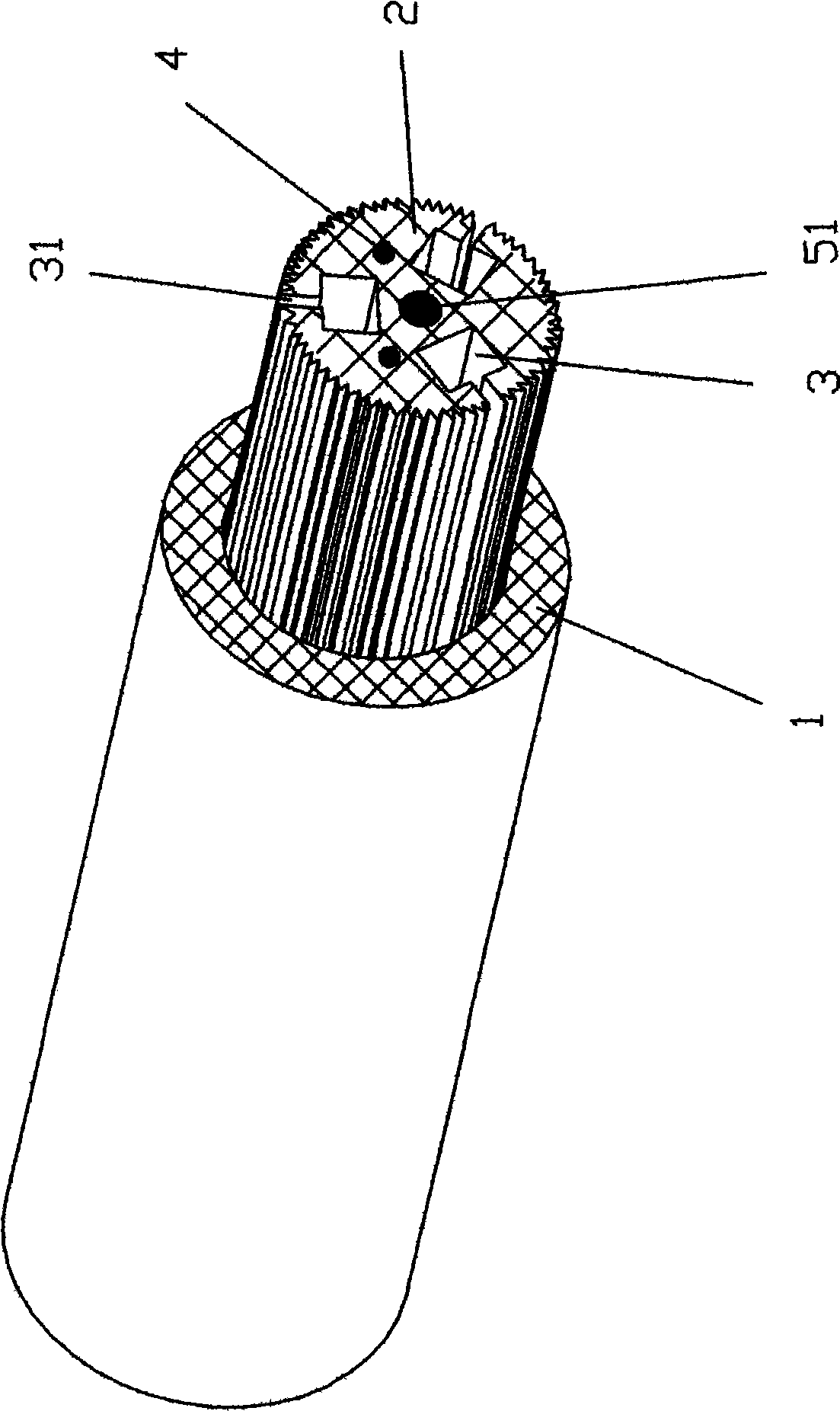

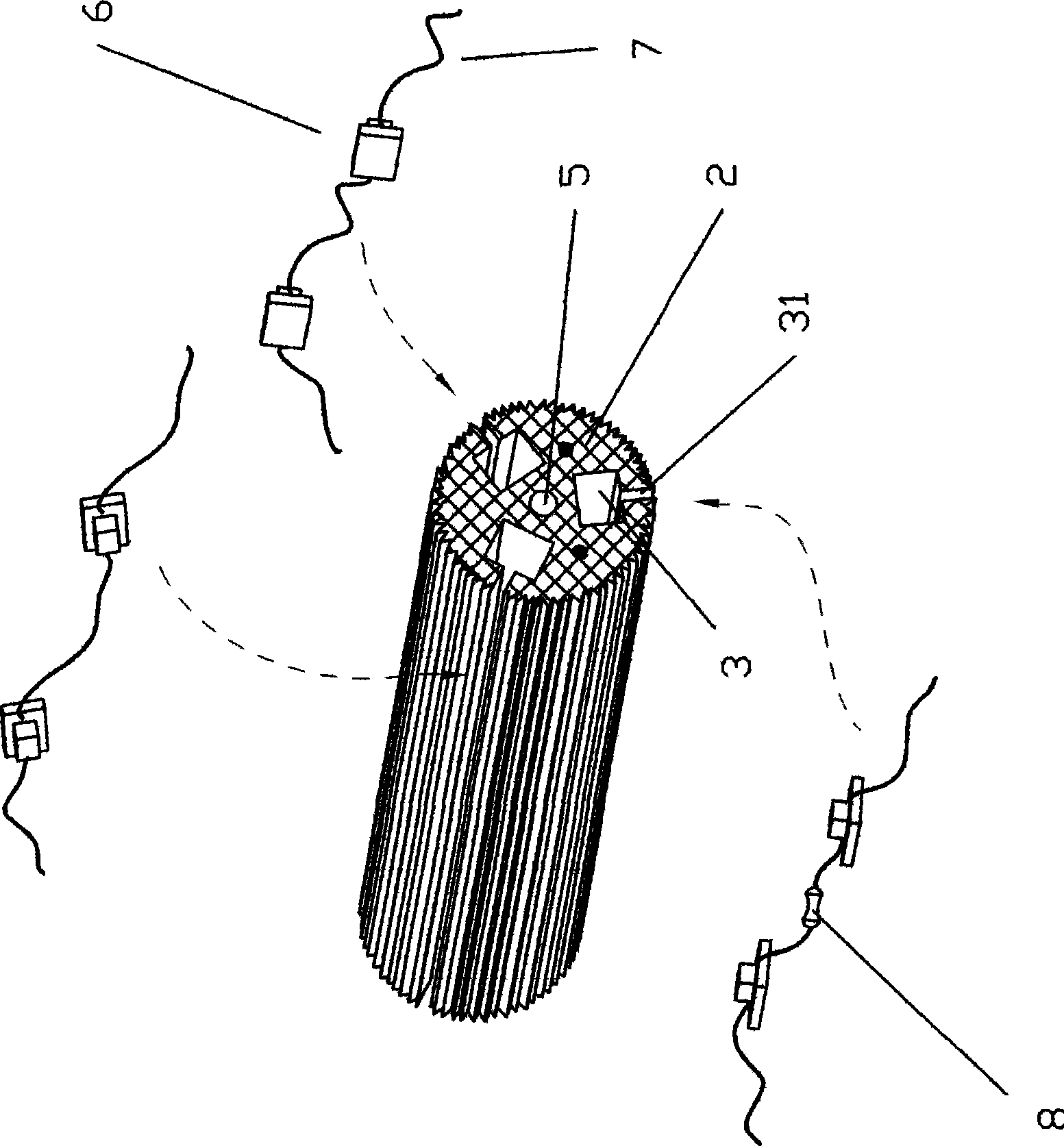

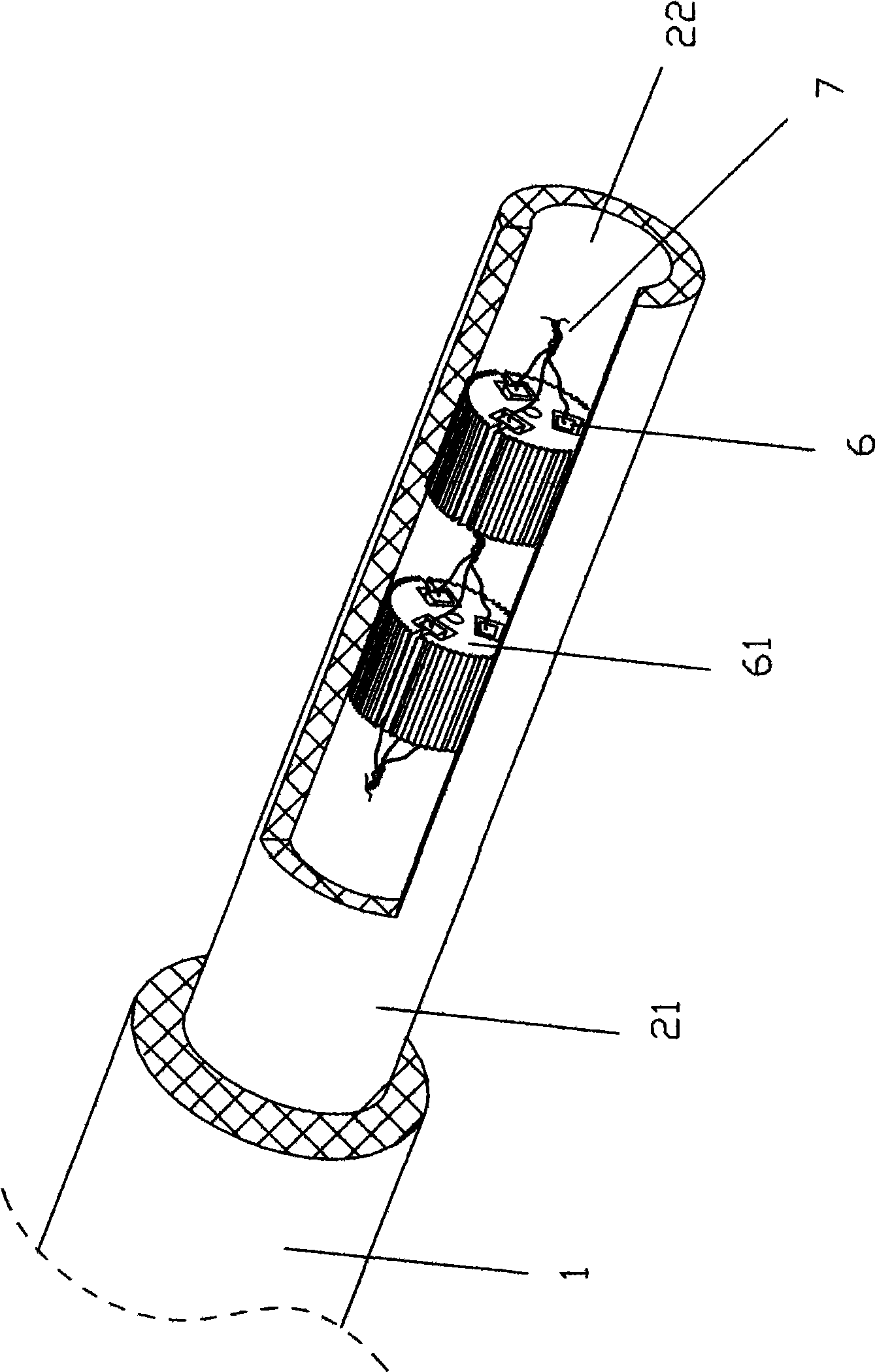

[0036] refer to Figure 1-2 . The present invention includes a flexible lamp body core wire 2, the flexible lamp body core wire is extruded and formed by flexible plastic, the lamp body core wire is a light-transmitting plastic strip, and its cross-sectional profile is circular or triangular, or it can be For other shapes, the material is transparent plastic material, or it can be milky white or colored plastic with light transmission but opaque. In order to produce better light scattering effect, several horizontal or vertical rib stripes can be set on the surface of the core wire. The core wire is provided with at least two wires 4 which can be electrically connected to the power supply along the longitudinal direction, and a number of slots 3 are arranged in the core wire along the longitudinal direction. There is at least a cut 31 between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com