Single flow direction connector module

A connector module and single-flow technology, which is applied in the field of single-flow connector modules, can solve the problems of difficult welding, difficult to determine the length of the connector, and difficult operation, and achieve the effects of shortening the production cycle, reducing the amount of processing, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The unidirectional connector module proposed by the present invention is described in detail as follows in combination with the embodiments and accompanying drawings:

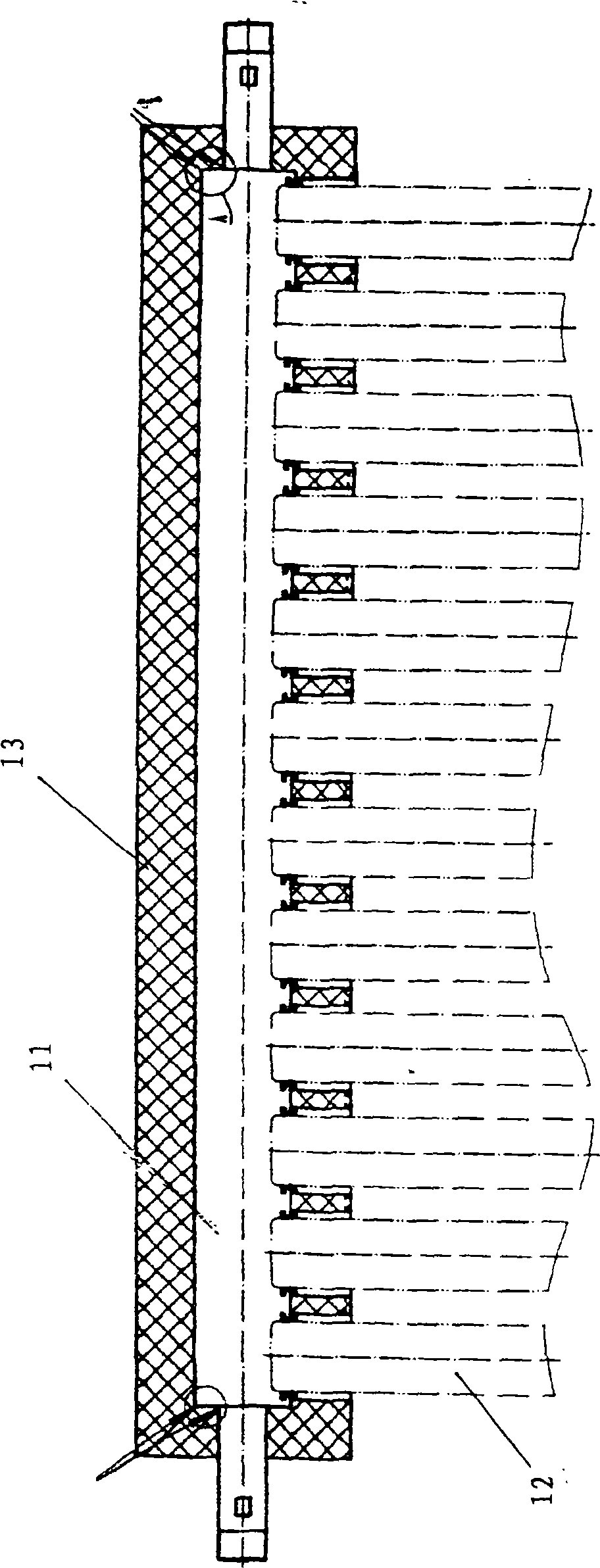

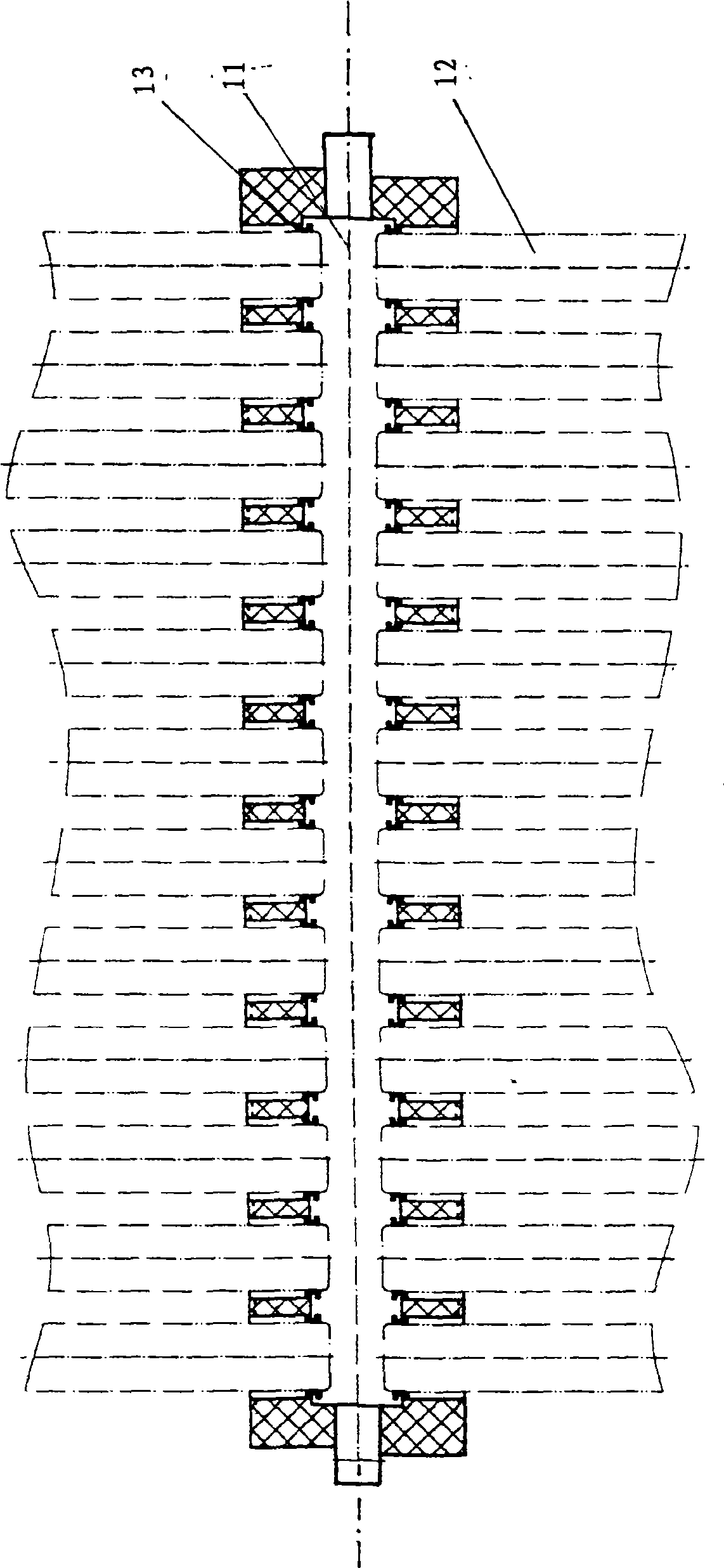

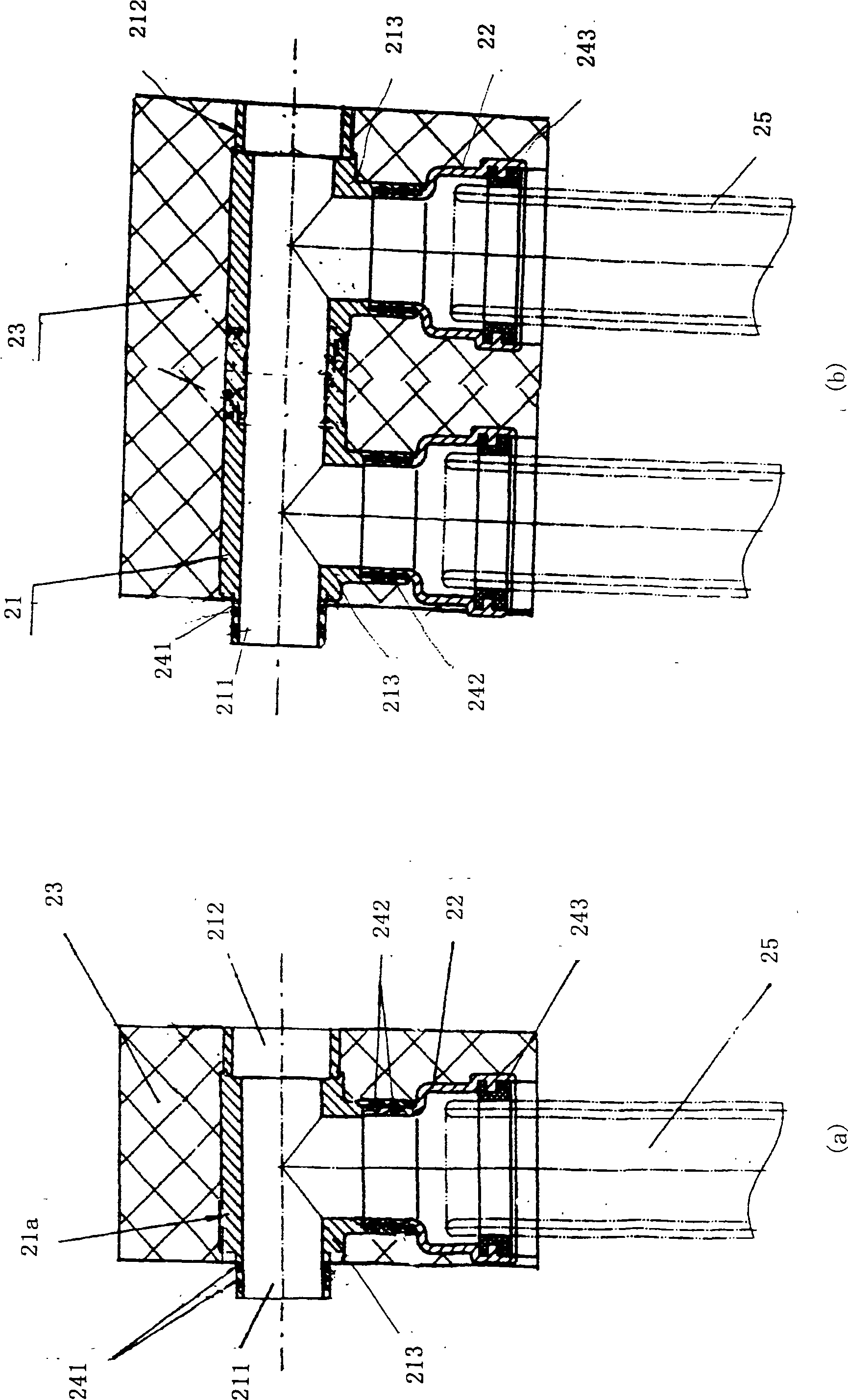

[0018] The structure of Embodiment 1 of the unidirectional connector module of the present invention is as follows figure 2 shown. In this embodiment 1, modules with two structures are designed. The first structure is a connector module that can be combined with a heat collecting tube on one side. Its structure is as follows figure 2 As shown in (a), it is composed of a three-way pipe 21a, a heat collecting pipe joint 22, an insulation body 23 and a sealing ring. The three-way pipe has a left male port 211 and a right female port 212, (the female port and the male port can be replaced exchange) and the lower interface 213 connected to the joint of the heat collecting pipe, the tee pipe 21 is arranged in the heat insulating body 23, the outer wall of the male port is provided with a sealing ring groove, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com