Control device and control method for cooling frames of hot milling roll

A technology of cooling control and cooling device, which is applied in the direction of temperature control without auxiliary power supply, temperature control, temperature control using electric mode, etc. It can solve the problems of increasing the frequency of cooling water volume increase and decrease, complex control structure, and reduced temperature accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

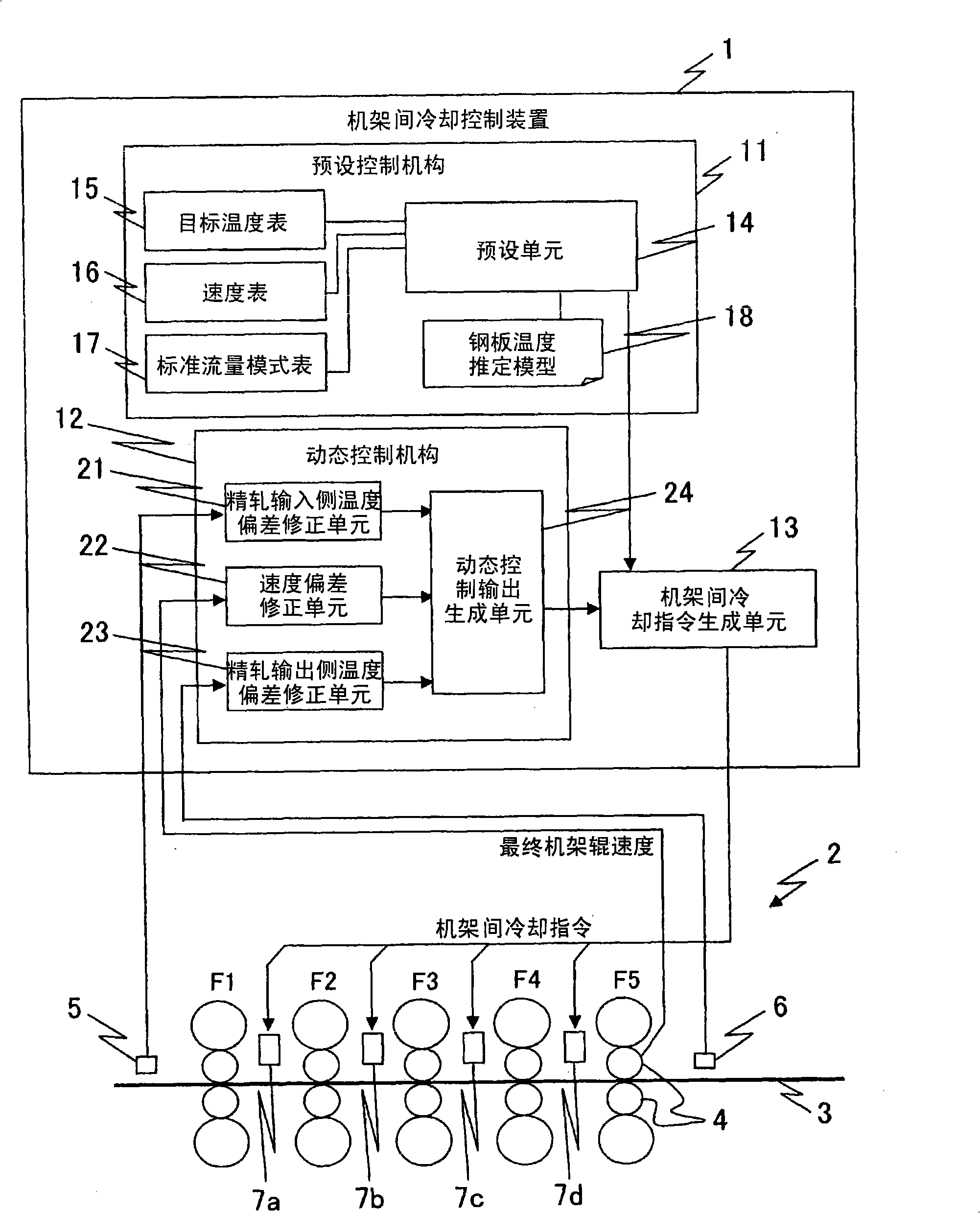

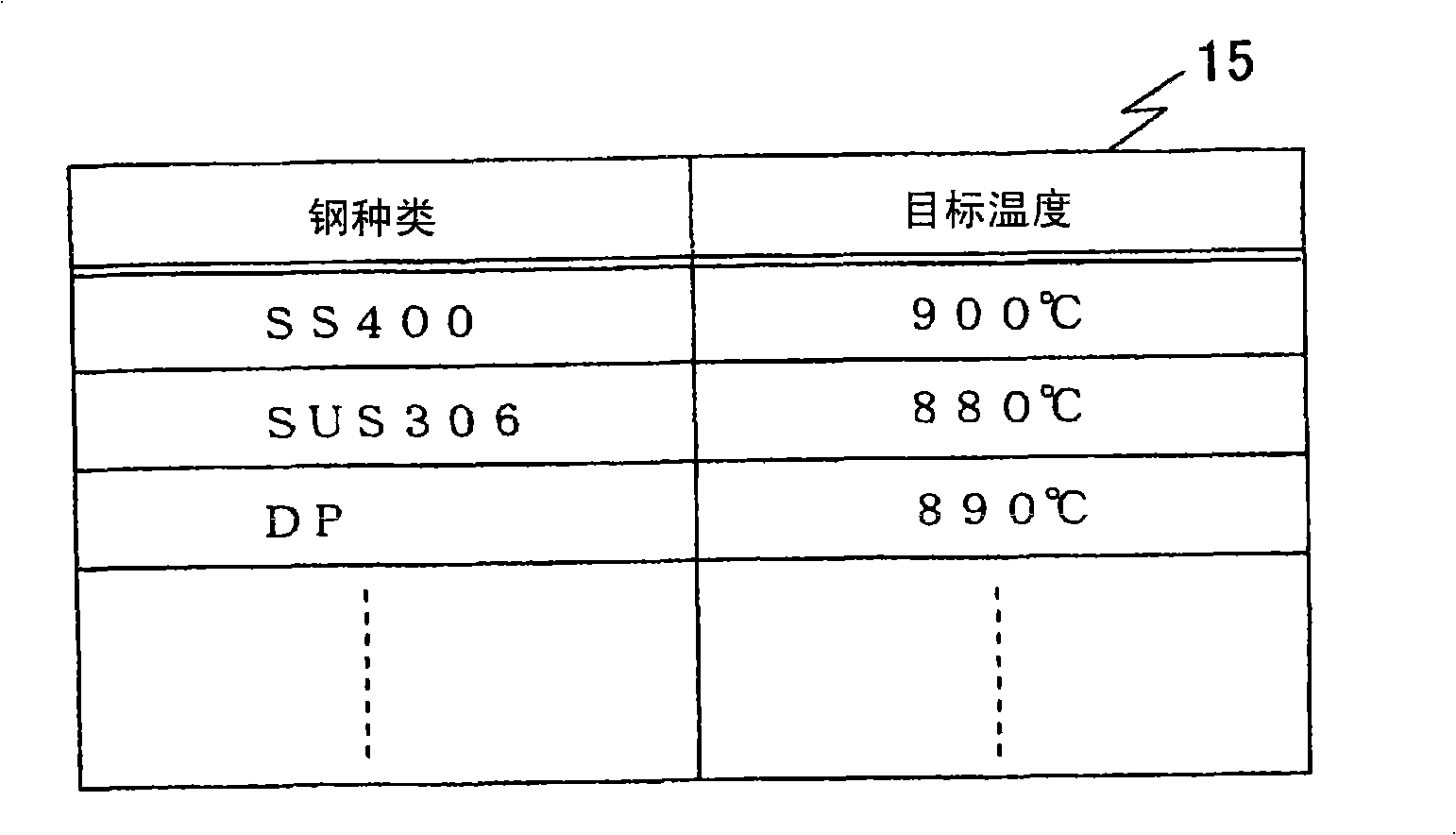

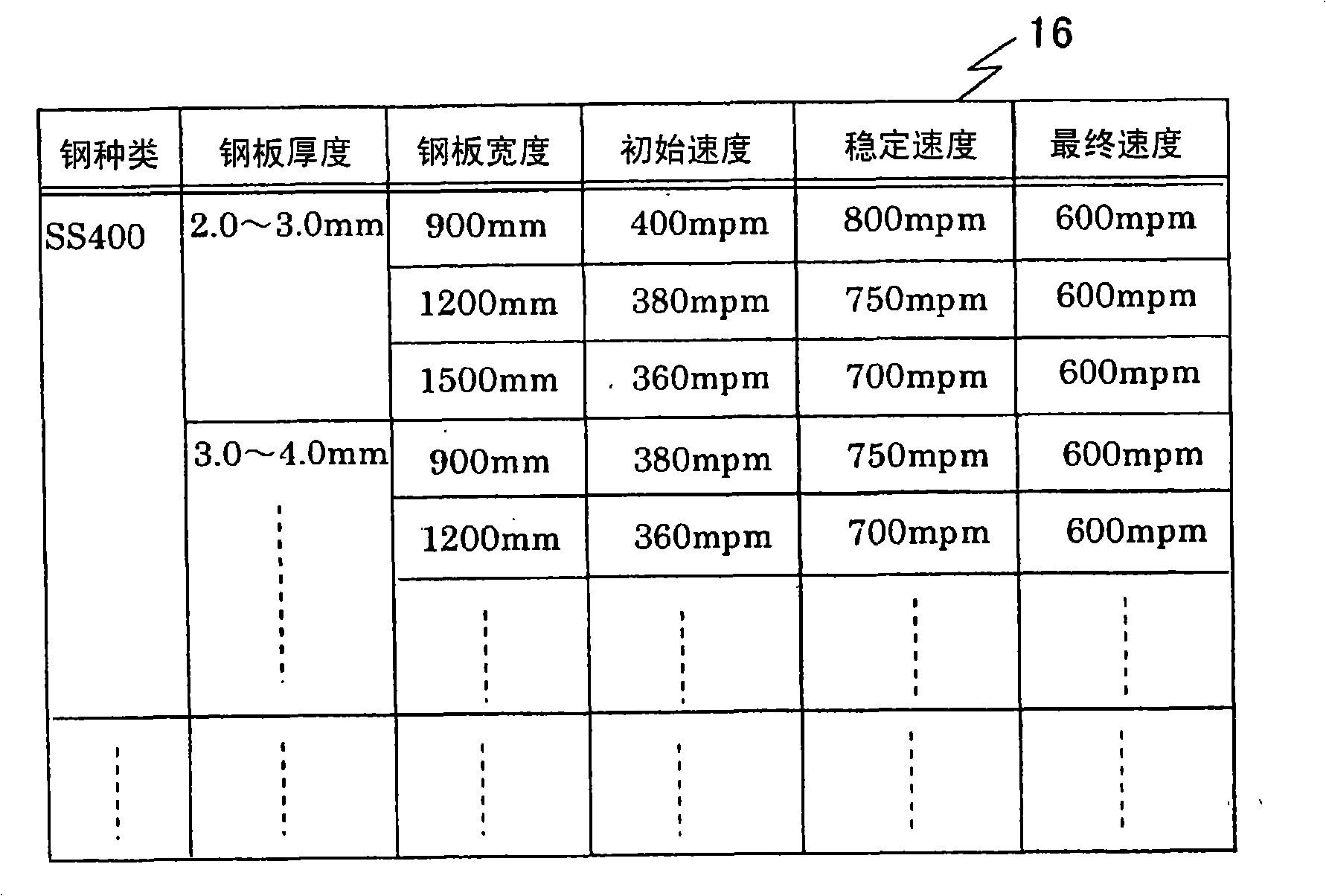

[0071] Next, modes for implementing the present invention will be described. figure 1 It is a figure which shows the structure of the inter-stand cooling control apparatus 1 of 1st Embodiment in connection with the finish rolling mill 2 of a control object. The inter-stand cooling control device 1 receives various signals from the finish rolling mill 2 and outputs control signals to the finish rolling mill 2 . In addition, "... mechanism or unit" described in the following description may also be referred to as "... department".

[0072] The finishing mill 2 includes five stands F1 to F5 (hereinafter, "stand" is omitted as appropriate, and only described with symbols). The steel plate 3 conveyed to the finish rolling mill 2 from a rough rolling mill not shown in the drawing is moved from left to right while being rolled by respective rolls 4 of stands F1 to F5 . In addition, the finish rolling mill 2 is provided with a finish-rolling entry-side thermometer 5, which is a fini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com