Eight-shaft device for tracting locomotive

A technology for traction devices and locomotives, which is applied in traction devices, railway couplings, transportation and packaging, etc., can solve problems such as difficulty in meeting compact space requirements, and achieve reasonable structural layout, improved dynamic performance, and reduced shaft size. The effect of retransfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

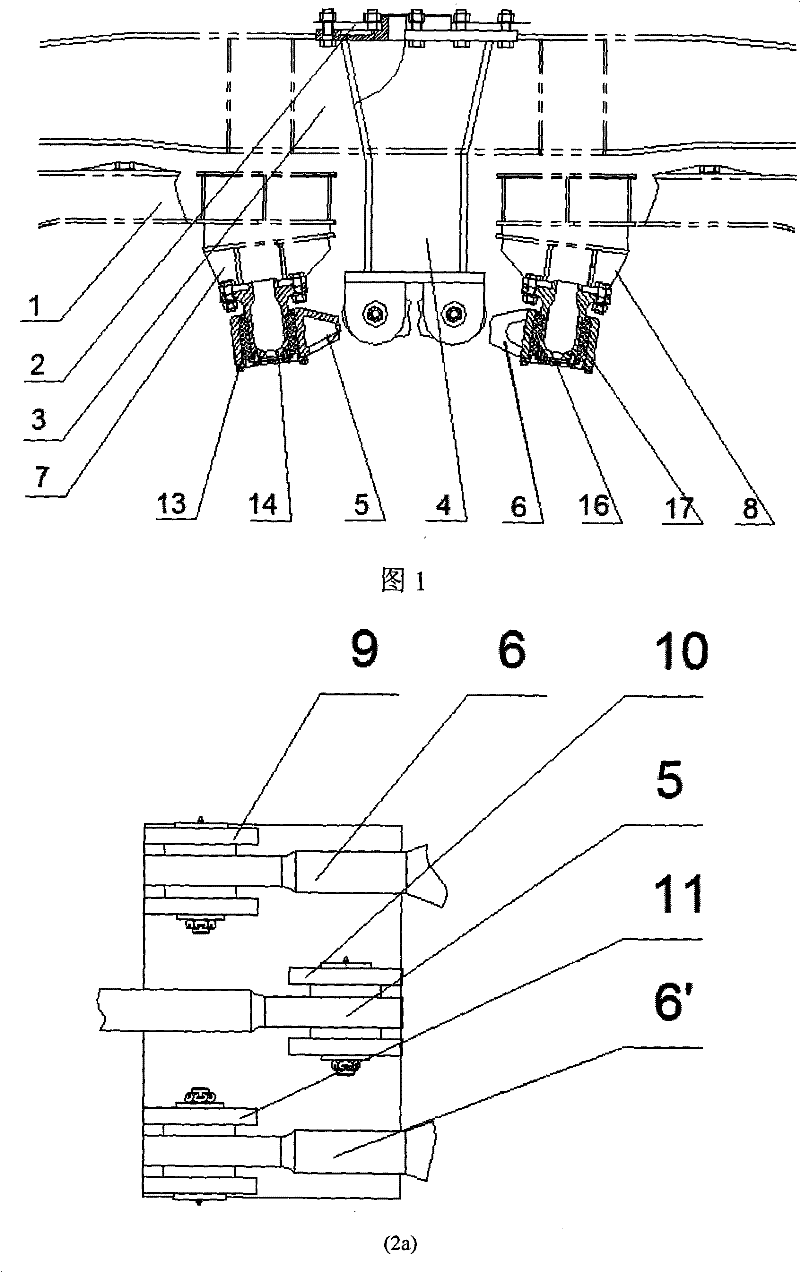

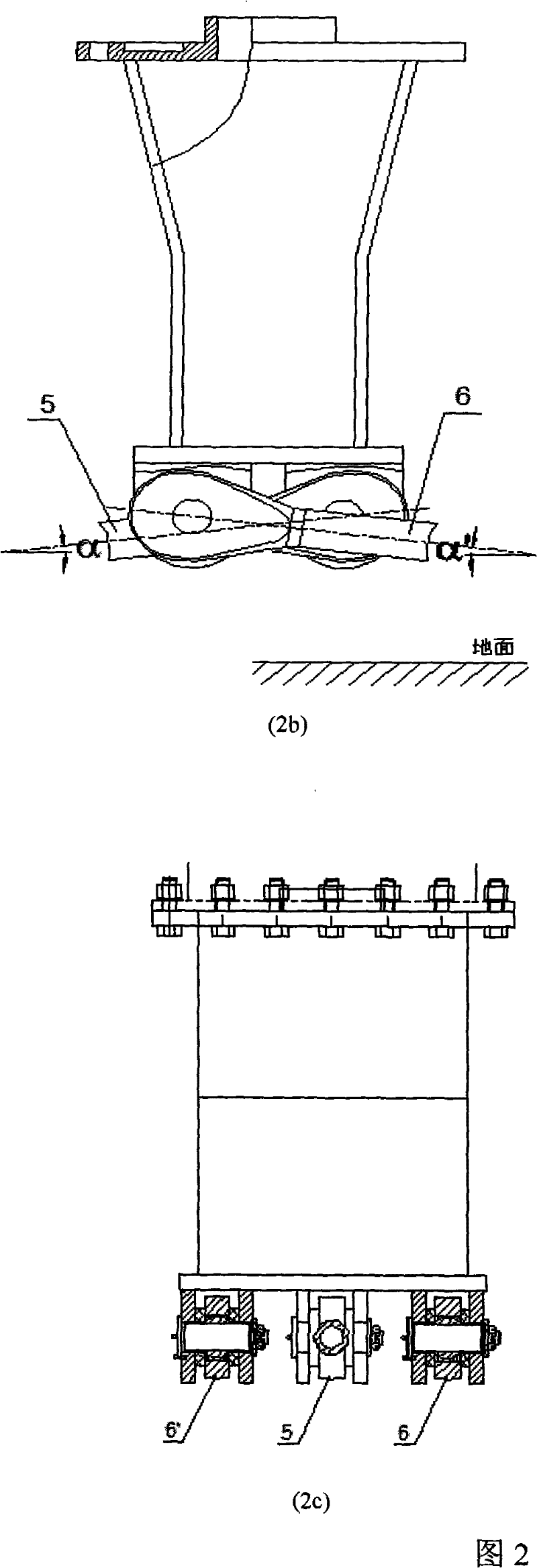

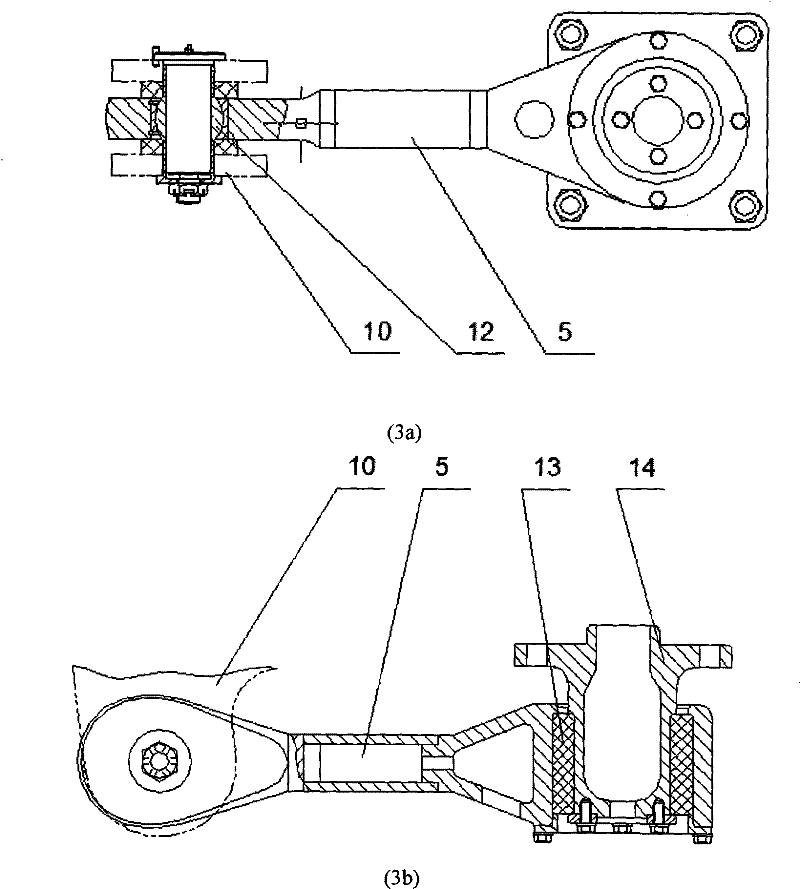

[0012] The whole adopts BOB0-BOB0 axle type, that is, each locomotive has two bogies at the front and rear, and each bogie is composed of two B0 type bogies. The basic structure and specific implementation of the present invention can be seen in conjunction with FIGS. 1 and 2 . In the figure 1-steering frame; 2-car body; 3-intermediate frame; 4-driver seat; 5-single drawbar; 6-double drawbar. The fifth wheel 4 is fixed under the car body 2. The fifth wheel 4 has a set of single drawbars 5 and a set of double drawbars 6 respectively connected to the two bogie end beams 7 and 8 on the locomotive. The traction force is directly transmitted from the frame end beams. To the car body without going through the intermediate frame. There are three lugs 9, 10, 11 on the bottom surface of the structure of the traction seat 4, which are respectively connected with the traction ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com