A detachable and washable seawater desalination device

A kind of equipment and seawater technology, applied in the field of removable and washable seawater desalination equipment, can solve the problems of large occupied area, accident occurrence, system pressure reduction, etc., and achieve the effect of satisfying ship space shortage, prolonging service life, and maintaining stable pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

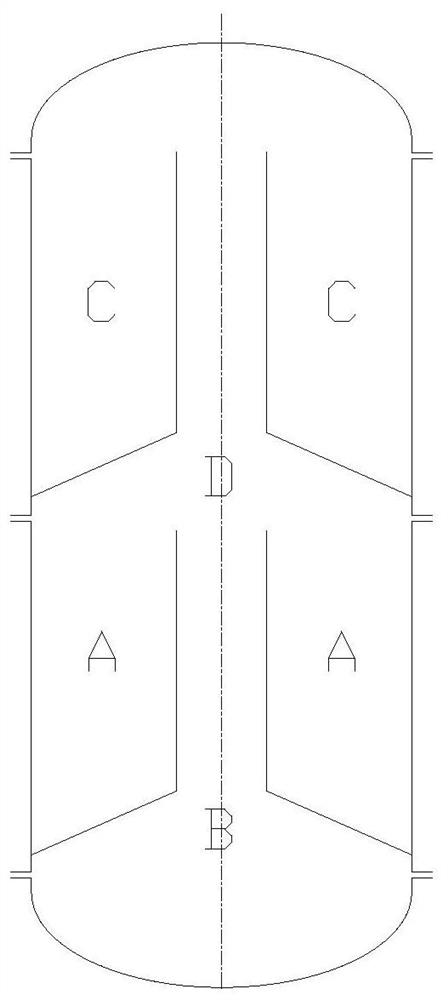

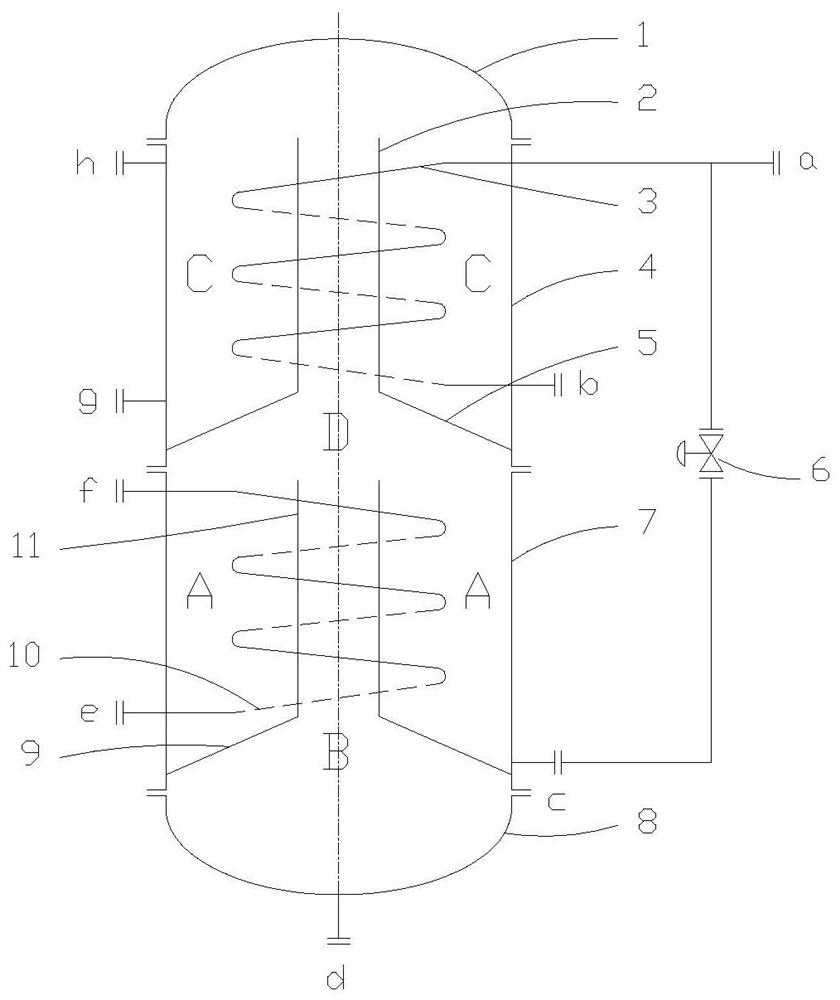

[0033] Such as figure 1 , 2 As shown: the present invention includes an equipment cylinder, which is composed of four parts: an upper head 1, a condensation cylinder 4, an evaporation cylinder 7, and a lower head 8, and a vertical condenser is arranged in the equipment cylinder The central cylinder 2 and the vertical evaporation central cylinder 11, the condensation central cylinder 2 is located above the evaporation central cylinder 11, and an annular condensation partition 5 is provided between the lower end of the condensation central cylinder 2 and the inner wall of the condensation cylinder 4 A ring-shaped evaporation partition 9 is provided between the lower end of the evaporation center cylinder 11 and the inner wall of the evaporation cylinder body 7; the condensation heat exchange tube 3 for entering seawater is arranged around the condensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com