Method for detecting accuracy of optical current transformer for measuring

A technology of current transformers and detection methods, applied in the direction of measuring electric variables, voltage/current isolation, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] 1 Technical requirements for photoelectric transformers

[0048] Photoelectric current transformers must meet all the technical requirements stipulated in the corresponding technical standards or technical conditions. The specific technical requirements are as follows:

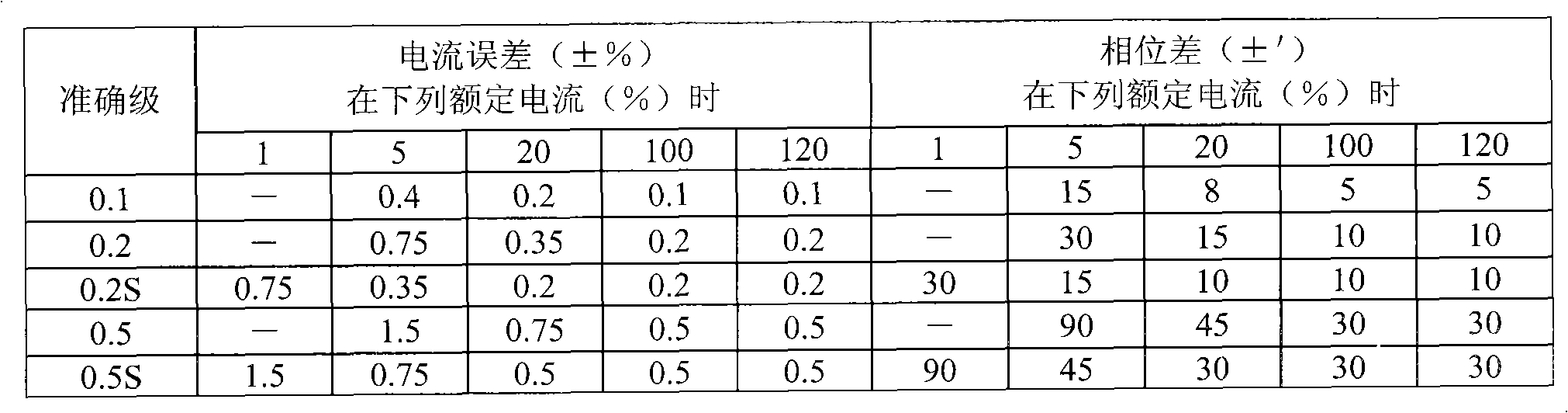

[0049] 1.1 Photoelectric transformer error limit

[0050] 1.1.1 Current transformer for measurement

[0051] At any value under the rated power and rated power factor, the current error (ratio difference and phase difference) of the photoelectric CT measured should not exceed the limits listed in Table 11.

[0052] Table 1 Error limits for measuring CT

[0053]

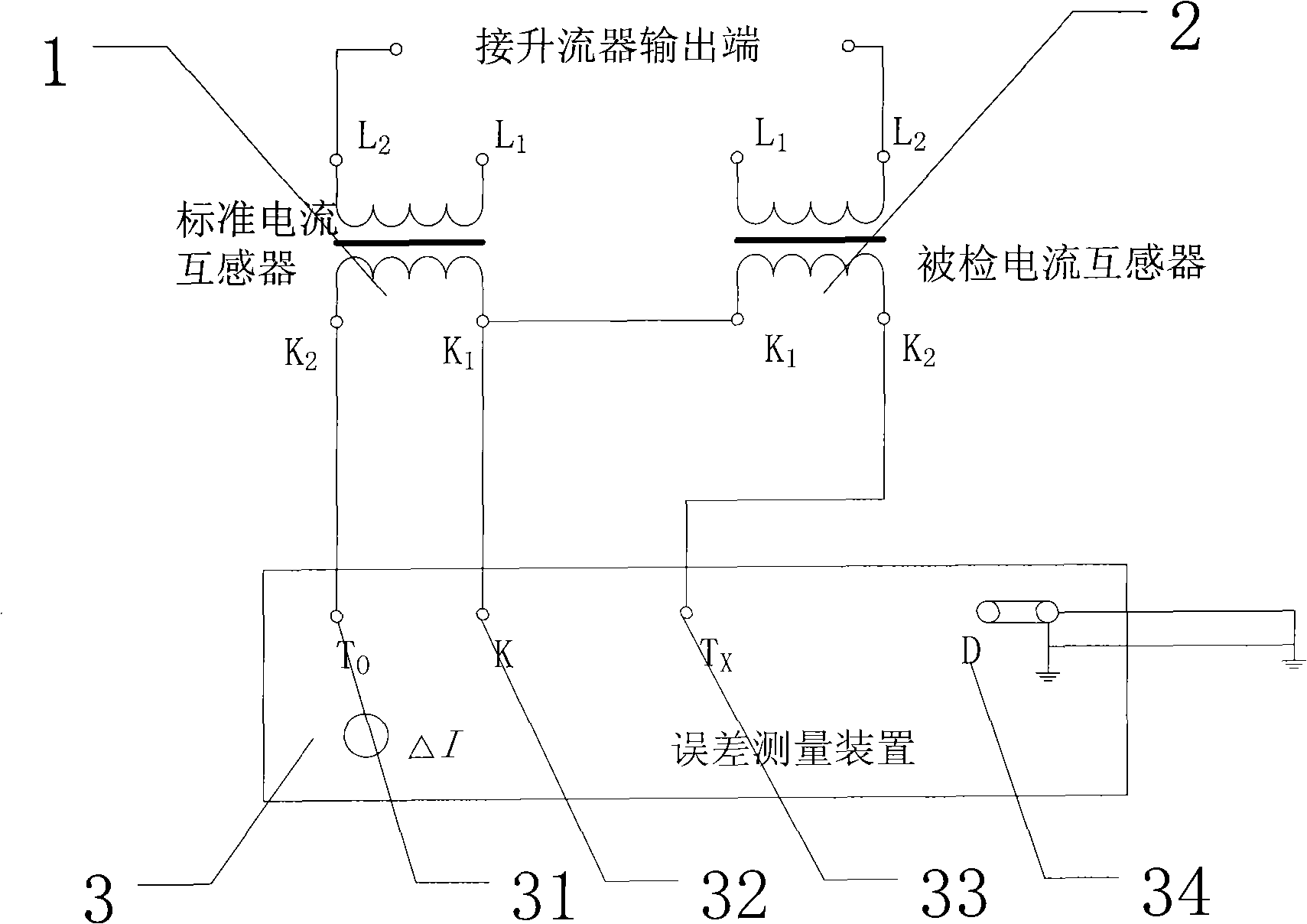

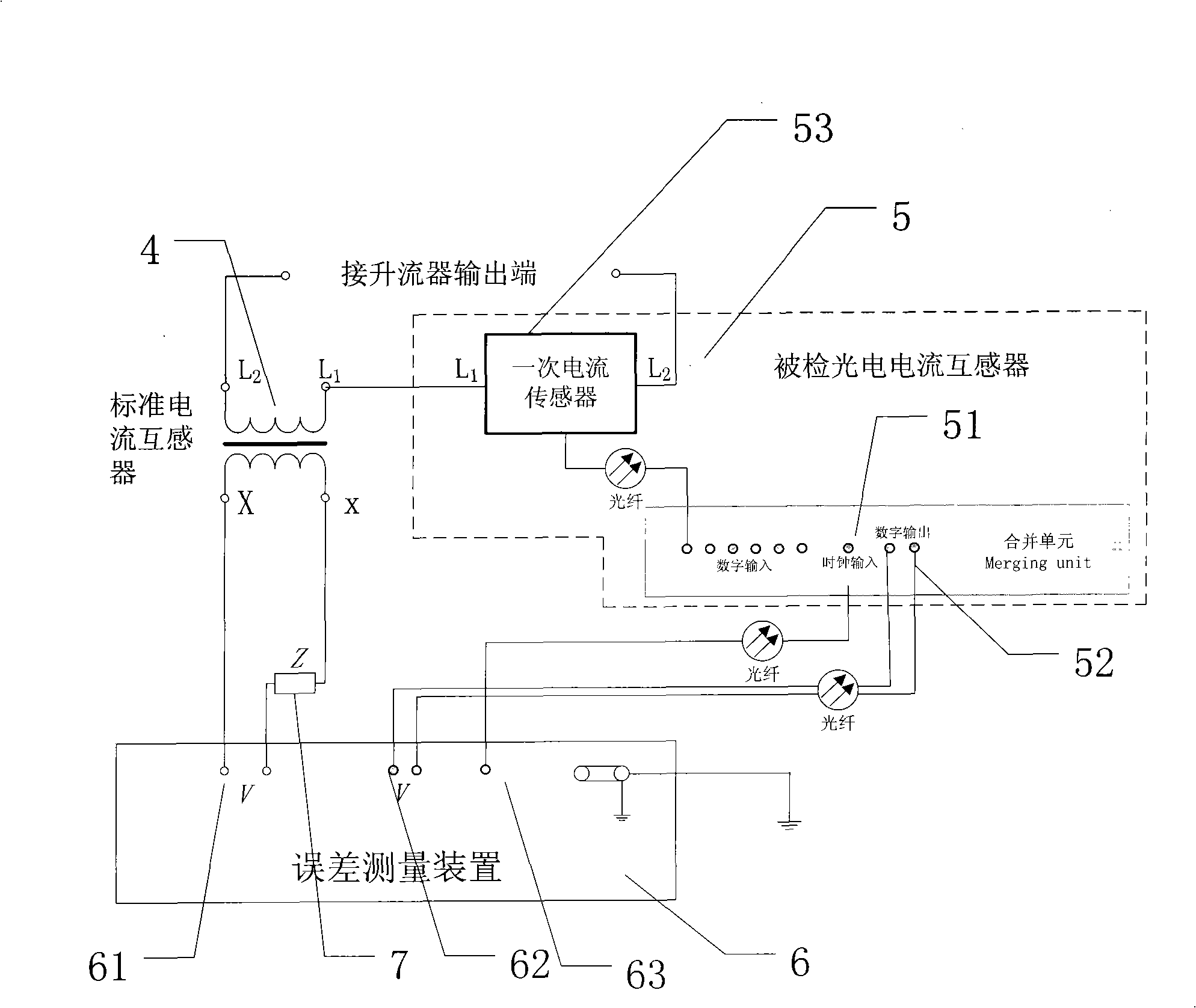

[0054] 2 Verification equipment and conditions

[0055] 2.1 Main equipment

[0056] 2.1.1 Current transformer for measurement

[0057] 2.1.1.1 Standard current transformer or other proportional standard device (hereinafter referred to as current standard device). The accuracy level and technical performance of the current standard should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com