Method for producing acrolein and glycerin-containing composition

A production method and technology of acrolein, applied in the direction of organic chemical methods, carbon-based compound preparation, chemical instruments and methods, etc., can solve a large number of catalysts, the relationship between the yield of acrolein without specific disclosure of contact time, large-scale problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0090] Examples are shown below.

[0091] The methods for calculating the conversion rate of glycerin, the yield of acrolein, and the accumulated amount of carbon substances in Examples are as follows.

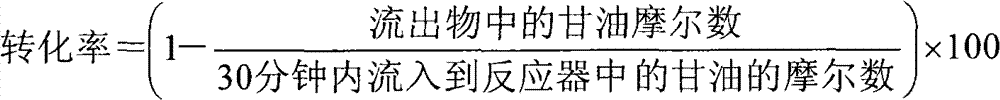

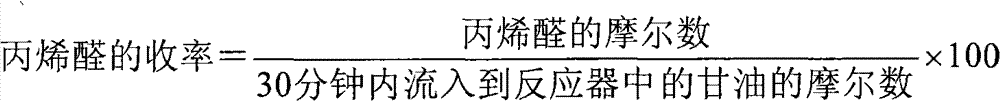

[0092] Conversion rate of glycerin, yield of acrolein:

[0093] The effluent from the reactor described below was qualitatively and quantitatively analyzed by gas chromatography (GC). The conversion rate and the yield of acrolein were calculated from the quantitative analysis results and the following formula (1) or (2).

[0094] Formula 1):

[0095]

[0096] Formula (2):

[0097]

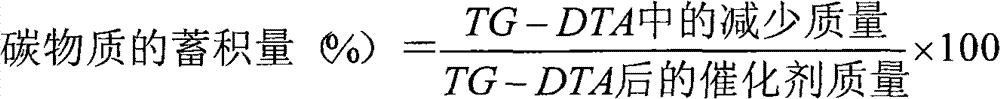

[0098] The accumulation of carbon substances:

[0099] The amount of carbon substances attached to the catalyst after acrolein production was measured by thermogravimetric-differential thermal analysis (TG-DTA). In this TG-DTA, the catalyst was placed under air circulation, the temperature was raised from room temperature to 600° C. at 10° C. / min, and the temperature of 600° C. was maint...

preparation example A

[0104] 49 g of 85% by mass orthophosphoric acid was mixed in a solution of 160 g of aluminum nitrate nonahydrate and 800 g of ion-exchanged water. After dropping 96.7 g of 28% by mass ammonia water to this mixed solution over about 50 minutes (a white precipitate was formed from the beginning of the dropping), the mixed solution was stirred for 1 hour. Next, the solid matter (precipitate) separated from the mixed liquid by suction filtration was washed. The washing includes: after mixing the solid matter and 800 g of ion-exchanged water, stirring it for 1 hour, and then standing still for 1 hour, and then separating the solid content by suction filtration. The solid matter obtained by repeating the washing operation three times was dried overnight at 120° C. in an air atmosphere, and then fired at 1,200° C. for 3 hours in an air atmosphere. The obtained solid matter was crushed and classified into 0.7-1.4 mm to obtain catalyst A.

preparation example B

[0106] Dissolve 0.58g of NaOH in 15.00g of distilled water, then add 1.95g of NaAlO 2 (manufactured by Asada Chemical Industry Co., Ltd., purity: 86.8% by mass) was dissolved in distilled water, and 10.15 g of a 40% by mass aqueous solution of tetra-n-propylammonium hydroxide was added to the distilled water. Then, distilled water was added to this solution to prepare an impregnation solution with a total amount of 30 ml. Then, silicon beads ("Ciyaliakto Q-50" manufactured by Fuji Silysia Chemical Co., Ltd., 10-20 mesh, average pore diameter: 50 nm) were used as the silicon molded product, and 30 g of the silicon beads obtained by drying at 120° C. for 1 day were placed in the impregnating solution. Soak for 1 hour. Then, the silica beads were dried on an evaporating dish set on a water bath at 100°C, and then dried at 80°C under a nitrogen stream for 5 hours, thereby allowing the Na and Al crystallization agents required for crystallization to be supported on the silicon bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com