Machine tool protection system of precision grinding machine

A technology for protection systems and precision grinding machines, applied in grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc., can solve processing waste and coolant splashes, serious pollution of processing areas, machine tool injury accidents To achieve the effect of clean and safe operation, convenient and safe operation, ensuring cleanliness and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

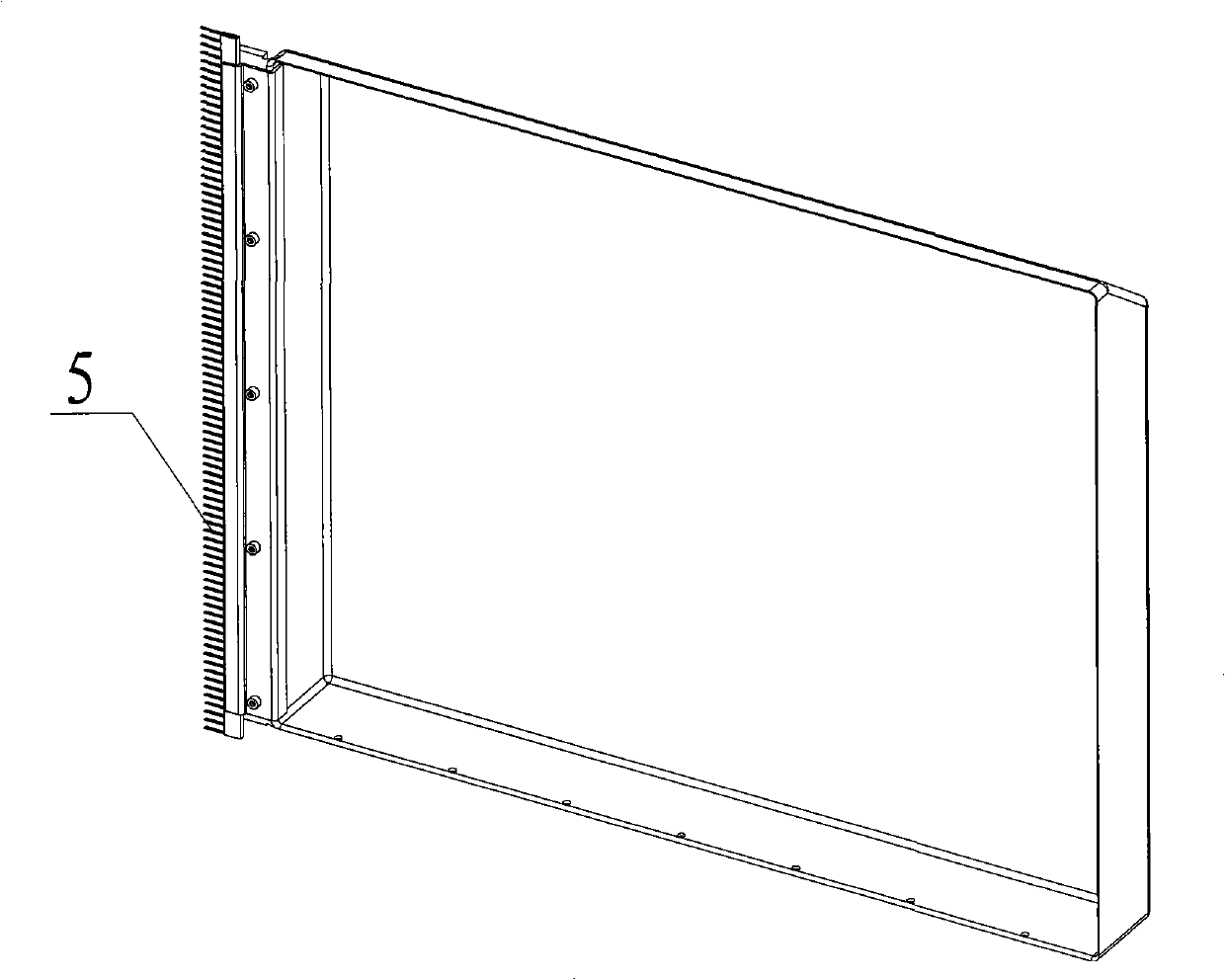

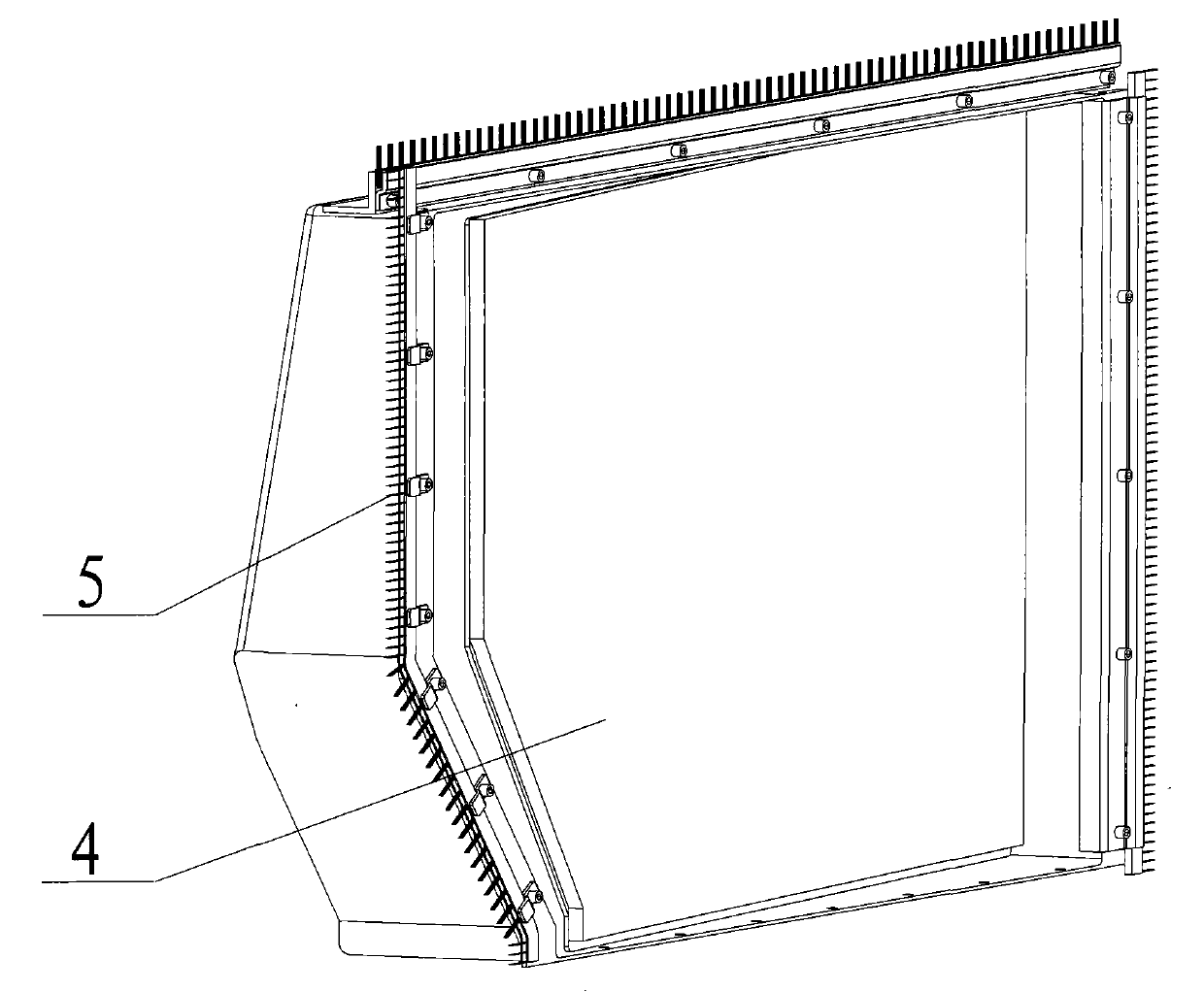

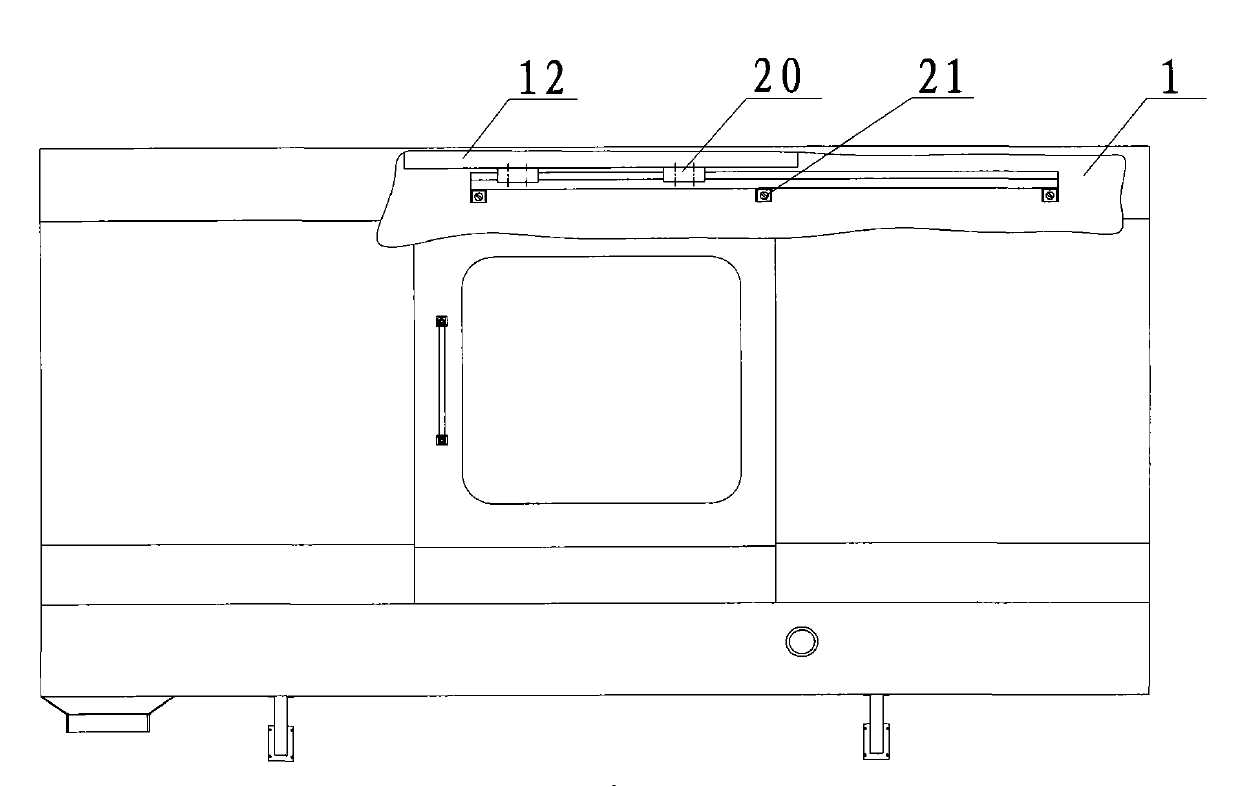

[0024] see Figure 1-9 , the embodiment of the present invention is provided with peripheral sheet metal fully enclosed protective cover 1, left baffle plate 2, right baffle plate 3, cushion 4, scraping brush 5, bed rail protective cover (comprising bed rail leather tiger protective cover 6 and bed guide rail sheet metal protective cover 7), screw mandrel sheath 8, line rail protective cover (including column base linear guide rail protective cover 9 and column linear guide rail protective cover 10) and screw mandrel protective cover 11. The peripheral sheet metal fully enclosed protective cover 1 is equipped with a sliding door 12, a guide rail 13, an electric control button 14, an observation window 15, an expansion plate 16, a cutting fluid filter interface 17, an air inlet / outlet 18 of the oil and water mist purification device, and a support Fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com