Method for positioning concrete turnout sleeper embedded sleeve pipe

A positioning method and concrete technology, which are applied to ceramic molding machines, manufacturing tools, etc., can solve the problems that the positioning method is not easy to meet the accuracy requirements and inconvenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

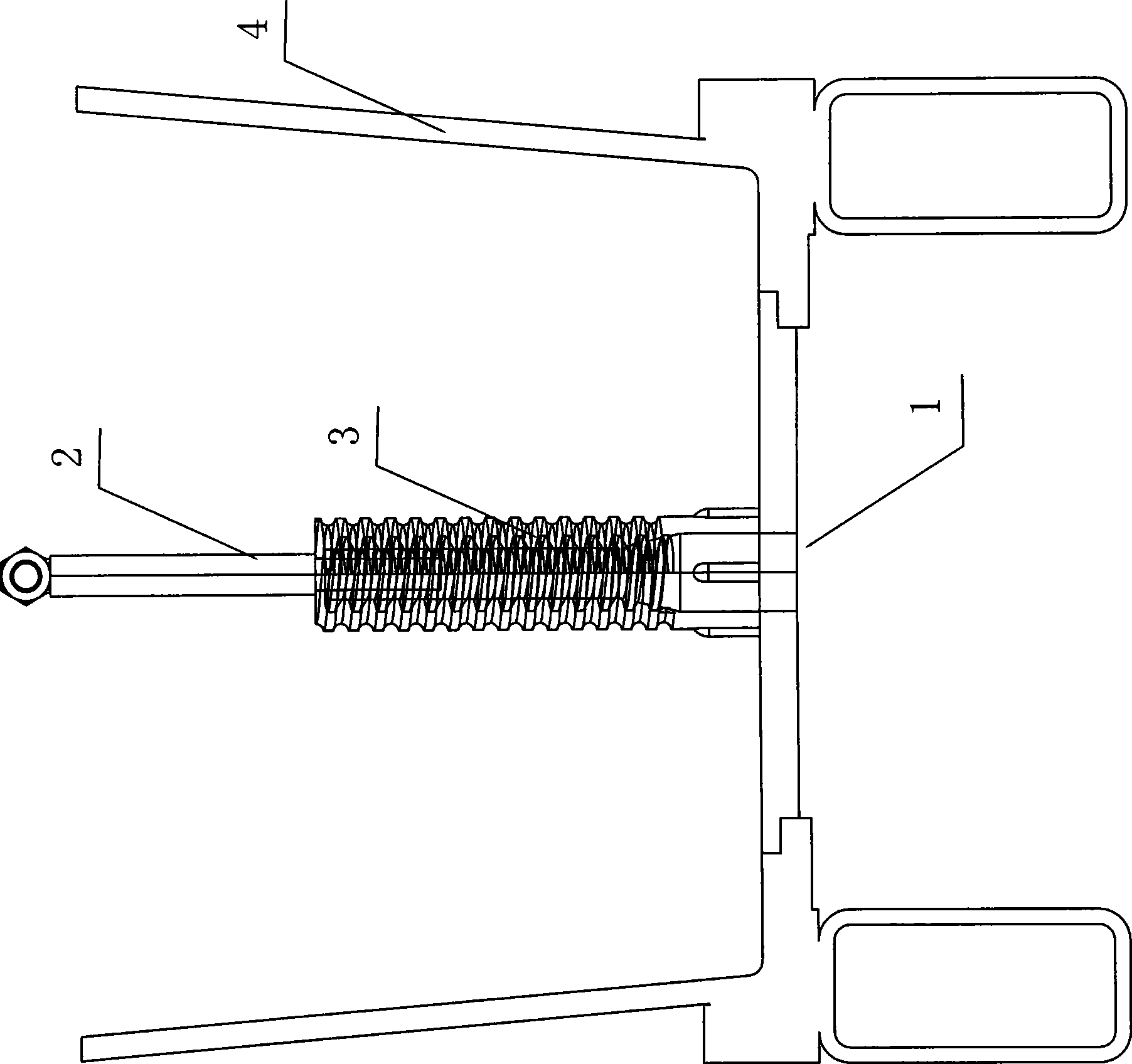

[0020] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0021] The positioning method of the pre-embedded casing of the concrete turnout sleeper has the following steps:

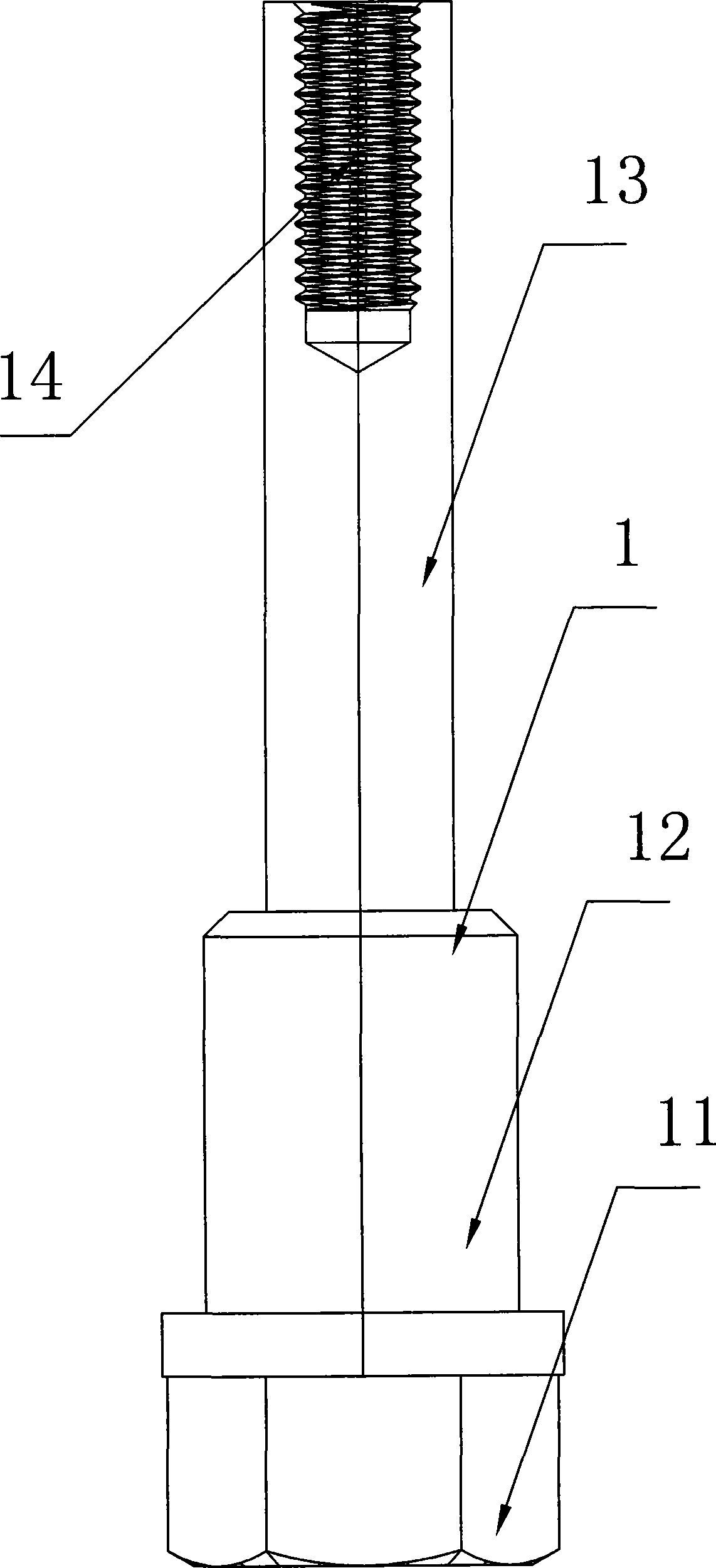

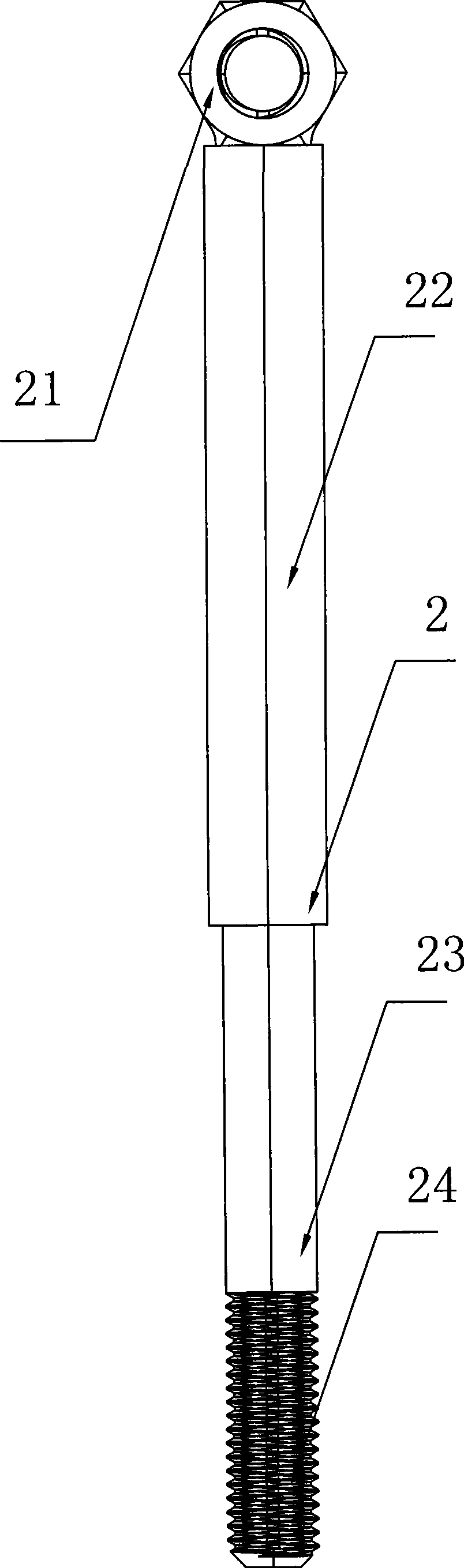

[0022] a. According to the shape and inner diameter of the pre-embedded casing, the size of the matching upper positioning shaft, lower positioning shaft and positioning hole on the bottom plate of the switch sleeper model shell is designed. One end of the upper positioning shaft has a thread, and the lower positioning shaft One end has a matching internal thread hole; or one end of the lower positioning shaft has a thread, and one end of the upper positioning shaft has a matching internal thread hole;

[0023] b. During the production process of the switch sleeper, the embedded casing is installed on the bottom plate of the model shell before the concrete is poured in the model shell of the switch sleeper;

[0024] c. Insert the low...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap