Injector

A technology of injectors and nozzles, which is applied in the direction of fuel injection devices, machines/engines, engine components, etc., can solve the problems of unavoidable costs, increased attractiveness, and rising costs, and achieve high efficiency and stable fuel injection. Controlling, attractive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

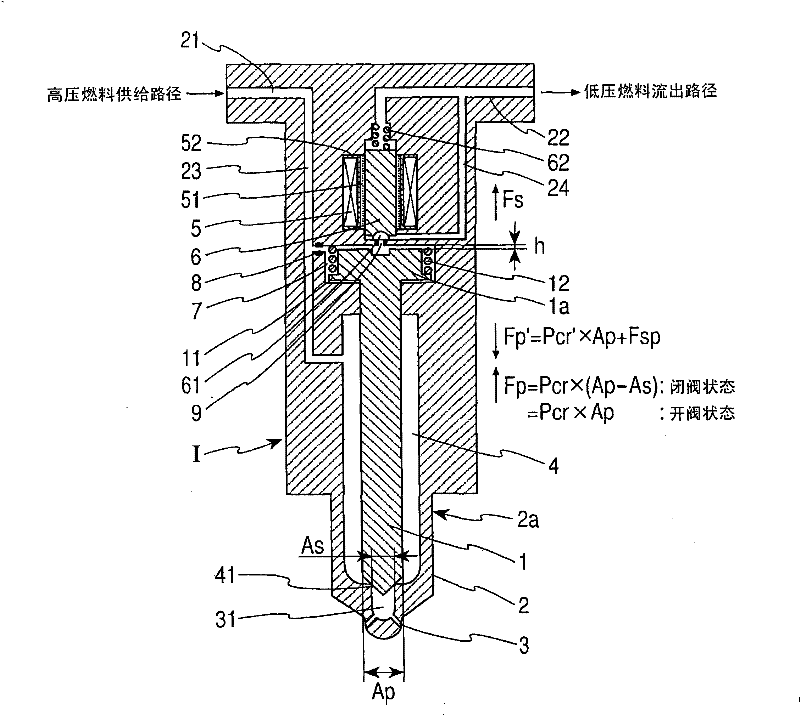

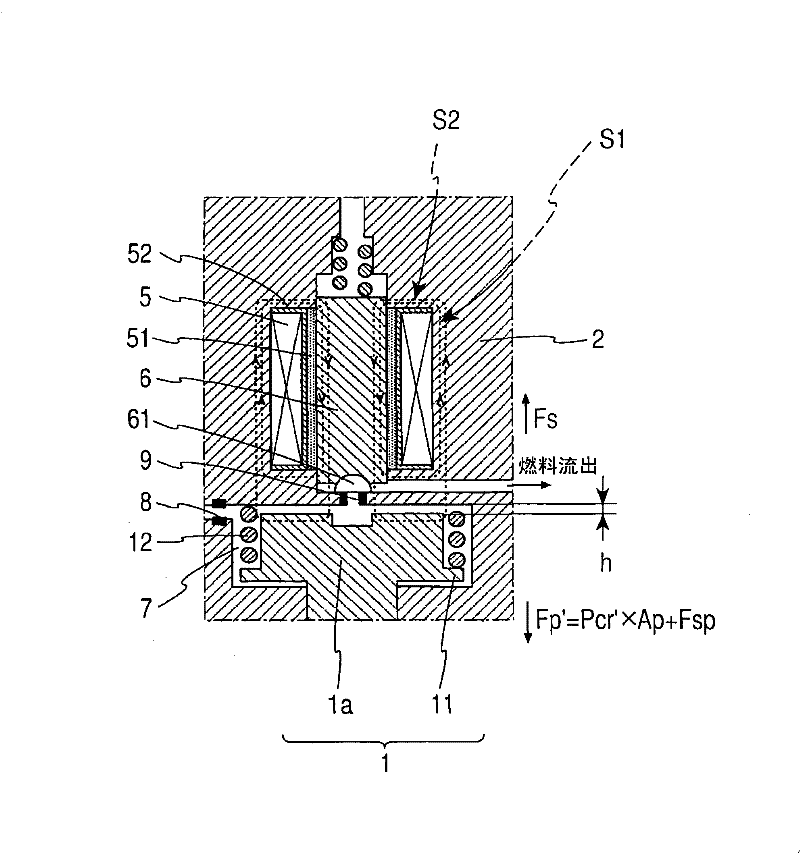

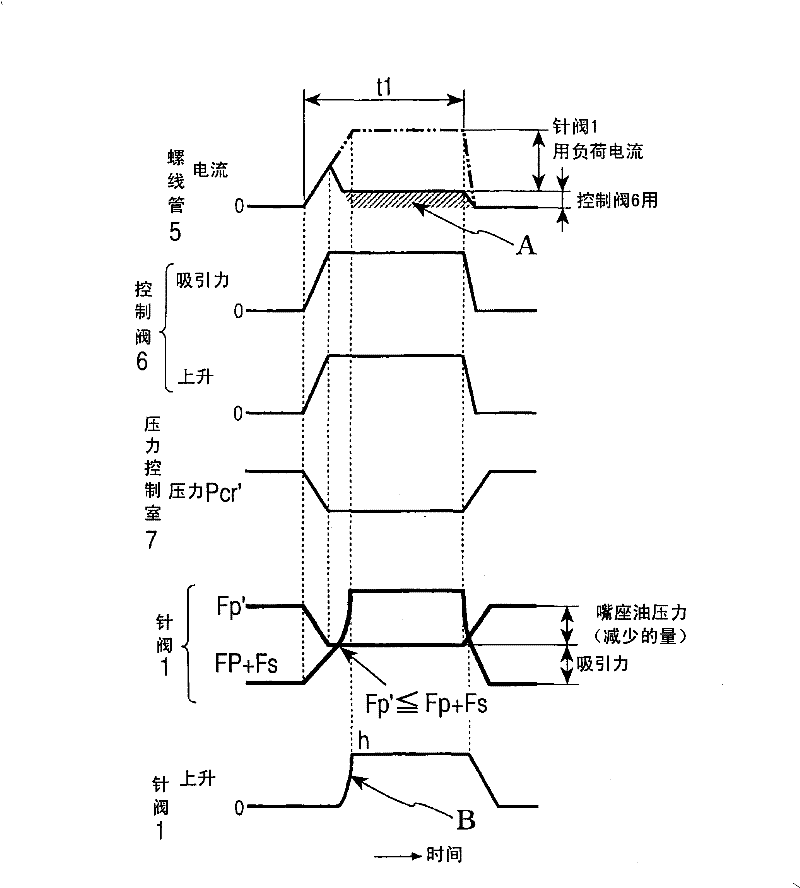

[0051] figure 1 It is an overall sectional view showing the general structure of the injector 1 of the present invention, figure 2 is an enlarged cross-sectional view showing its main part structure, image 3 It is a timing chart showing an example of fuel injection control.

[0052] The injectors 1 are applied to, for example, an accumulator fuel injection device for a diesel engine, and are provided one-to-one for each cylinder of the internal combustion engine. In a common rail (not shown) that is a pressure accumulator common to each injector I, fuel pressurized to a high pressure by a high-pressure feed pump (not shown) is accumulated, and the control device (ECU, not shown) controls the The entire device is controlled so as to obtain the optimum injection amount and injection timing corresponding to the operating state of the internal combustion engine. As the fuel to be pressurized in the common rail, liquefied fuel such as dimethyl ether (DME) or liquefied petroleu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com