Recovery of hydrocarbons from a gaseous stream

a gaseous stream and hydrocarbon recovery technology, applied in the petroleum industry, gas contaminants removal, combustible gas purification, etc., can solve the problems of high energy consumption, high energy consumption, and high cost of cryogenic processes, and achieve the effect of reducing the pressure of the fuel gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

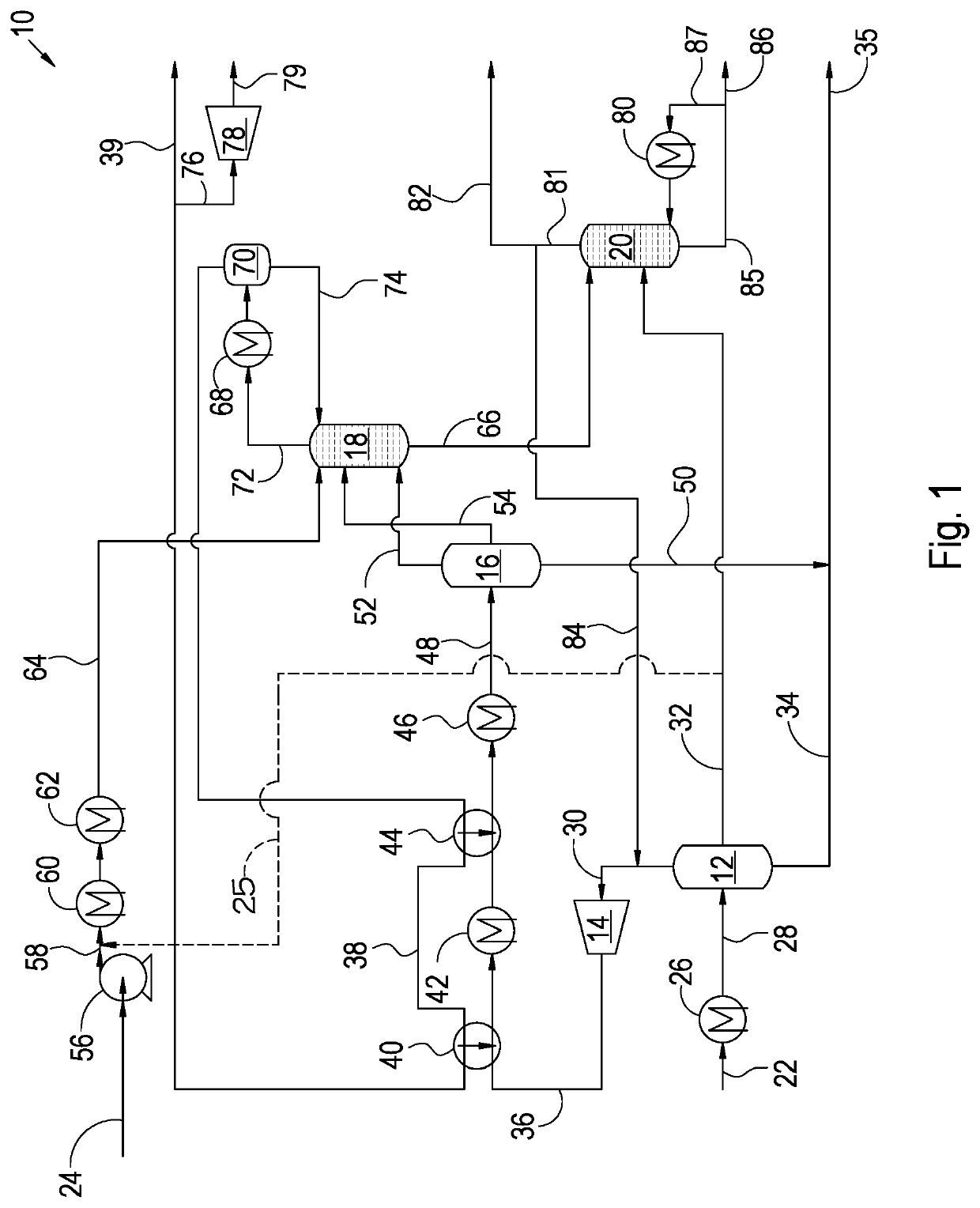

[0073]The invention will now be described, by way of example, with reference to the accompanying diagrammatic drawing which shows one embodiment of a process to recover hydrocarbons from a Fischer-Tropsch tail gas in accordance with the invention.

[0074]In the drawing, reference numeral 10 generally indicates a process for the recovery of hydrocarbons from a Fischer-Tropsch tail gas in accordance with the invention.

[0075]The process 10 broadly includes a first separator 12, a tail gas compressor 14, a second separator 16, a sponge oil column 18 and a carbon-dioxide stripper 20.

[0076]A Fischer-Tropsch tail gas 22 and a Fischer-Tropsch hydrocarbon condensate 24 are withdrawn from a three-phase gas-liquid separator (not shown) located downstream of a Fischer-Tropsch synthesis reactor and also downstream of an air cooler (also not shown). The air cooler and the three-phase gas-liquid separator are respectively used to cool the gaseous overhead product of a Fischer-Tropsch reactor and to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com