Multi-mode piezoelectric normally closed electronically controlled unit pump

A piezoelectric, multi-mode technology, used in fuel injection pumps, engine components, machines/engines, etc., can solve the problems of injector damage, poor safety, and low work efficiency, reduce harmful emissions, and improve response speed. , the effect of high movement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

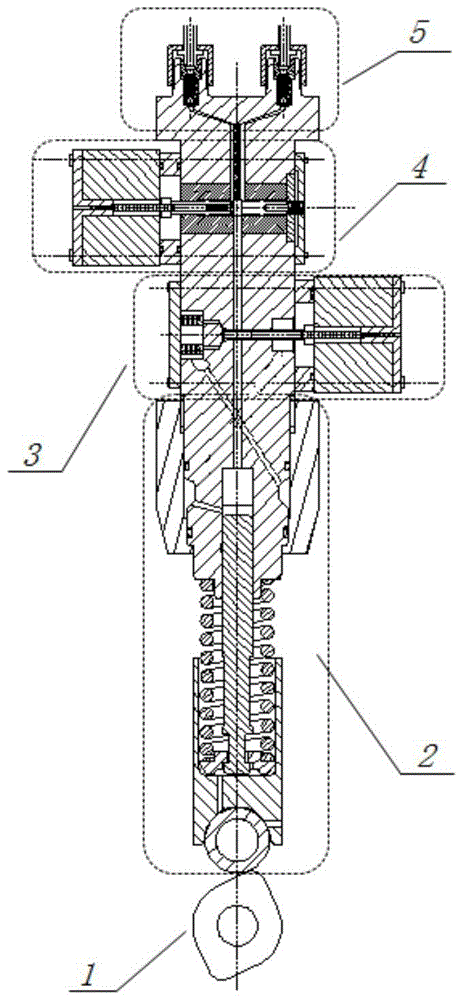

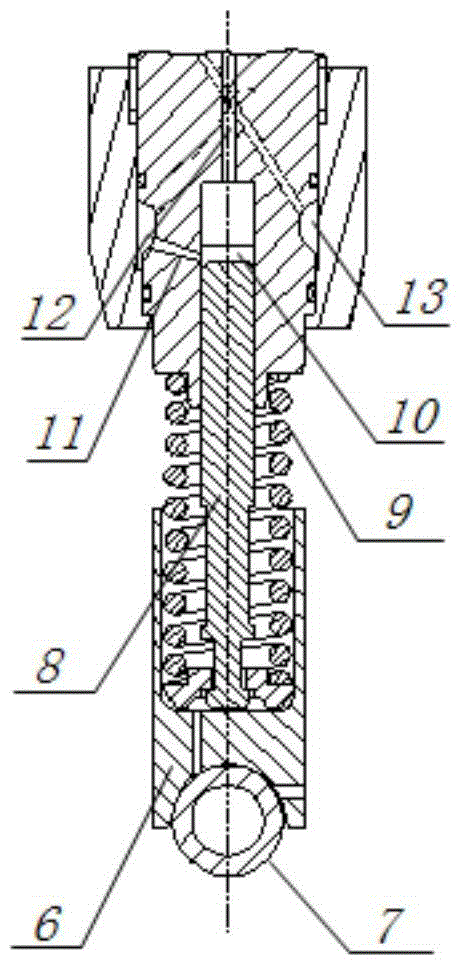

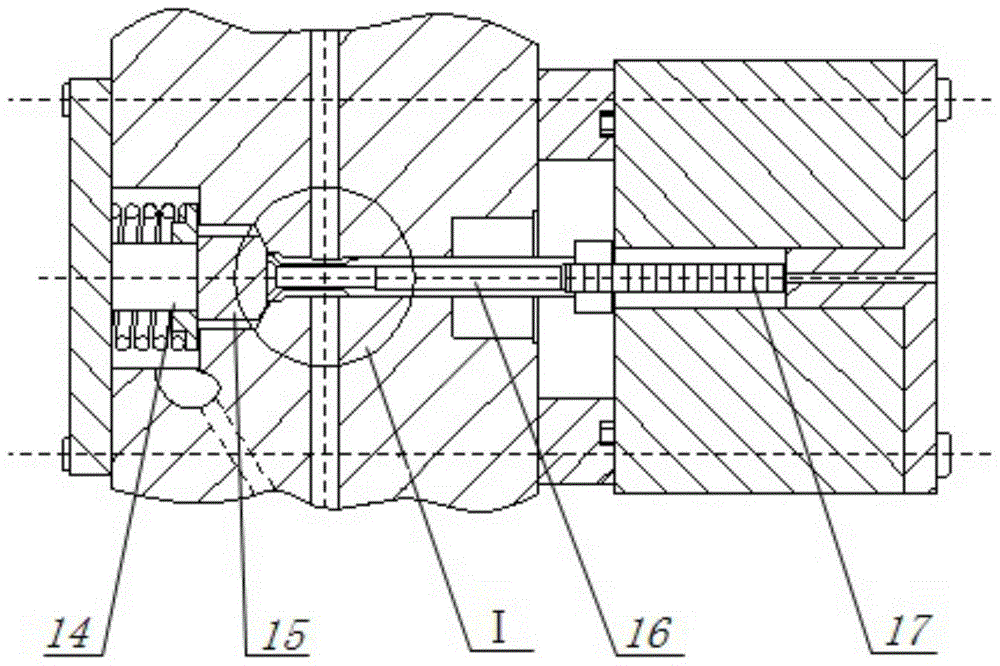

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0019] combine Figure 1-6 , The device consists of double peach cam 1, roller plunger 2, normally closed piezoelectric fuel control valve 3, fuel oil circuit reversing valve 4 and double oil outlet valve 5. The roller plunger 2 is installed at the bottom of the pump body 6 and is composed of a roller 7, a plunger 8, a plunger spring 9, a plunger chamber 10, an oil inlet 11, an oil circuit 12 and an oil discharge oil circuit 13. A normally closed piezoelectric fuel control valve 3 is installed above the plunger chamber 8 , including an oil relief poppet valve spring 14 , an oil relief poppet valve 15 , a control valve stem 16 and a piezoelectric crystal 17 . The fuel oil circuit reversing valve 4 is installed above the normally closed piezoelectric fuel control valve 3, which includes a piezoelectric crystal 20, a front reversing valve stem 21, a reversing valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com