A method for controlling a fuel supply system

A fuel input and fuel technology, applied in electrical control, engine control, fuel injection control, etc., can solve problems such as the inability to achieve closed-loop operation or closed-loop control of BLDC motors, problems with motor starting and operation, and the inability of the rotor to follow the rectifier. The effect of shortening the waiting time, avoiding the start-up delay, avoiding the delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

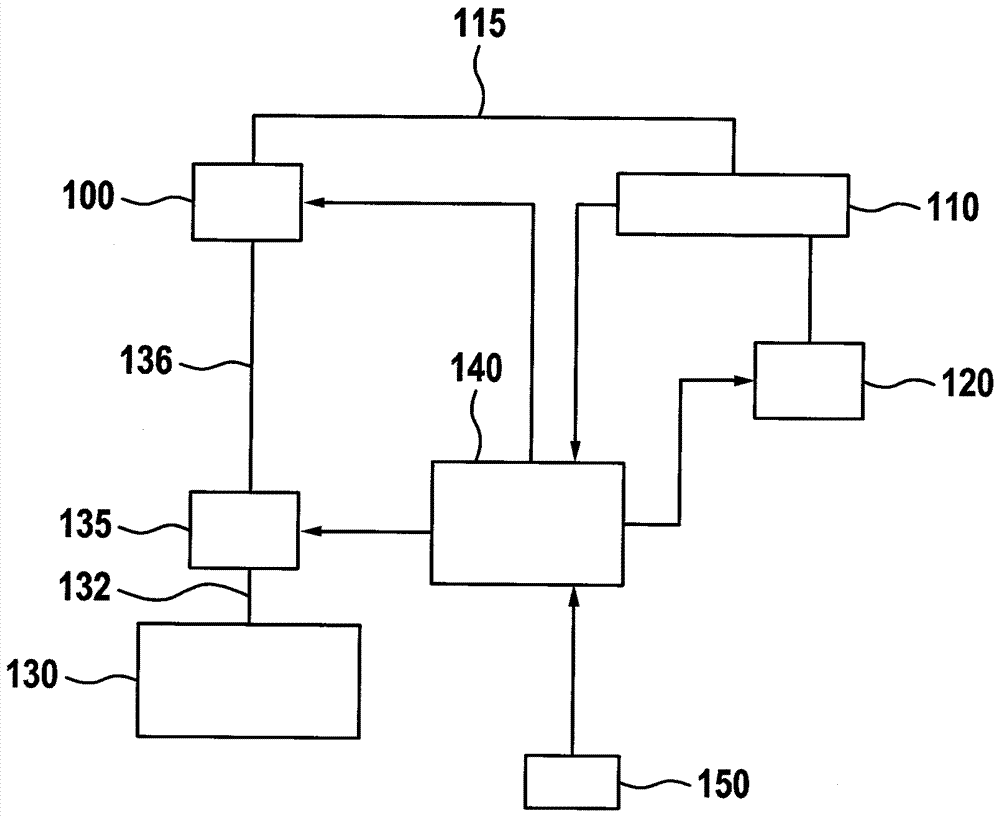

[0030] figure 1Shown in is a block diagram of a preferred embodiment of the fuel input system of the present invention. Use 100 to represent the high pressure pump. The high-pressure pump conveys fuel from the low-pressure region into the high-pressure region. This high-pressure area essentially contains a high-pressure accumulator 110 , known as a pressure accumulator, and a high-pressure inlet line 115 contained between the high-pressure pump 100 and the high-pressure accumulator 110 . Fuel enters the combustion chamber of the internal combustion engine from the high-pressure accumulator 110 via the injector 120 .

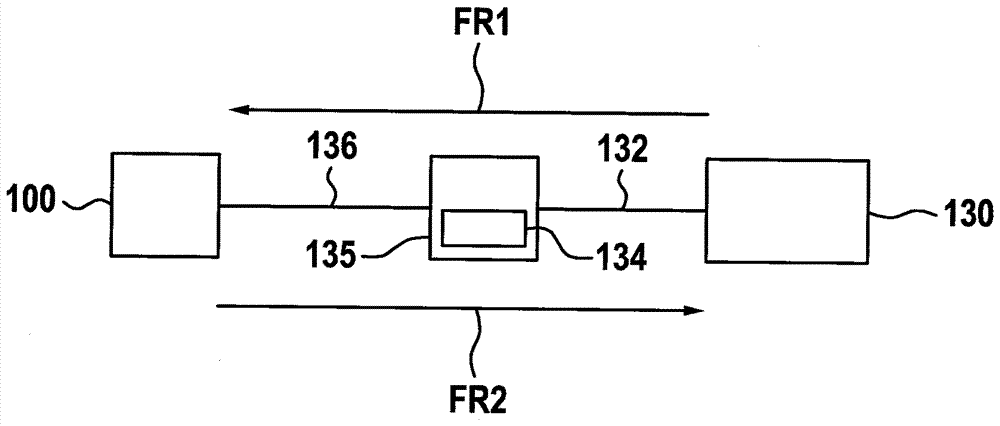

[0031] Furthermore, the high-pressure pump 100 is connected to a low-pressure area which essentially contains a low-pressure accumulator 130 , also called a tank. In addition, this low-pressure region contains fuel pump 135 , which in the embodiment described is designed as a low-pressure fuel pump. Specifically, the low pressure fuel pump 135 is driven by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com