Method and device for detecting structural abnormalities in a spherical particle, mainly in a nuclear fuel particle for high temperature or very high temperature reactors

A spherical particle, particle technology, used in reactors, measurement devices, nuclear reactor monitoring, etc., can solve problems such as presence and position sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

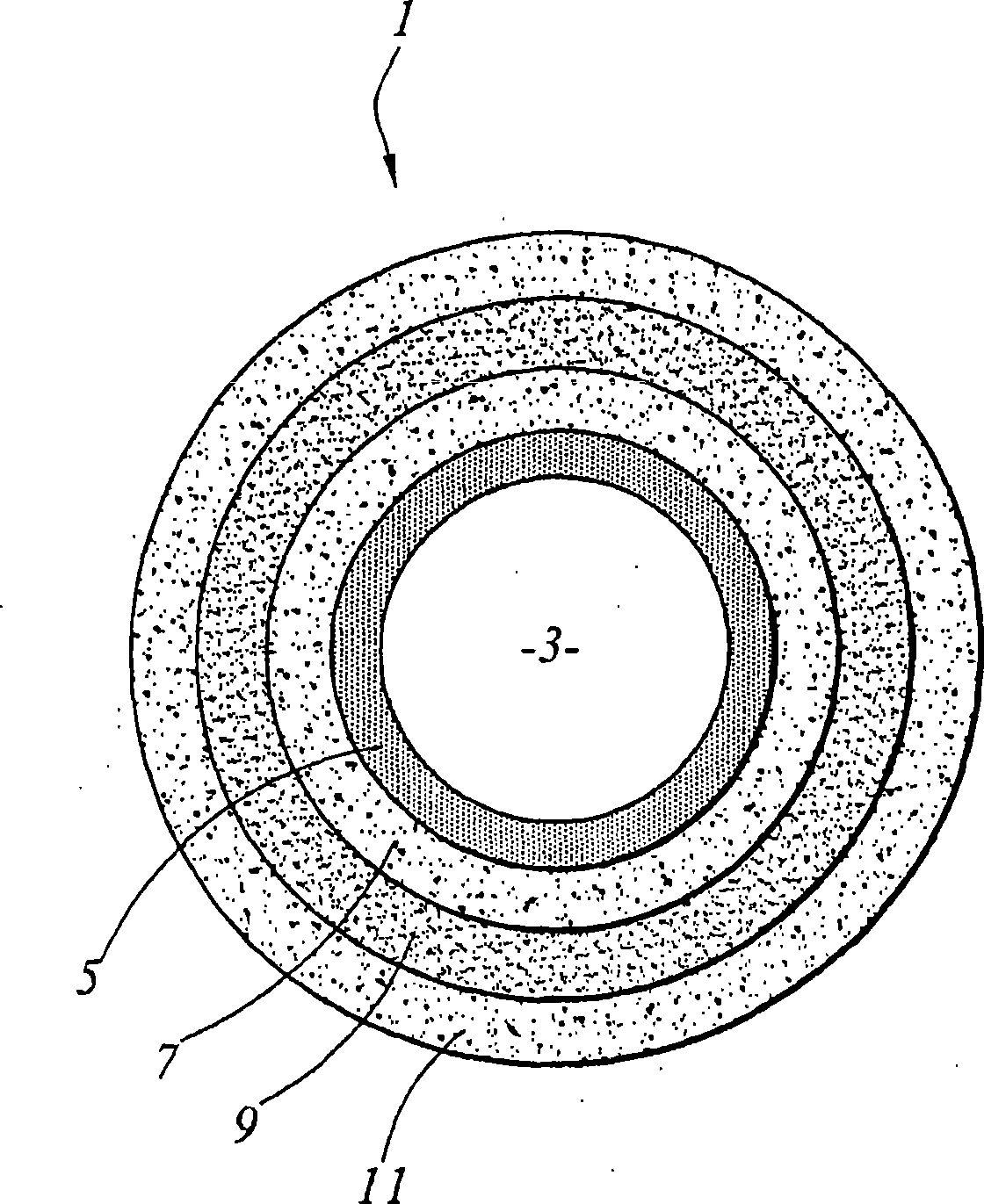

[0033] figure 1 The structure of nuclear fuel particles 1 for high temperature or very high temperature reactors (HTR / VHTR) is schematically illustrated.

[0034] Conventionally, the particle 1 is generally substantially spherical, and contains continuously from the inside to the outside:

[0035] - Fissile material core3, e.g. based on UO 2 or UCO,

[0036] - porous pyrolytic carbon layer (pyrocarbon) 5,

[0037] - dense first pyrolytic carbon layer 7,

[0038] - silicon carbide layer 9 and

[0039] - A dense second pyrolytic carbon layer 11 .

[0040] When using such particles, the porous pyrolytic carbon acts as a reservoir for the fission gas, the silicon carbide acts as a barrier to prevent the diffusion of solid fission products, and the dense pyrolytic carbon ensures mechanical resistance to the pressure of the fission gas.

[0041] The core 3 has, for example, a diameter of approximately 500 μm, and the thicknesses of the layers 5 , 7 , 9 and 11 are, for example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com