Method for hoisting ultra-high overweight equipment in closed workshop and special sling

A kind of hoisting equipment and equipment technology, applied in the direction of cranes, transportation and packaging, load hanging components, etc., can solve the problems of insufficient lifting capacity of bridge cranes, height restrictions of workshops, etc., achieve simple and practical structure, ensure safe construction, and install convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

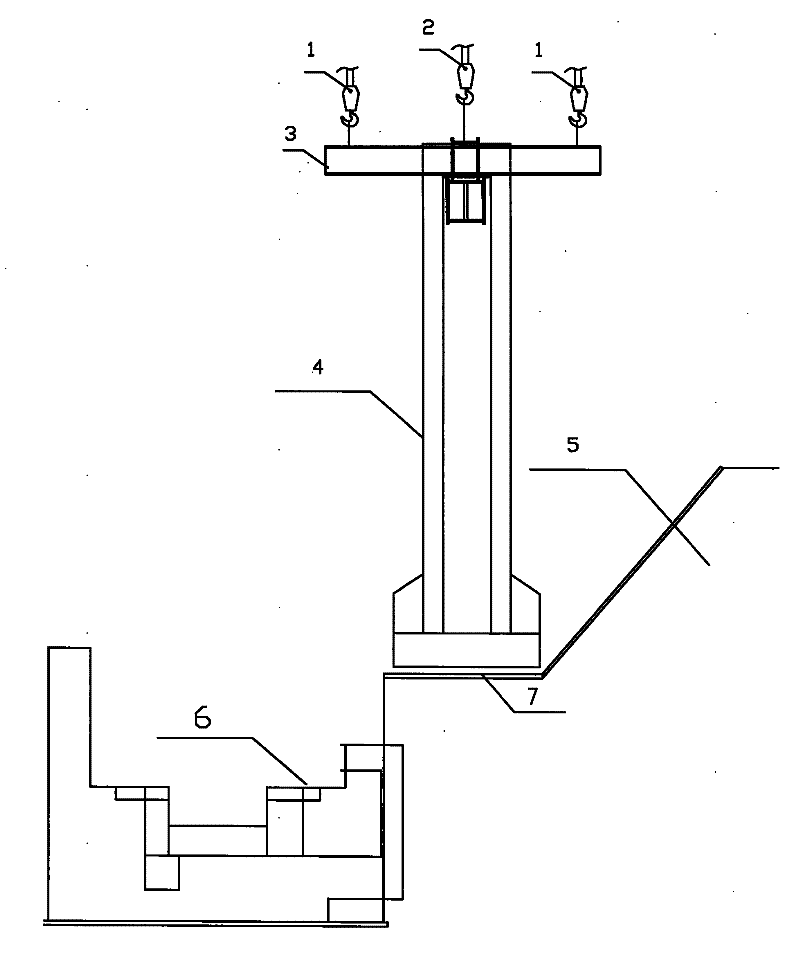

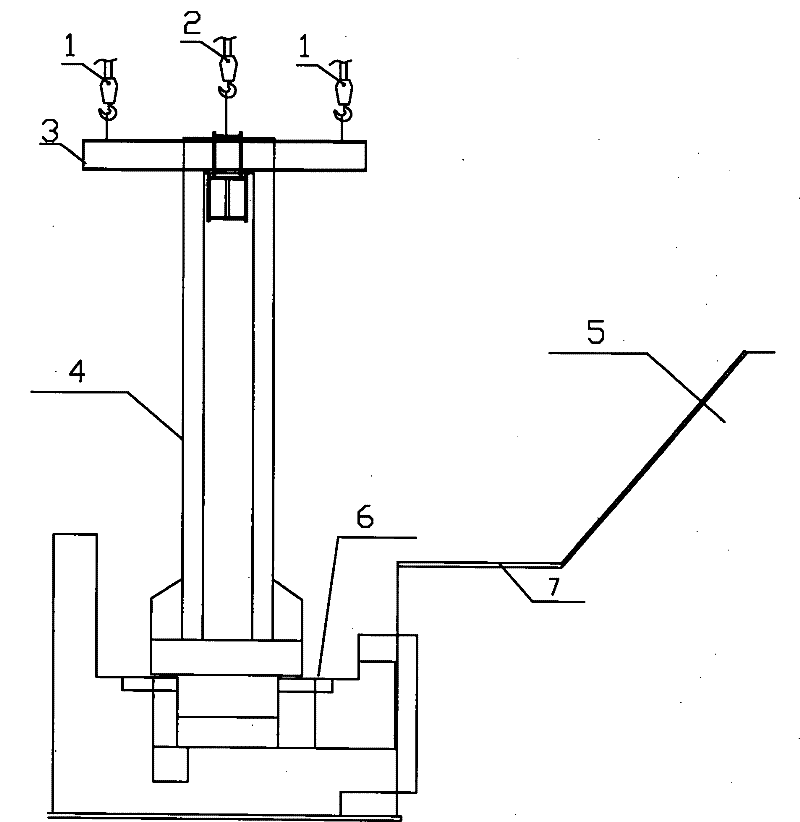

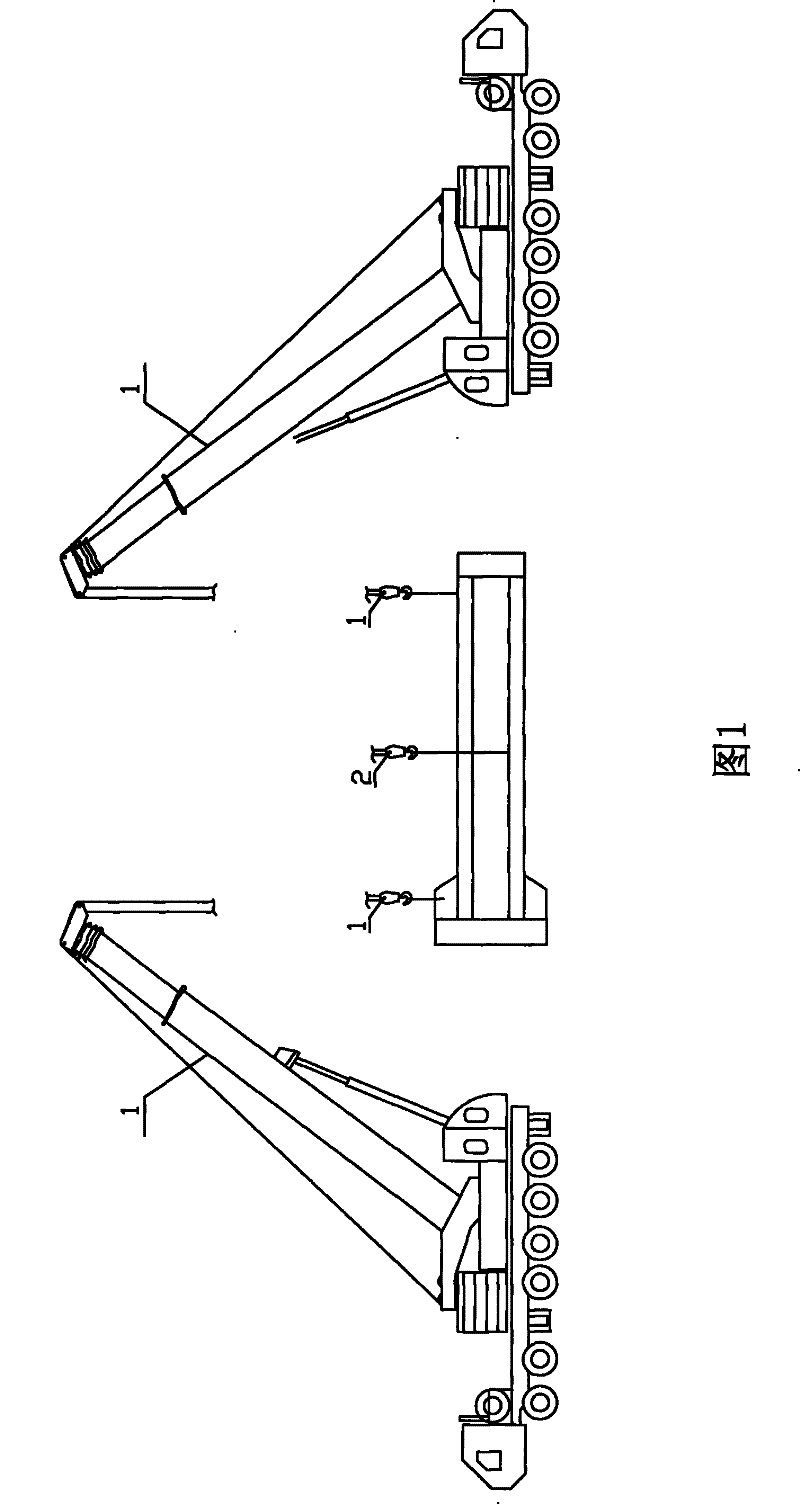

[0033] In order to better understand the present invention, the content of the invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the present invention is not limited to the following embodiments. see Figure 1 to Figure 11 :

[0034] To hoist super-high and super-heavy equipment 4 in a closed factory building, a hydraulic crane or a crawler crane of more than 200t is used according to a conventional hoisting method, but such a crane has a large volume and is limited by the site. According to the method implemented by the present invention, two hydraulic cranes 1 with less volume and a lifting capacity of 130t and a bridge crane 2 and a special spreader 3 in the workshop with a lifting capacity of 75t are used to cooperate with the lifting of super high and super heavy equipment 4. The method can solve the defects that the lifting capacity of the single-use bridge crane 2 is not enough, and the equipment is too hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com