High-speed railway orthotropic slab integral steel deck construction

A technology of orthotropic plates and high-speed railways, applied in bridges, bridge parts, bridge construction, etc., to achieve the effects of convenient manufacturing, reduced workload for later inspection and maintenance, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

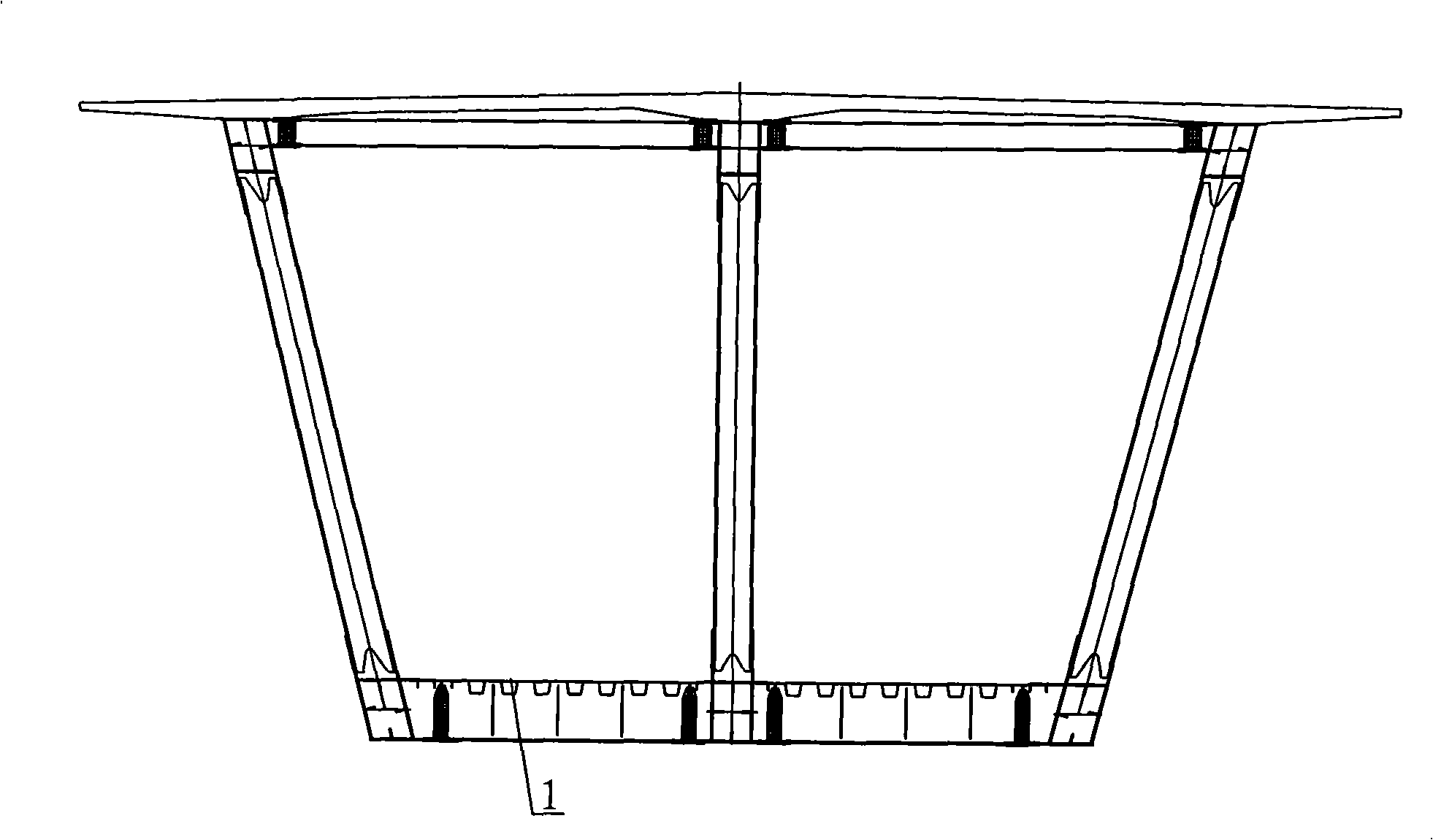

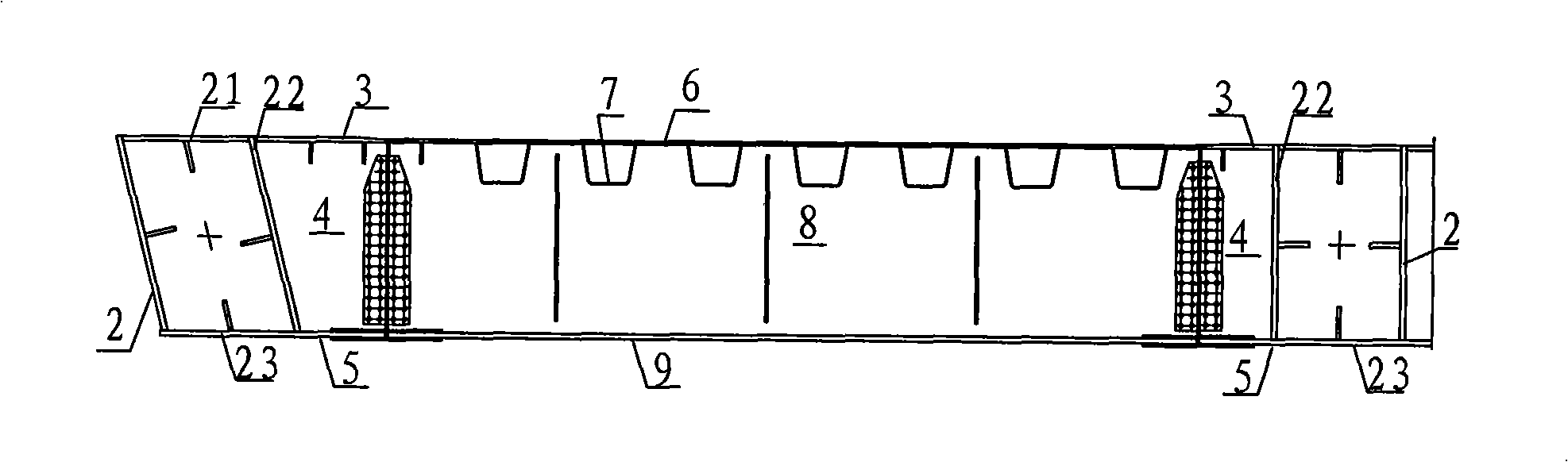

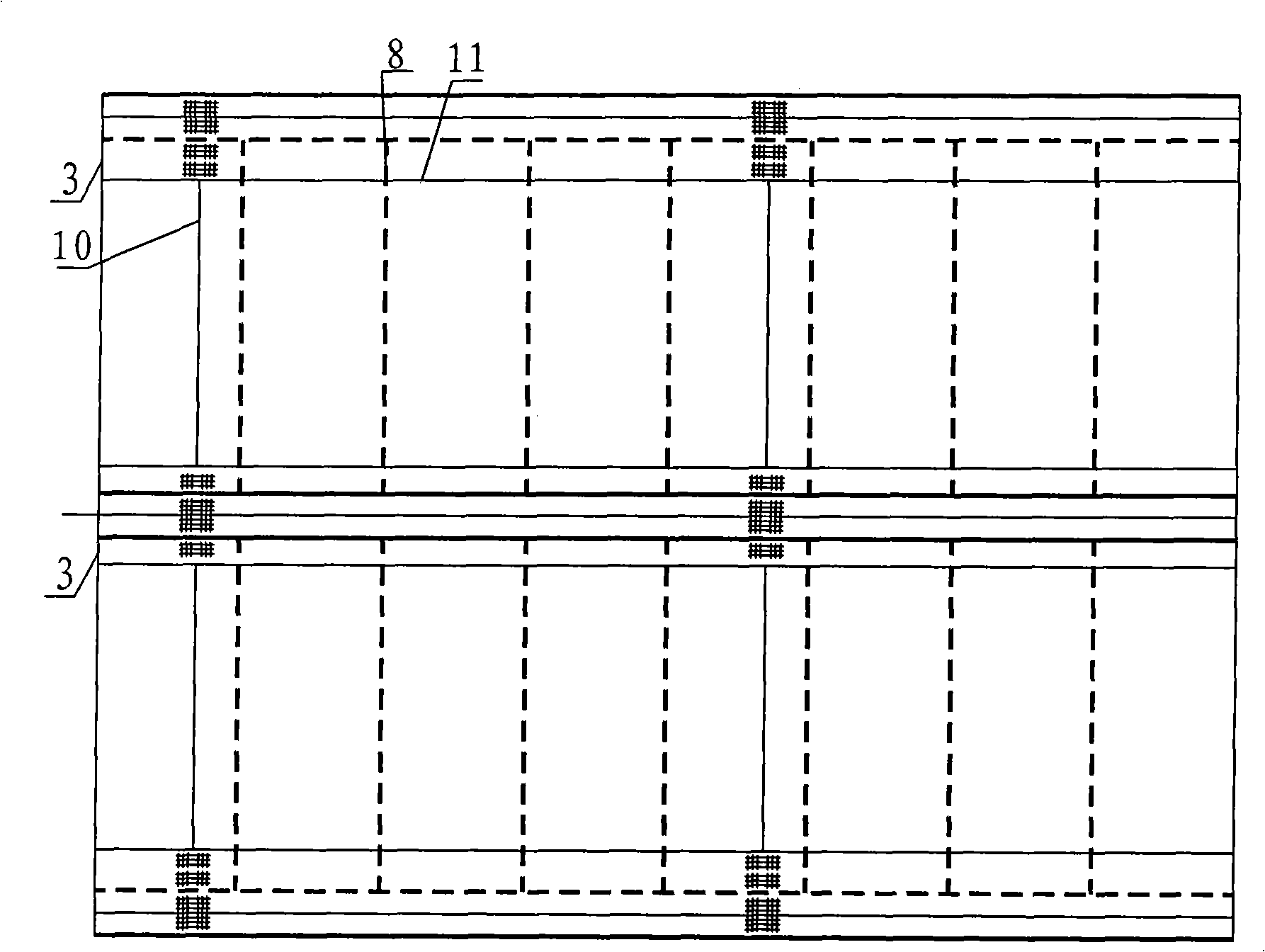

[0025] Such as Figure 1-Figure 4 As shown, it is the structure of the multi-beam non-longitudinal high-speed railway orthotropic slab integral steel deck 1 of the present invention. Transverse joints are arranged at regular intervals at the nodes of the main truss and on the members of the chord 2. The beam joints are divided into bridge deck joints 3 and beam bottom plate joints 5. The bridge deck joints 3 form a joint where the top plate 21 of the chord 2 protrudes from the vertical plate 22 of the chord 2 and is used to connect the main truss and the bridge deck 6. Top plate 21 intersects with gusset plate at the joint when stretching out vertical plate 22, and slots shall be opened at the corresponding gusset plate position to allow it to pass through, and then be welded around the arc end periphery of gusset plate. The crossbeam bottom plate joint 5 is a section joint extending the bottom plate 23 of the chord 2 out of the vertical plate, and the crossbeam web joint 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com