Fabricated fence without plug-ins and special installation tools thereof

An installation tool and an assembled technology, applied in the field of fences, can solve the problems of poor stability of the fence, easy to be eroded by wind and rain, and increase the complexity of operation, and achieve the effects of simple structure, reduced labor intensity, and reduced installation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

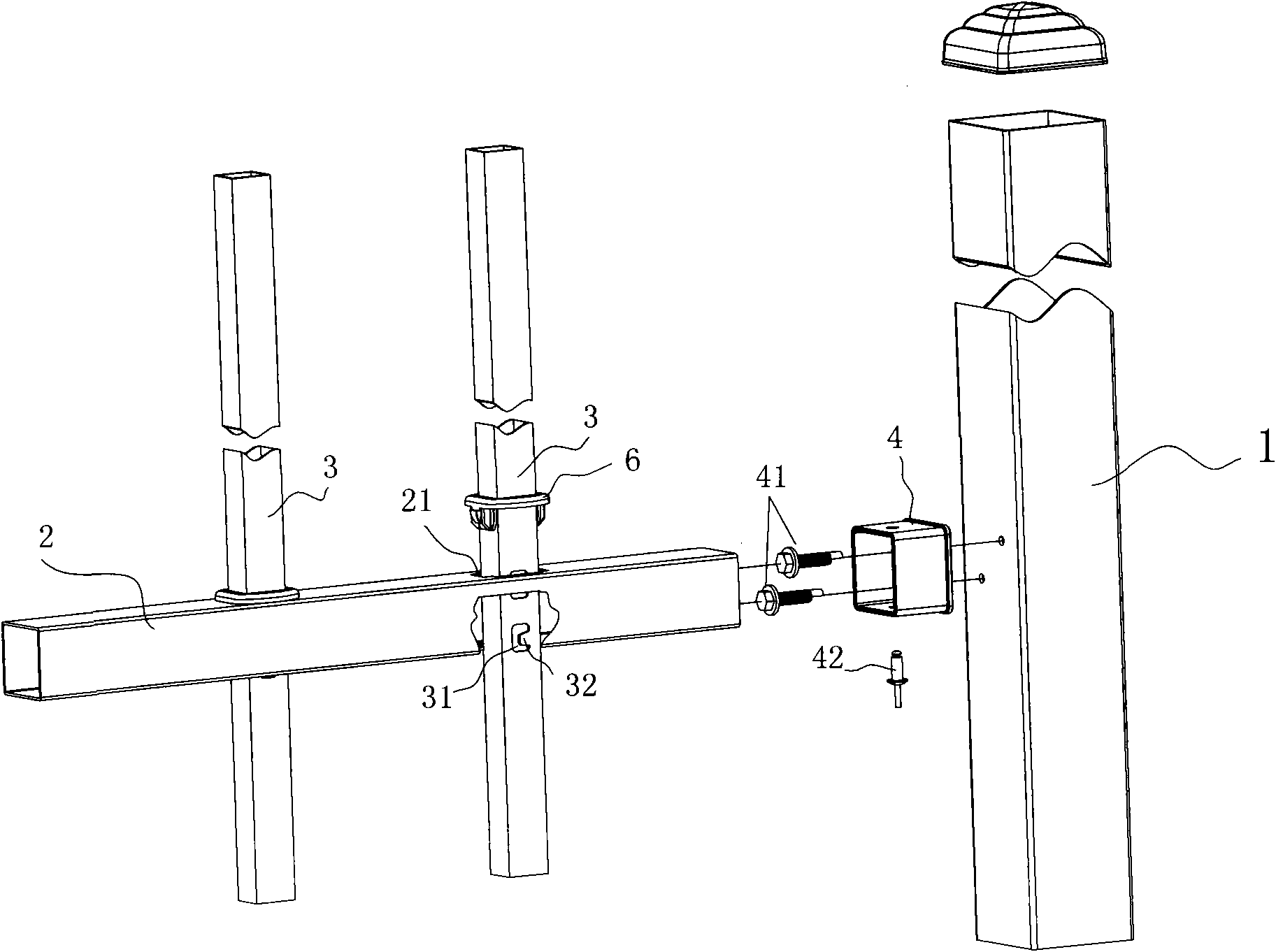

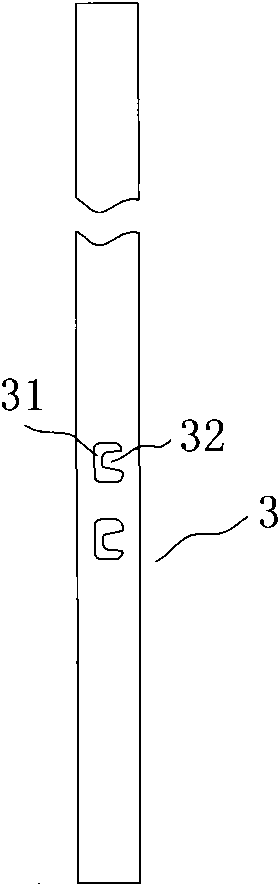

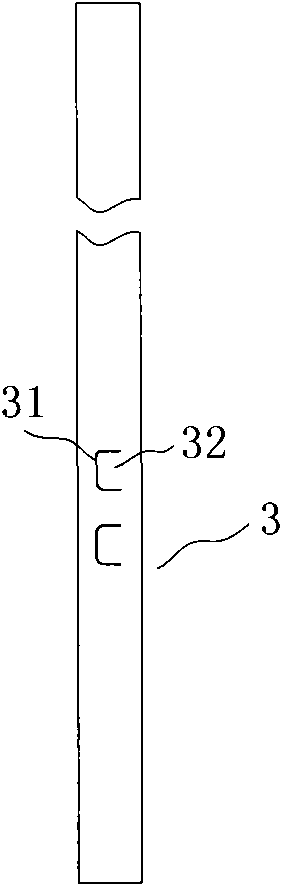

[0032] Such as figure 1 As shown, the non-plug-in assembled fence includes uprights 1 on both sides, and a cross bar 2 and a vertical bar 3 are installed in the middle of the uprights 1 on both sides. The cross bar 2 is connected to the upright post 1 through a connecting piece 4, and the connecting piece 4 is a square The fixing sleeve, the connecting piece 4 is sleeved on the outside of the cross bar 2 , and the connecting piece 4 has a mounting hole and a fixing pin 42 . There are a plurality of vertical rod installation holes 21 on the cross bar 2 , and a plurality of vertical rods 3 penetrate into the plurality of installation holes on the cross bar 2 in turn. The vertical bar 3 is covered with a protective ring 6, which is arranged on the upper surface of the vertical bar mounting hole 21 on the horizontal bar 2 to play the role of waterproof, cushioning and decorati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com