Water-control type water-return secondary stop safety protector for hydraulic compressor

A technology of safety protection device and hydraulic press, which is applied in engineering safety devices, mechanical equipment, etc., can solve the problems of hidden dangers, endangering the life safety of people between the main slider and the side blanking slider, and gushing out, so as to solve the problem of safety. hidden dangers and the effect of increasing the reliability of safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

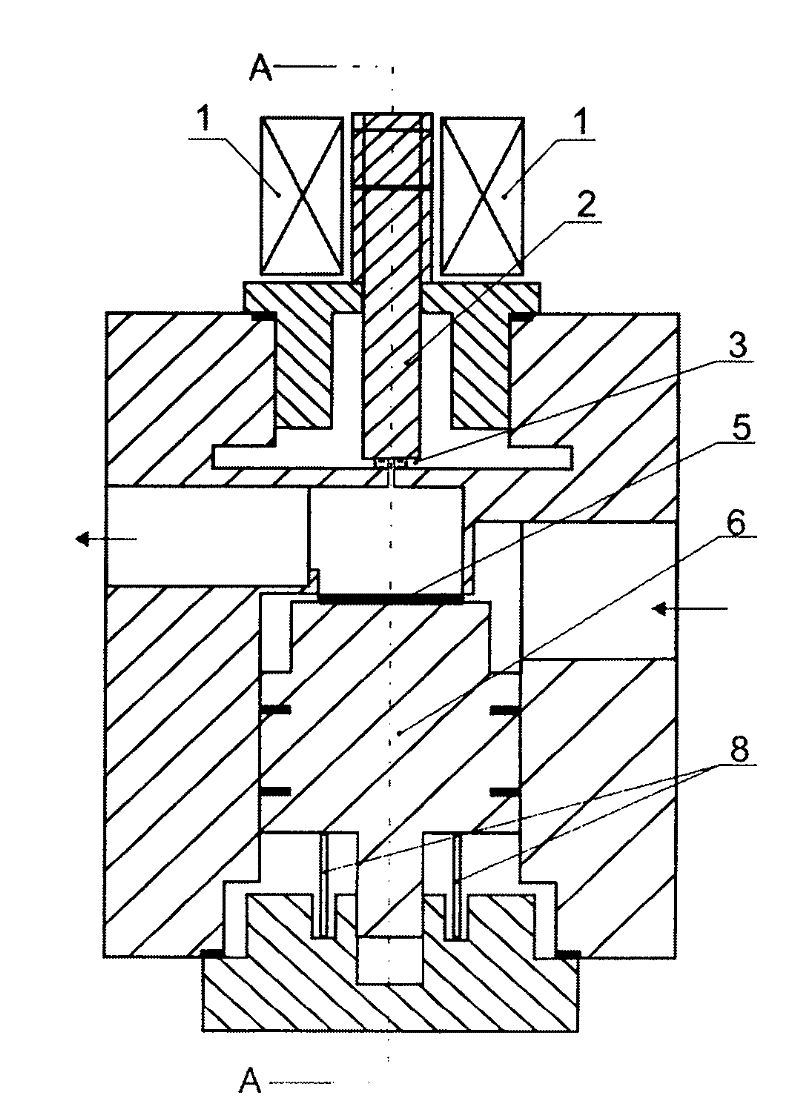

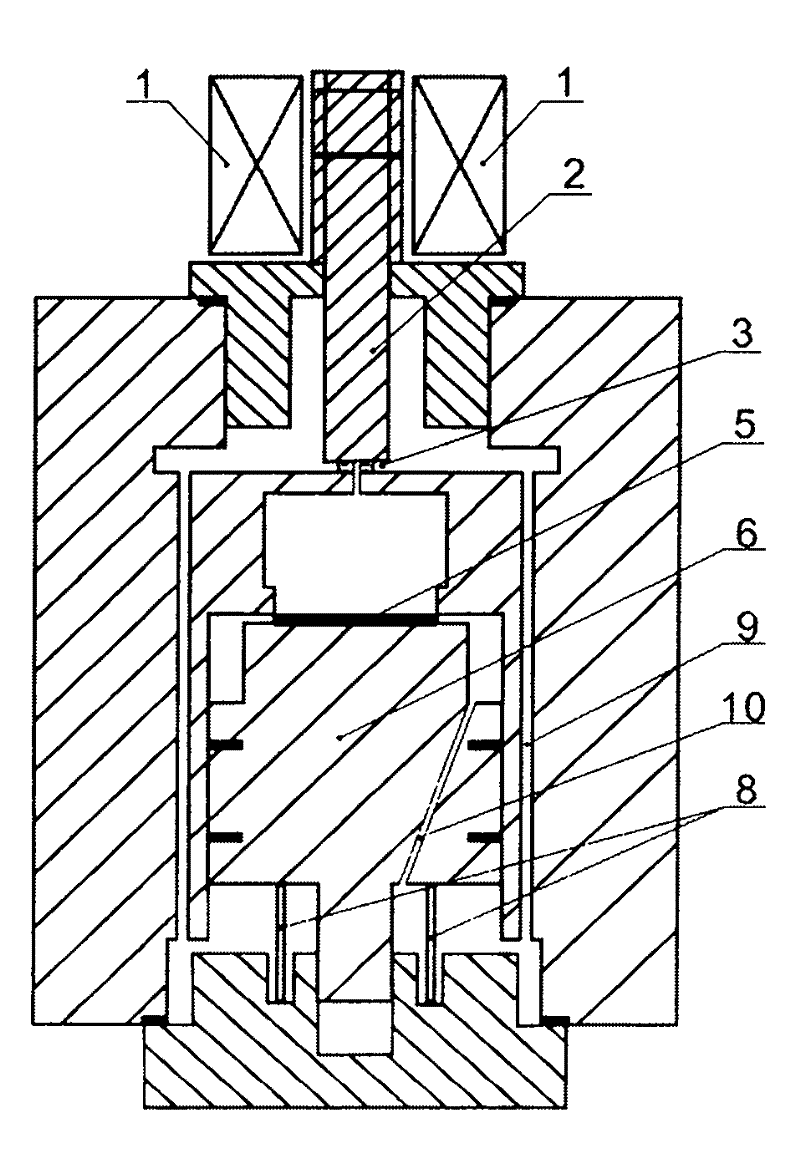

[0018] Below in conjunction with accompanying drawing, the present invention will be further specifically described:

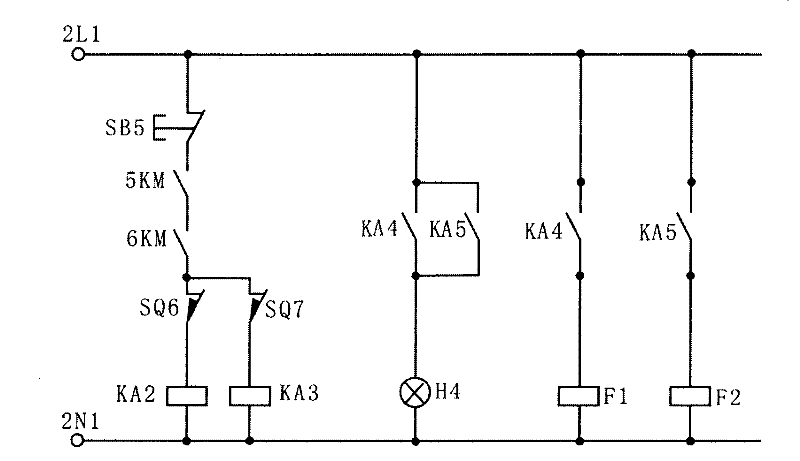

[0019]In the present invention, a main electromagnetic valve F1 is installed in series on the return water pipe of the main distributor of the hydraulic press, and a flange electromagnetic valve F2 is installed in series on the return water pipe of the edge distributor of the hydraulic press. The main electromagnetic valve F1 and The blanking solenoid valves F2 are all high-voltage solenoid valves, and the high-voltage solenoid valves are in the state of opening the waterway when the power is turned on, and are in the state of cutting off the waterway when the power is off; the power input terminal of the main solenoid valve F1 is connected to the corresponding first intermediate relay The normally open switch KA4 of KA2 is connected in series and then connected to the power line, and the power input end of the pressure solenoid valve F2 is connected in series ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com