An ultra-thin vehicle-mounted magnetic levitation flywheel battery and its working method

A flywheel battery and magnetic levitation technology, applied in the direction of motors, electric components, electric vehicles, etc., can solve the problems of limited application and promotion, reduction of air gap magnetic flux, poor sound insulation effect, etc., achieve high energy storage density, increase speed, Reduces the effect of the gyroscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

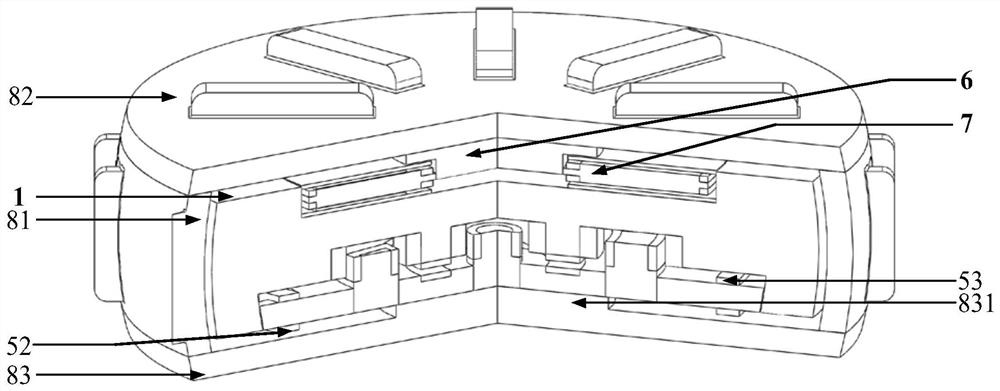

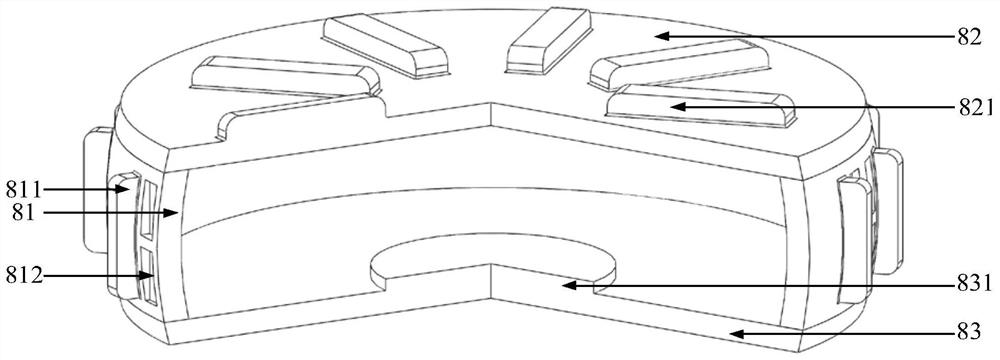

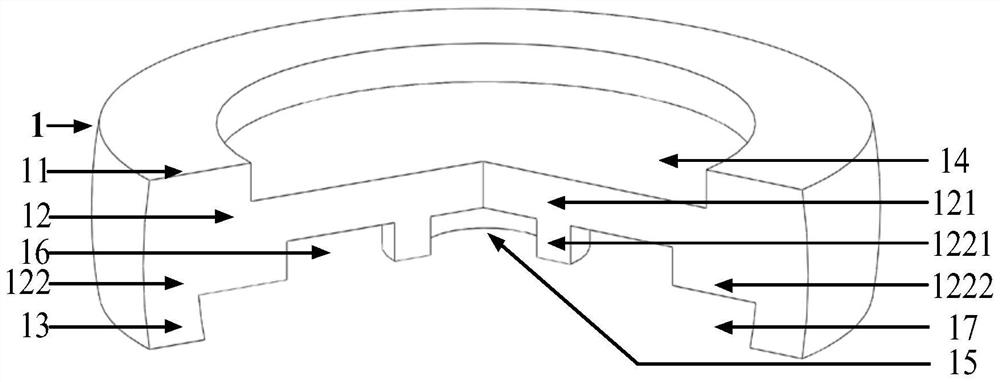

[0049] see figure 1 and combine figure 2 As shown, the outermost part of the present invention is a shell, which is composed of a shell body 81, an upper end cover 82 and a lower end cover 83 sealed and connected, and its material is aluminum foam. The upper end of the shell body 81 is tightly and fixedly connected to the upper end cover 82, and the lower end of the shell body 81 is tightly and fixedly connected to the lower end cover 83. The shell body 81, the upper end cover 82 and the lower end cover 83 form a sealed vacuum chamber to reduce air friction loss. The shell body 81 is a hollow partial spherical shell, with cooling fins 811 and cooling grooves 812 arranged on the outer peripheral surface. It is a square groove, grooved outward along the diameter direction, and every four cooling fins 811 arranged in a square array form a group. Along the circumferential direction, two cooling grooves 812 are symmetrically arranged on both sides of the four cooling fins 811 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com