Thermal resistance simulation and calibration system for device ageing screening lathe

A thermal resistance simulation and device aging technology, which is applied in the direction of instruments, measuring electricity, and measuring electrical variables, etc., can solve the problems of affecting the accuracy of temperature detection and reducing the accuracy of devices, and achieve the effect of improving temperature detection accuracy and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

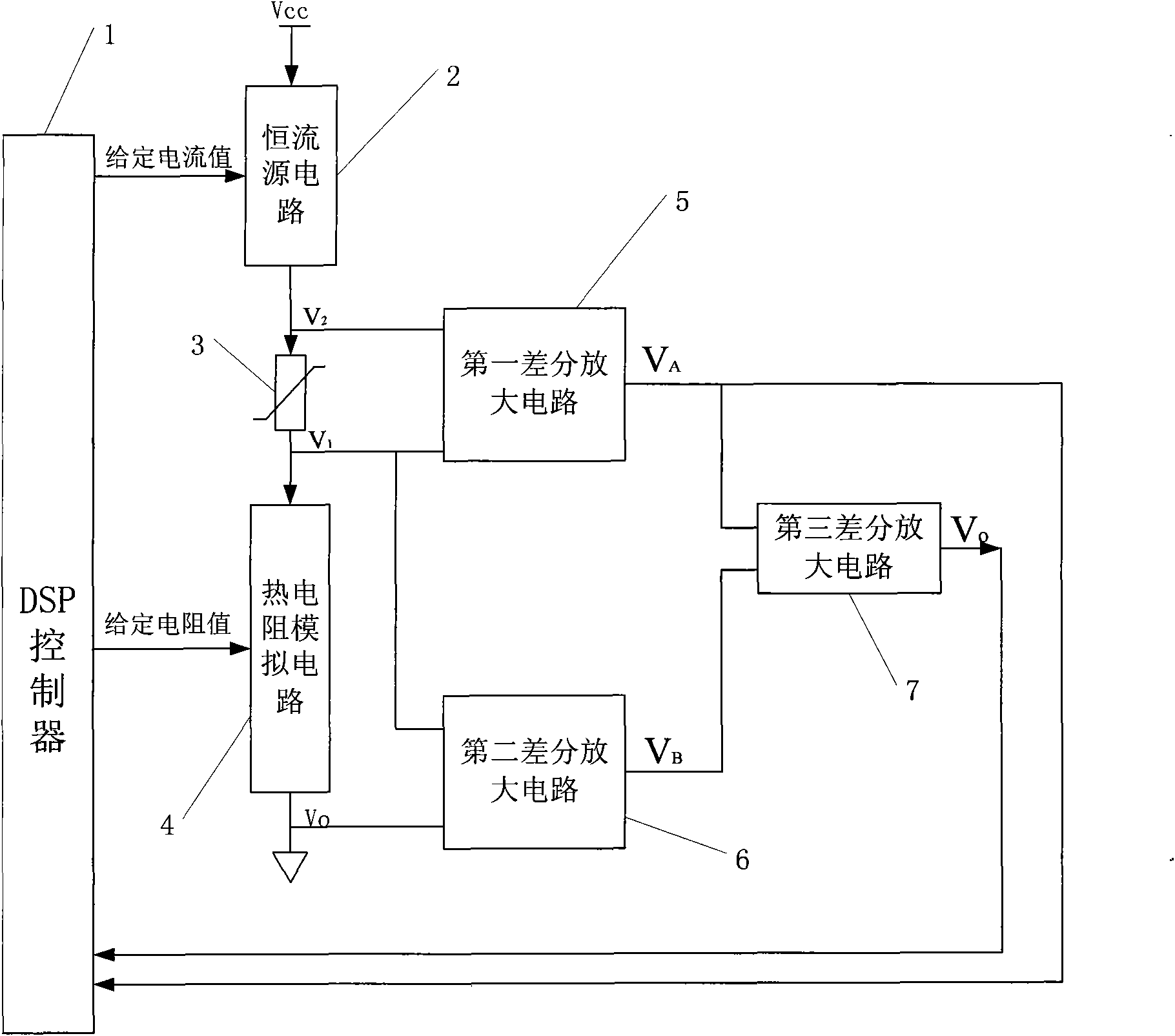

[0019] see figure 1 , the figure shows the thermal resistance simulation calibration system for the device aging screening vehicle of the present invention, which includes a DSP controller 1, a constant current source circuit 2, a thermal resistance 3, a thermal resistance simulation circuit 4, and a first differential amplifier circuit 5. The second differential amplifier circuit 6 and the third differential amplifier circuit 7, the thermal resistor 3 and the thermal resistor analog circuit 4 are connected in series with the constant current source circuit 2, and the currents flowing through the two are exactly the same, wherein:

[0020] The constant current source circuit 2 obtains electric energy from the power supply Vcc, and generates a corresponding constant current flowing through the thermal resistance 3 and the thermal resistance analog circuit 1 according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com