Mandrel rod damping structure

A component and shaft hole technology, applied in the structural field of restraining shaft rod vibration, can solve problems such as unsolved vibration, and achieve the effect of good position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of two preferred embodiments with reference to the accompanying drawings.

[0027] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same reference numerals.

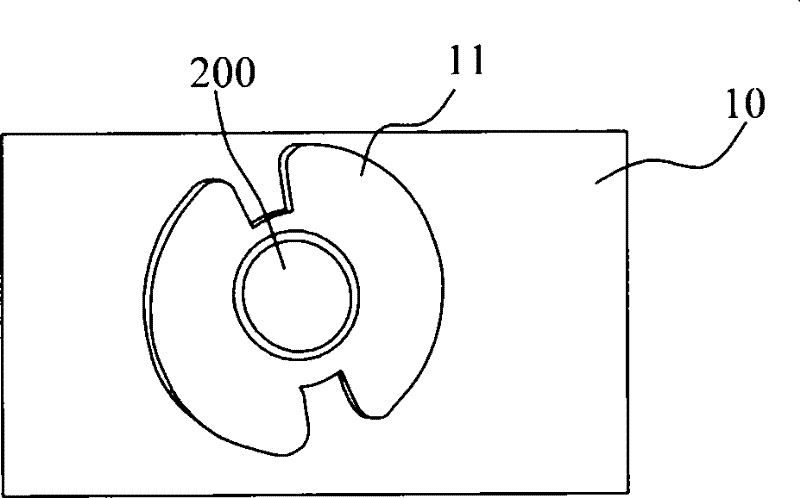

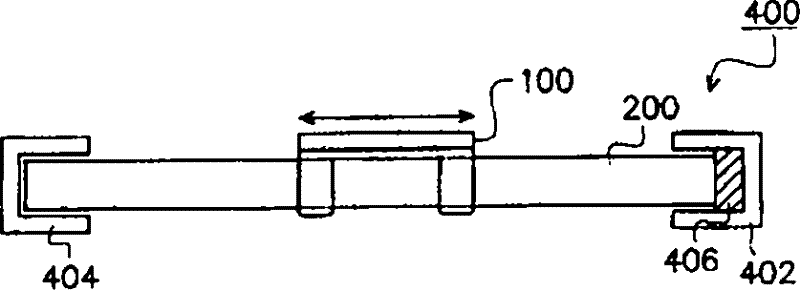

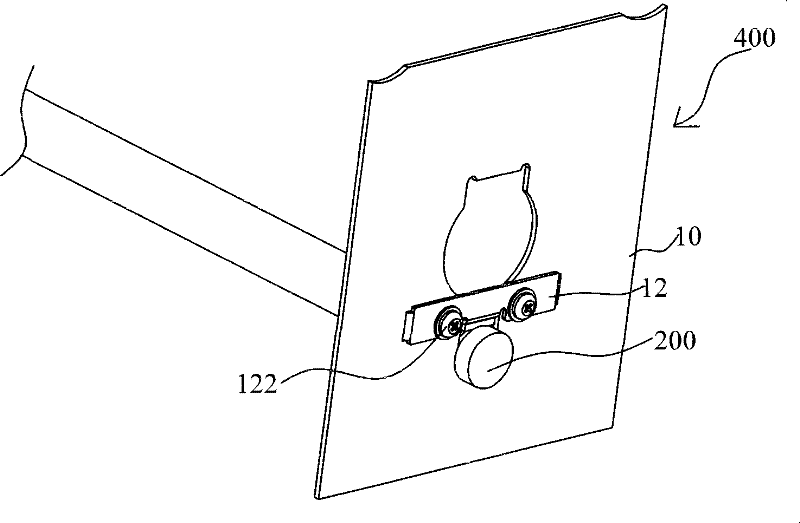

[0028] Figure 2a It is an installation diagram of a preferred embodiment of the present invention. Such as Figure 2a As shown, a preferred embodiment of the present invention discloses a shaft damping structure 400 , the shaft damping structure 400 mainly includes a housing 10 and a pressing member 12 . Wherein, the pressing member 12 is connected to the housing 10 through screws or rivets, and is forced to fix the shaft rod 200 installed on the housing 10 .

[0029] It should be noted that the screw connection is taken as an example below, and its replacemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com