Position-pressure composite control method for electro-hydraulic servo system with double actuators in series

An electro-hydraulic servo system and composite control technology, which can be used in fluid pressure actuation system components, fluid pressure actuation system testing, servo motors, etc., and can solve problems such as lack of control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

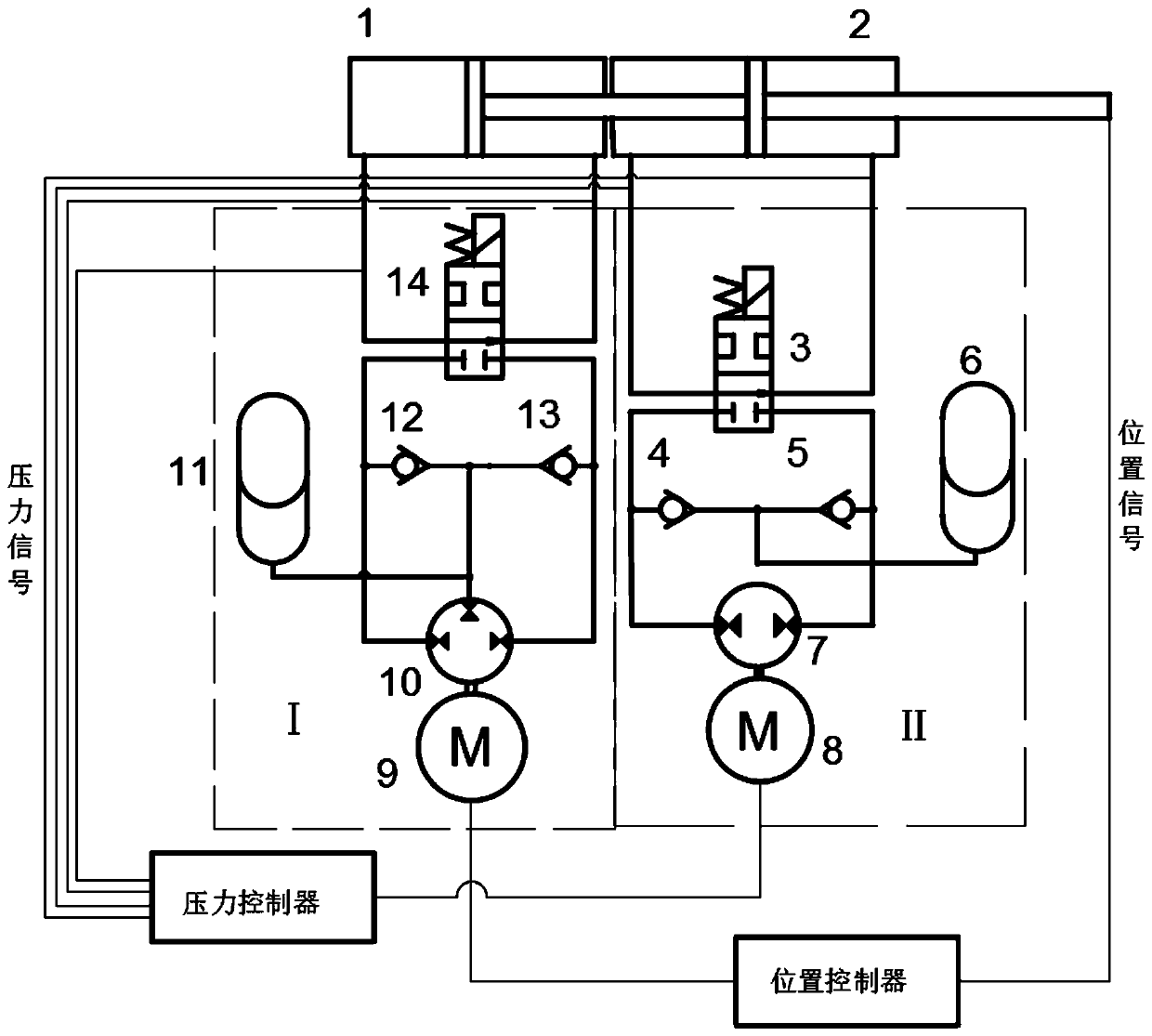

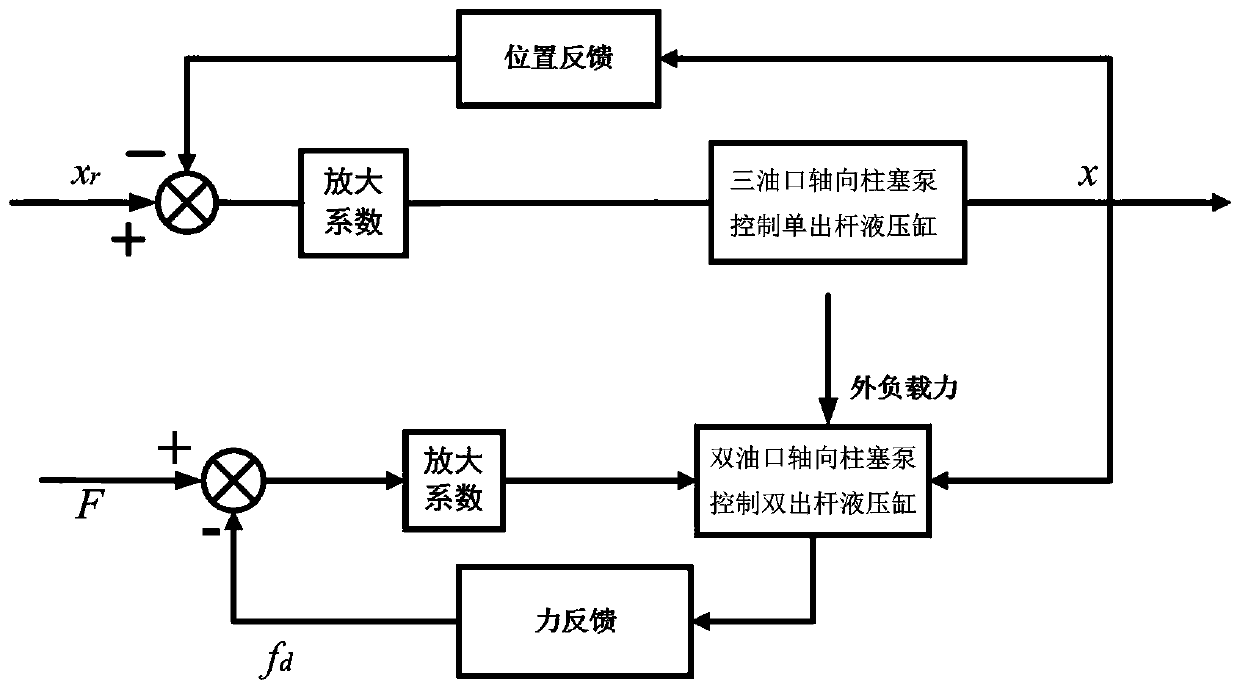

[0022] A position and pressure composite control method for an electro-hydraulic servo system with double actuators in series, wherein the electro-hydraulic servo system with double actuators in series includes a series hydraulic cylinder formed by connecting a double-rod hydraulic cylinder 2 and a single-rod hydraulic cylinder 1 in series. Displacement sensors are installed on the actuators of the series hydraulic cylinders, and pressure sensors are installed on the connecting oil passages of each cavity, such as figure 1 As shown, the control method of the series hydraulic cylinder includes the following steps:

[0023] ① Control the motor A9 to start, and the two-position four-way electromagnetic reversing valve A14 is energized to drive the three-port axial plunger pump 10 to open to supply liquid to the single-rod hydraulic cylinder 1, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com