Positioning fixture for pile foundation reinforcement cage

A pile foundation reinforcement cage and positioning fixture technology, applied in sheet pile walls, infrastructure engineering, structural elements, etc., can solve the problems of collision, increase the thickness of hole slag, and the thickness of steel protection layer is different, so as to avoid The effect of damage, sufficient strength, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In this embodiment, a positioning fixture for a reinforcement cage of a pile foundation includes a fence that can be arranged in the pile hole, and a through hole for passing the reinforcement cage is arranged in the fence.

[0018] During construction, install the fence at the entrance of the pile hole, hoist the reinforcement cage and align the reinforcement cage with the through hole of the fence, then put down the reinforcement cage, and use the fence to limit and guide the reinforcement cage, so that Avoid contact between the reinforcement cage and the inner wall of the pile hole, and limit the reinforcement cage to the range covered by the through hole, so that the distance between the reinforcement cage and the inner wall of the pile hole remains constant, which is conducive to making the thickness of the concrete protective layer uniform and reach the design target. required requirements.

Embodiment 2

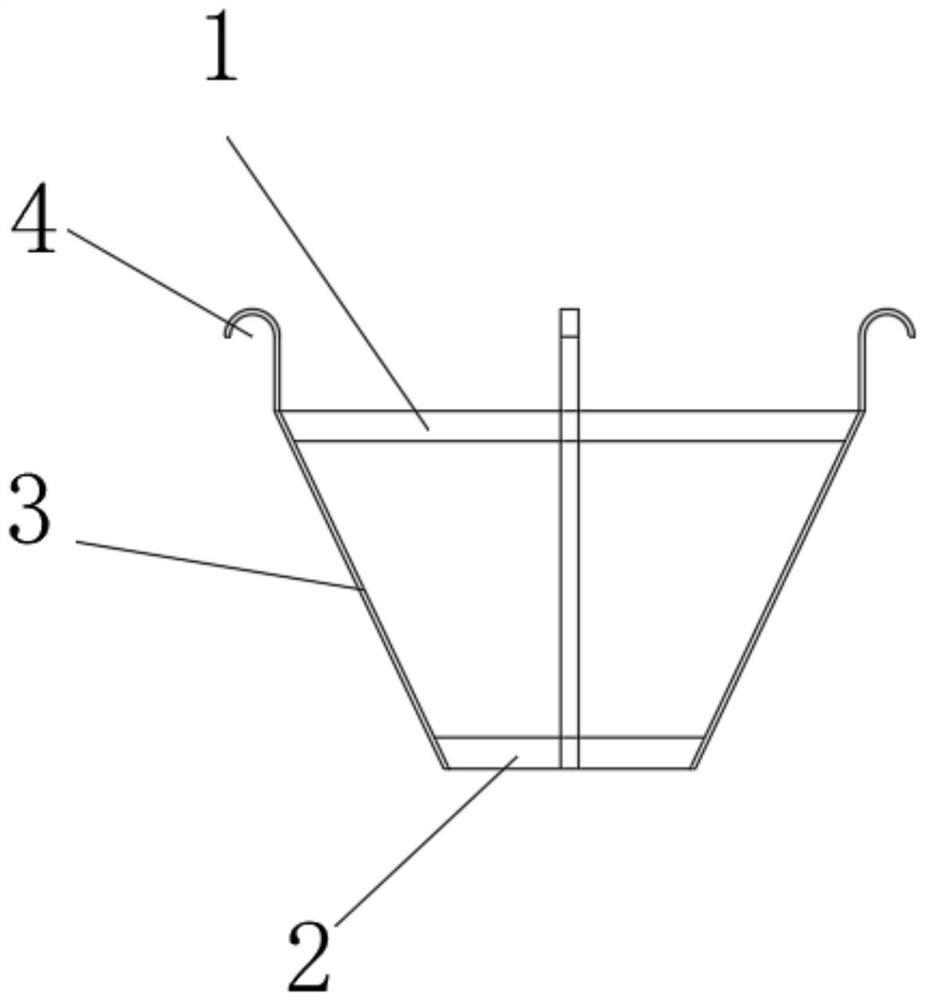

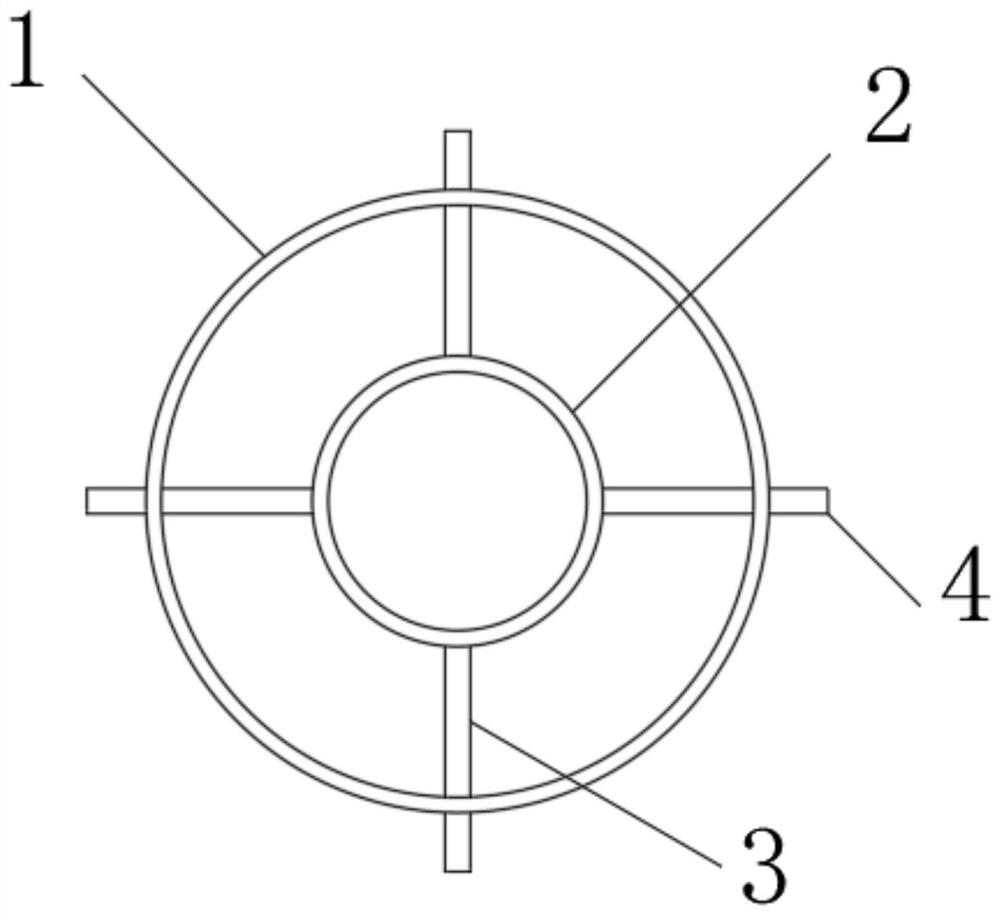

[0020] Such as figure 1 , figure 2 As shown, on the basis of the above embodiments, in this embodiment, the fence includes A limit ring 1 and B limit ring 2 arranged below A limit ring 1, A limit ring 1 and B limit ring A connection structure is provided between the bit rings 2 . A limit ring 1 and B limit ring 2 are used to guide and limit the reinforcement cage. A limit ring 1, B limit ring 2 and the connection structure form a frame structure, which can reduce the weight of the fence. Thereby, the pressure of the fence on the pile hole is reduced, and the pressure damage at the entrance of the pile hole is avoided.

[0021] In this embodiment, the diameter of the A limiting ring 1 is larger than the diameter of the B limiting ring 2, and the A limiting ring 1 and the B limiting ring 2 are coaxial. In this way, the maximum outer diameter of the A limiting ring 1 can be matched with the inner diameter of the pile hole, and the gap between the A limiting ring 1 and the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com