Manufacturing method of trapezoidal air filtering belt

A technology of air filtration and manufacturing methods, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of inability to reduce costs, damage of machine parts, complex structure of air filters, etc., and achieve improved resistance to external pull Ability, the effect of rapid combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

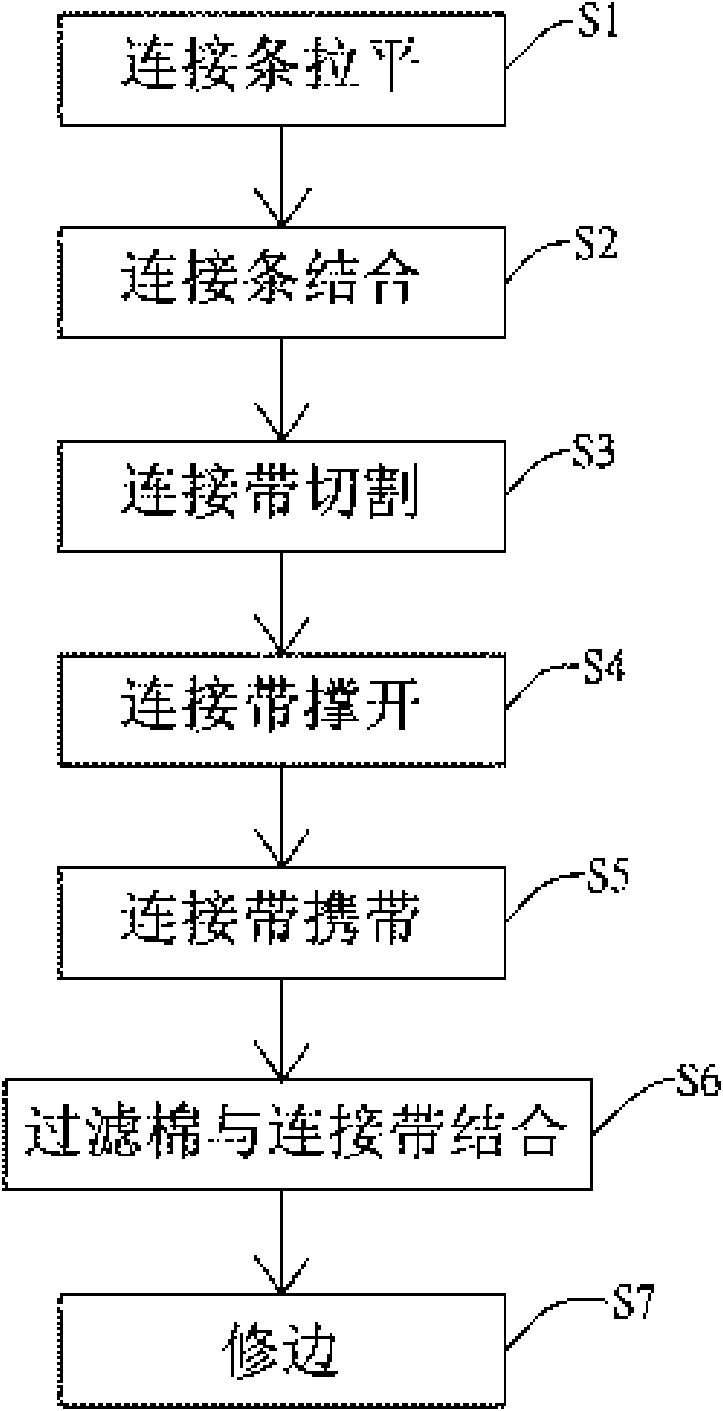

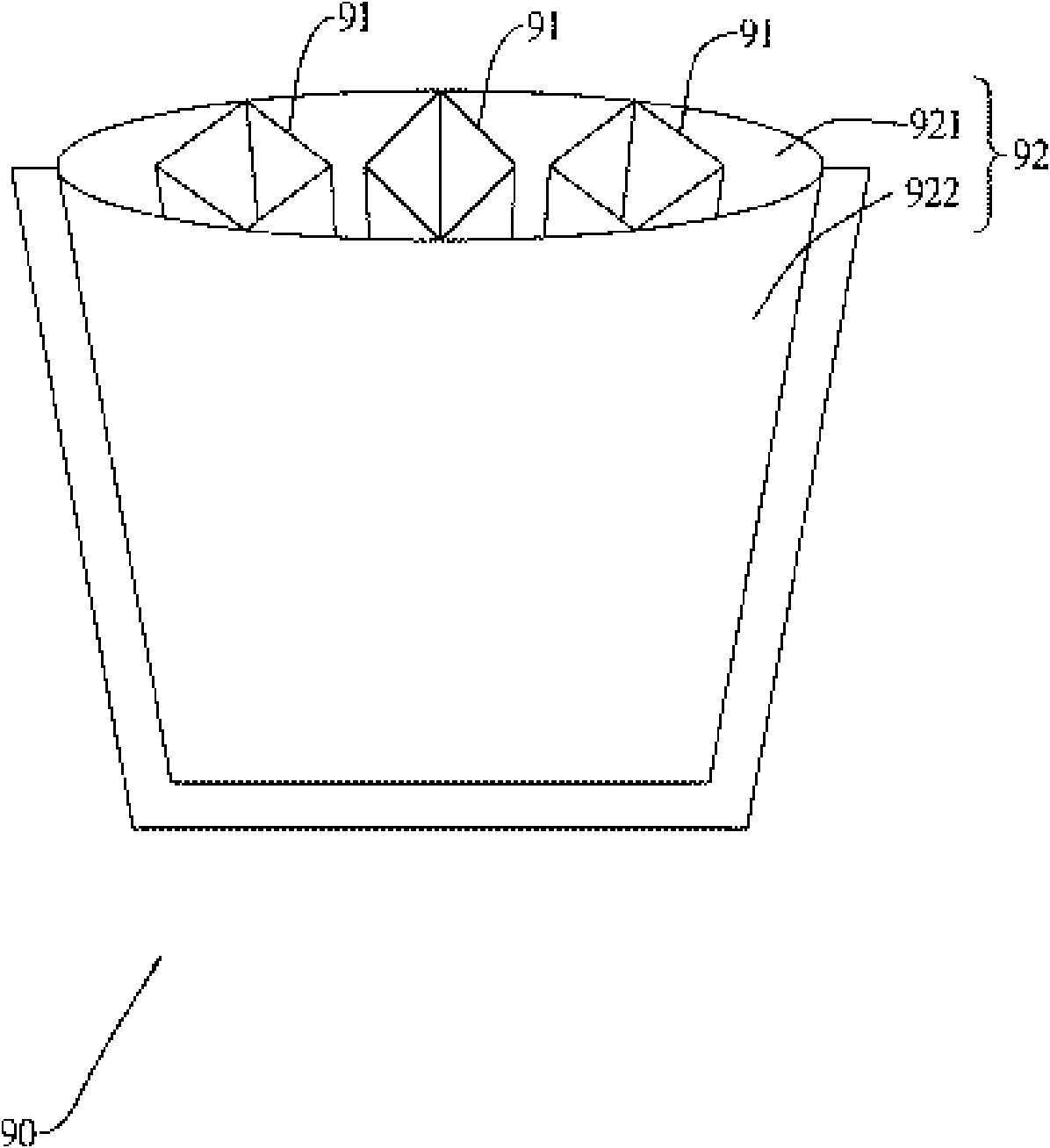

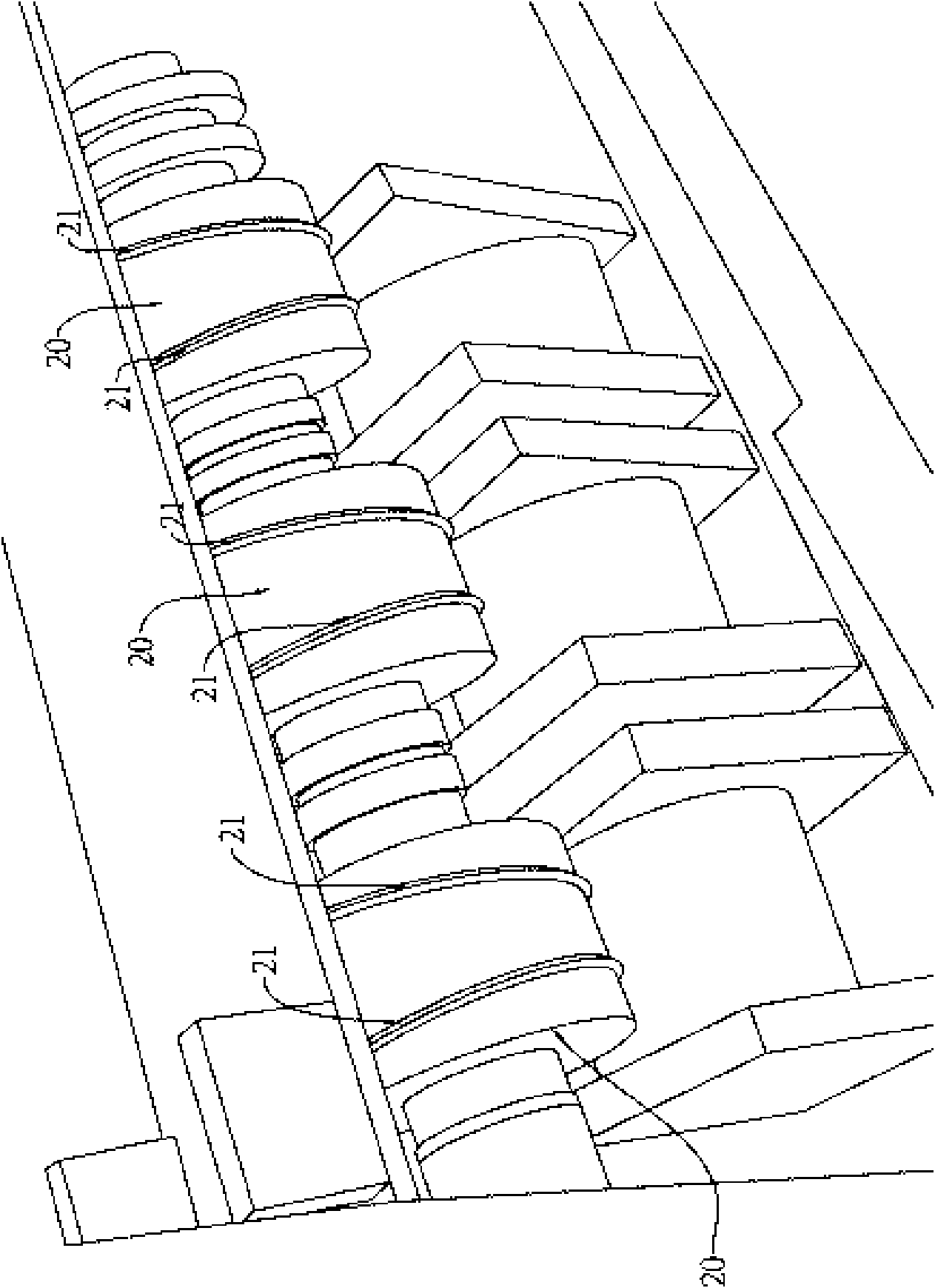

[0047] see figure 1 and figure 2 As shown, the present invention is a manufacturing method of a trapezoidal filter belt 90, which is achieved by automated machinery. The trapezoidal filter belt includes at least one connecting belt 91 and a filter cotton 92, and the filter cotton 92 includes an upper filter cotton 921 and the next filter cotton 922, and the connecting strip 91 is formed by connecting at least two connecting strips, and the manufacturing method of the connecting strip of the present invention comprises a connecting strip leveling step S1, a connecting strip combining step S2, a connecting strip cutting Step S3, step S4 of stretching a connection belt, step S5 of carrying a connection belt, step S6 of combining filter cotton with a connection belt, and a step S7 of trimming, wherein, the step S1 of leveling the connection strip is to flatten and stretch the connection strip, In order to facilitate subsequent actions, the connecting strip combining step S2 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com