Methane synthesis reactor

A methane synthesis and reactor technology, applied in the field of methane synthesis reactors, can solve the problems of lowering the temperature of the catalyst bed of the adiabatic reactor, increasing the power of the external circulation compressor, selecting equipment materials and cost burden, etc., and improving the heat extraction method. , The effect of investment cost reduction and operation safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

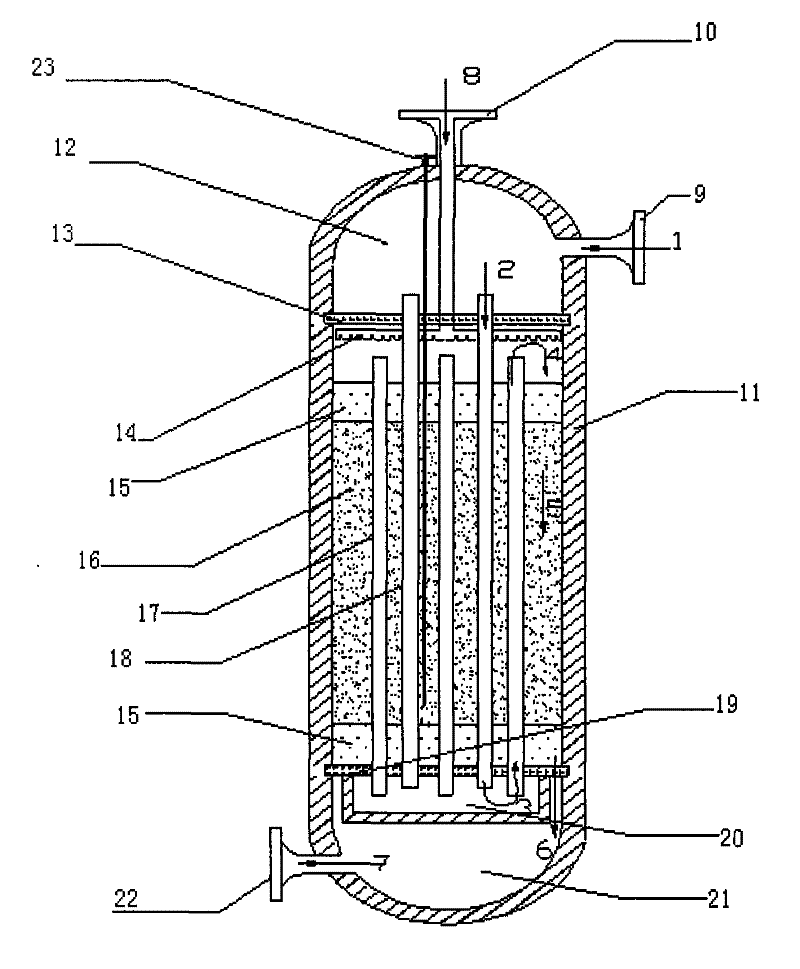

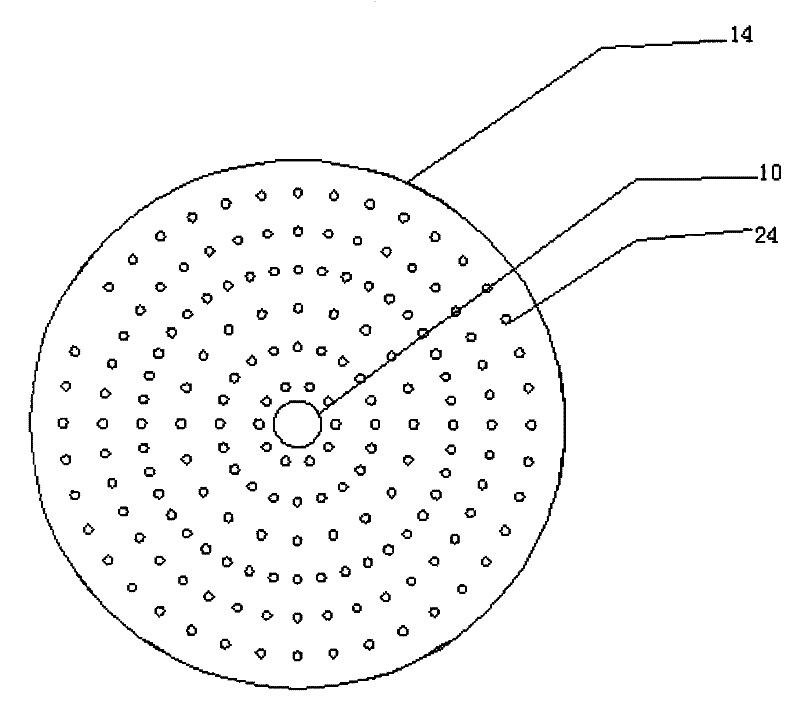

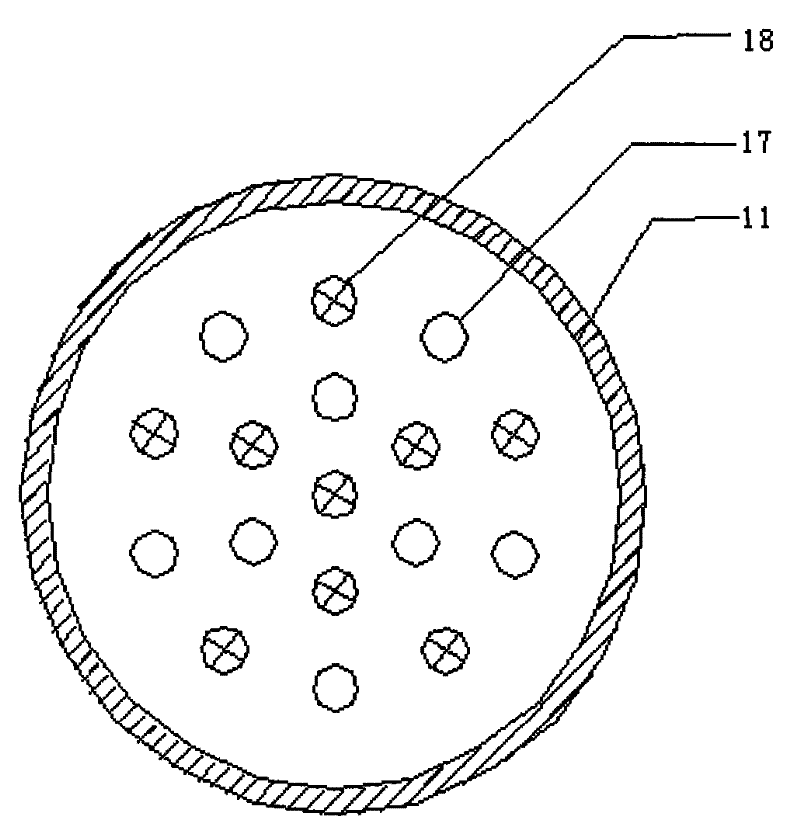

[0023] Such as figure 1 , figure 2 with image 3 As shown, the reactor includes a raw material inlet 9 on the top of the shell, a cooling gas inlet 10 on the top of the shell, a shell 11, a buffer chamber 12 formed by the seal on the top of the reactor and the upper supporting plate, and an upper supporting plate 13. , cold shock gas distributor 14, catalyst upper and lower packing layers 15, catalyst bed 16, countercurrent heat exchange tube 17 and downstream heat exchange tube 18, catalyst lower bearing plate 19, communication air chamber 20 for updraft and downdraft, catalyst The support plate and the bottom of the reactor are sealed to form a buffer chamber 21, a product outlet 22 at the bottom of the shell, and a thermocouple installation port 23. figure 2 Shown is the distribution of the gas outlets 24 of the cold shock gas distributor 14 . A certain number of countercurrent heat exchange tubes 17 and downstream heat exchange tubes 18 are distributed in the catalyst...

Embodiment 2

[0029] Using the same methane synthesis reactor as in Example 1, the difference is: feed gas does not need product gas circulation, CO 10% in the synthesis gas, CO 2 36.5%, H 250.8%, other gases 2.7%, the cross-sectional area ratio of the downstream heat exchange tube 18 and the countercurrent heat exchange tube 17 is 0.73 / 1; The proportion of the body cross-sectional area is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com