Articulated field operation vehicle chassis

A field operation, articulated technology, applied to vehicle components, traction connectors, hydraulic steering gear, etc., can solve the problems of off-road performance, traction capacity and mobility, etc., to improve off-road performance and traction performance, strong terrain Effect of adaptability, high driving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

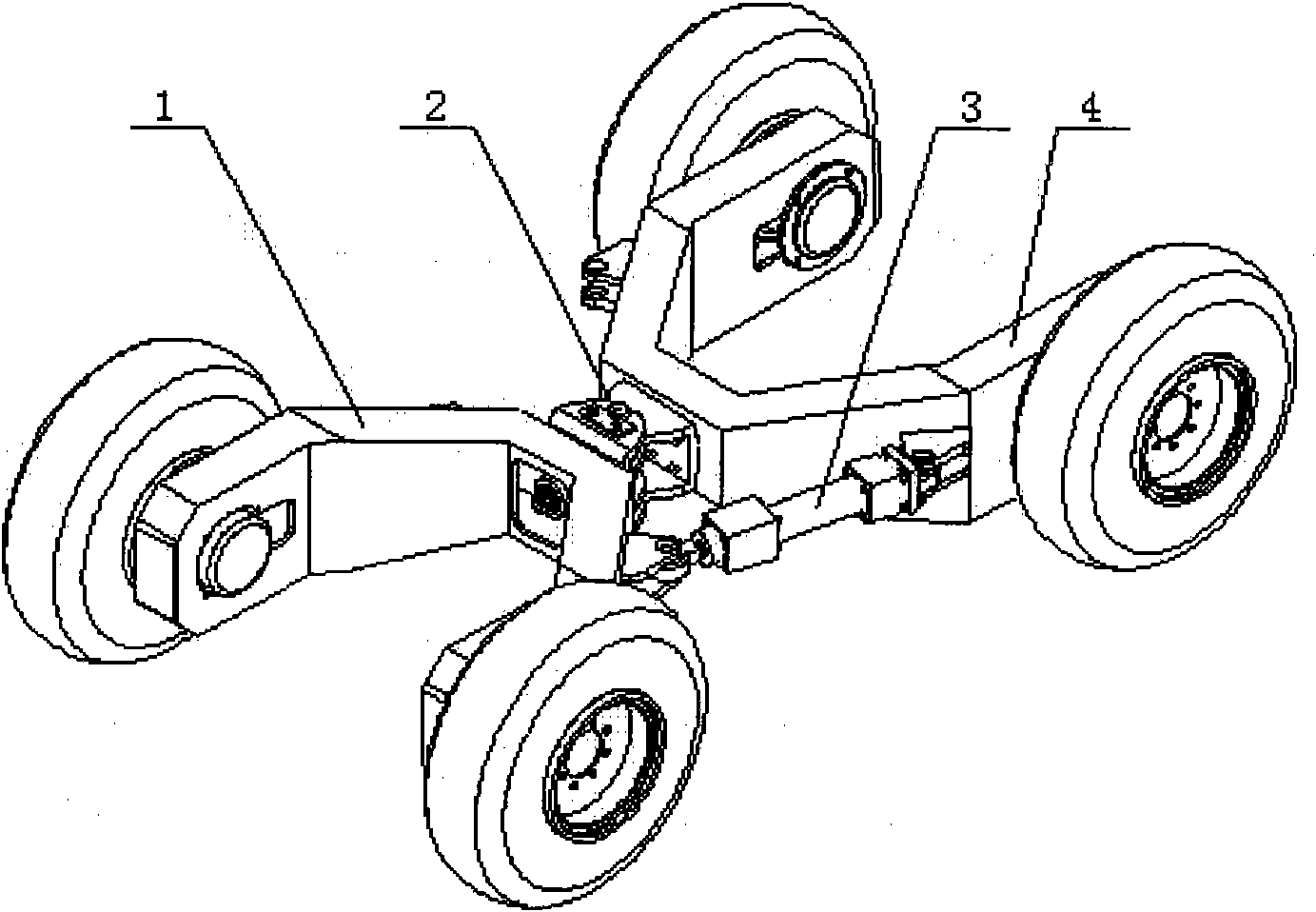

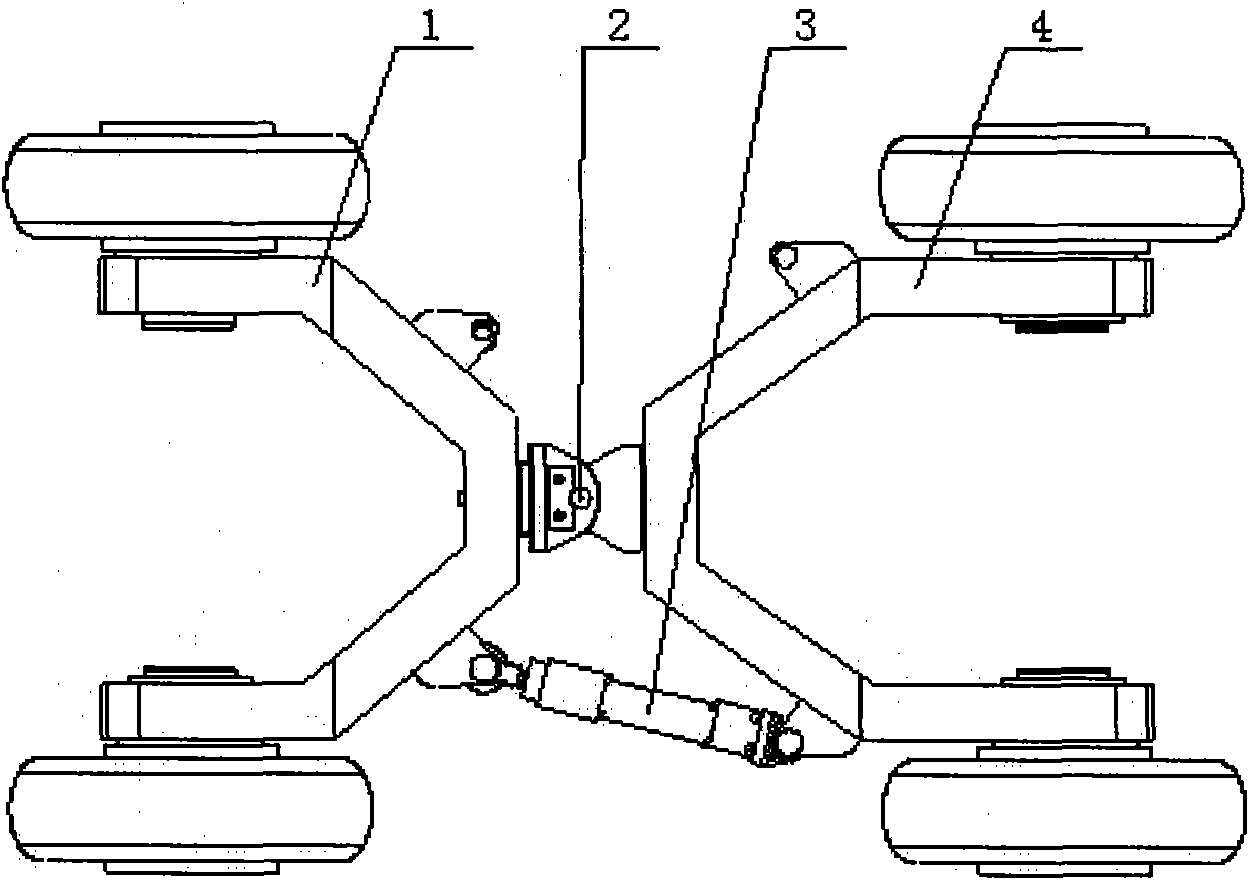

[0024] Such as figure 1 as shown in figure 1 , 2 As shown, Embodiment 1 includes: a front frame 1, a two-degree-of-freedom hinge mechanism 2, a hydraulic steering mechanism 3, and a rear frame 4. The front frame 1 is connected to the rear vehicle through a two-degree-of-freedom hinge mechanism 2 and a hydraulic steering mechanism 3. The frame 4, the two free hinge mechanisms 2 and the hydraulic steering mechanism 3 realize the longitudinal swing along the direction of the frame and the lateral rotation along the vertical axis between the front frame 1 and the rear frame 4, which improves the steering of the vehicle when driving off-road. The ability and the grounding performance of the tires meet the requirements of wild off-road driving.

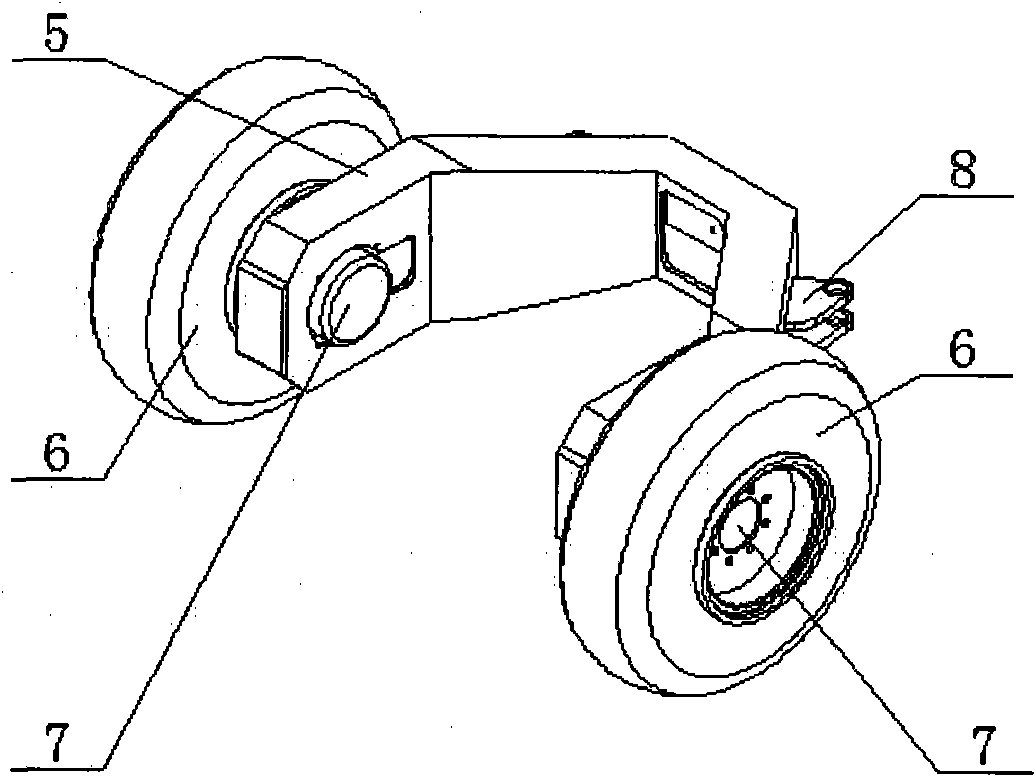

[0025] Such as image 3 As shown, the front frame 1 of embodiment 1 is made up of front frame steel structure 5, two front frame wheels 6, two sets of wheel side hydraulic drive devices 7 and spherical hinge supports 8, and the two front...

Embodiment 2

[0030] Such as Figure 6 As shown, on the basis of Embodiment 1, two sets of identical hydraulic steering mechanisms 3 are symmetrically arranged on both sides of the two-degree-of-freedom hinge mechanism 2 to form Embodiment 2; two sets of symmetrically arranged hydraulic steering mechanisms 3 can be used to increase The stability of the vehicle when turning, improves the steering ability and dynamic characteristics of the vehicle, and meets the requirements of off-road driving in the wild.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com