Chain and flight conveyor assembly

A conveyor and scraper technology, applied in the field of chain and scraper conveyors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

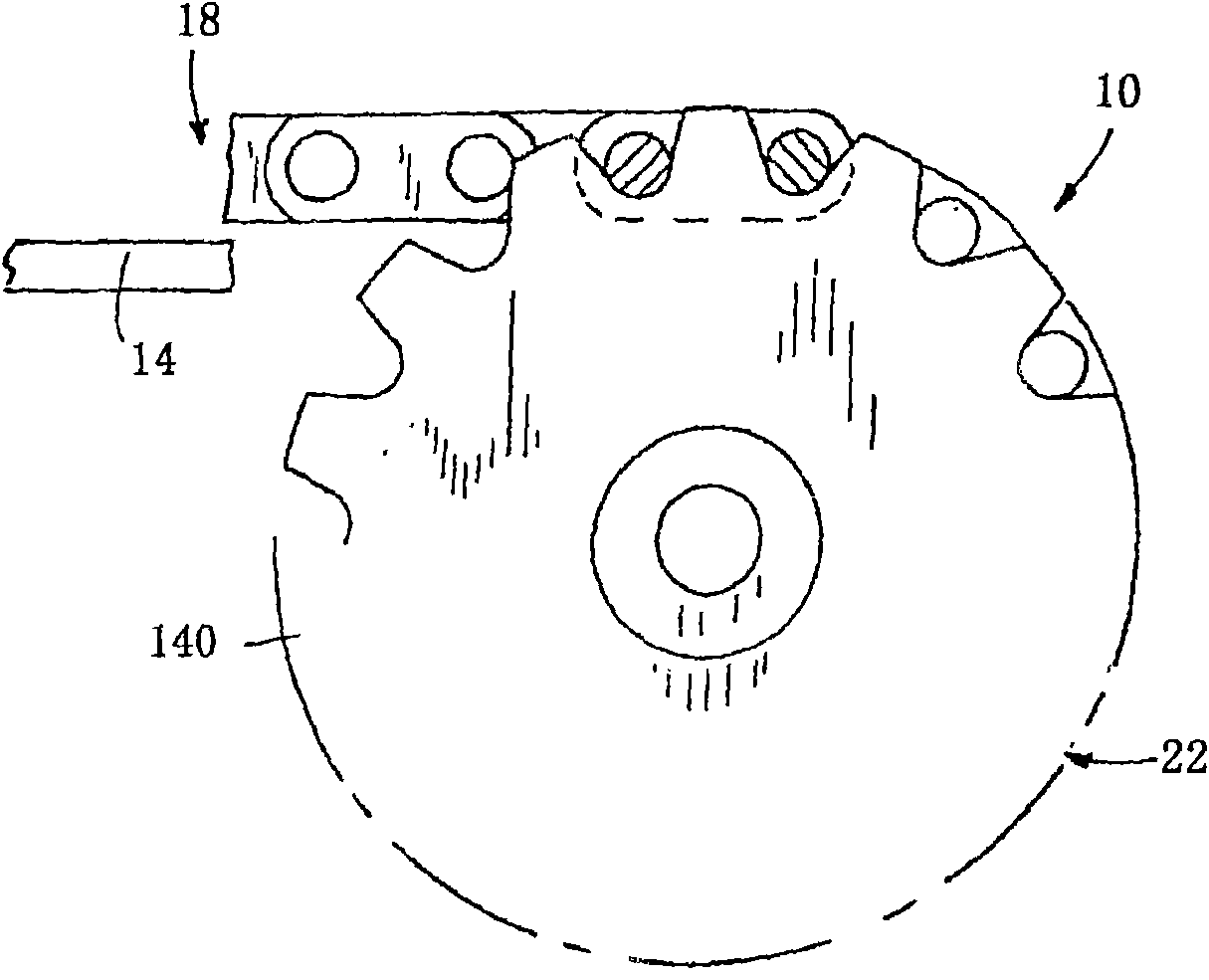

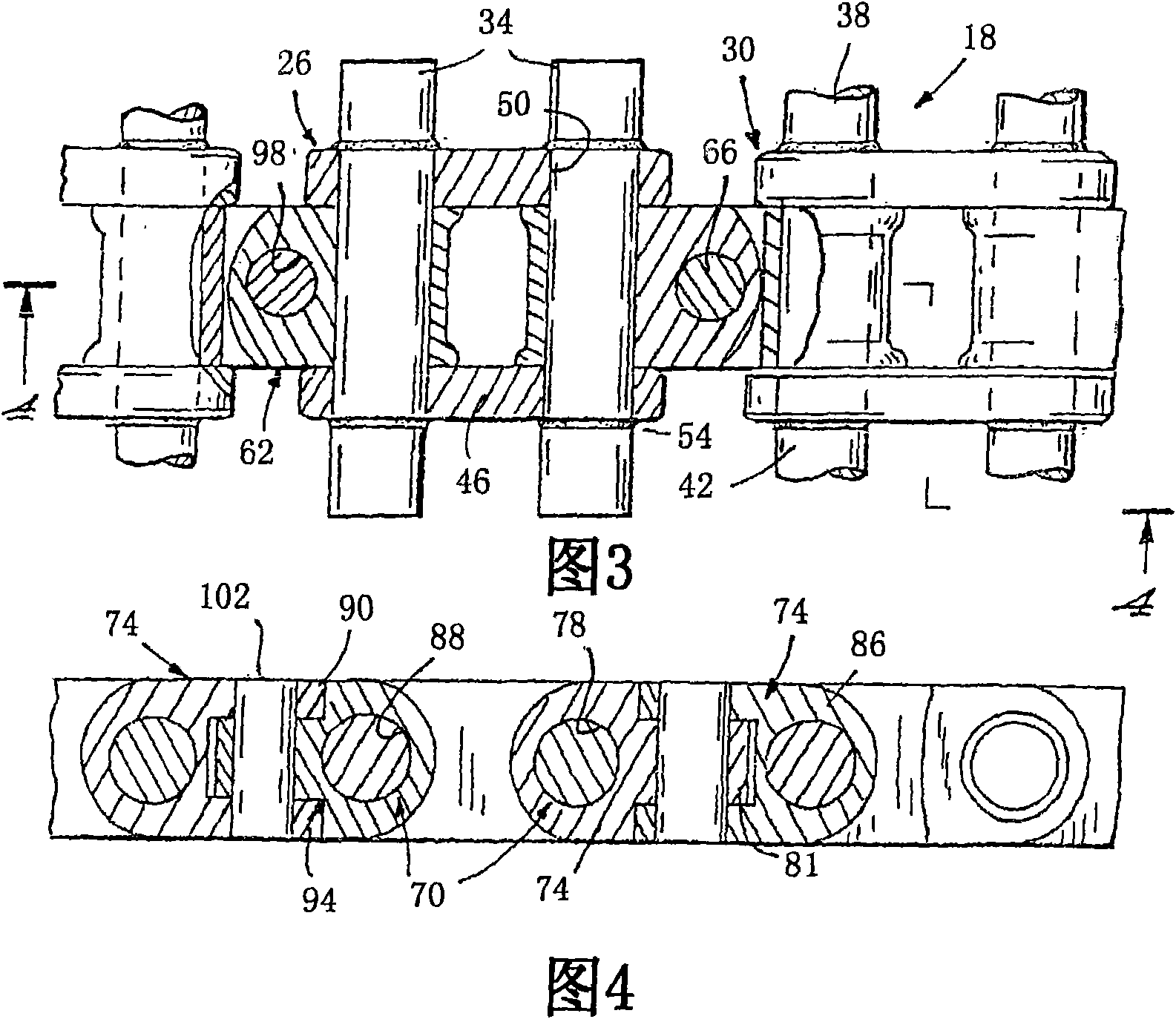

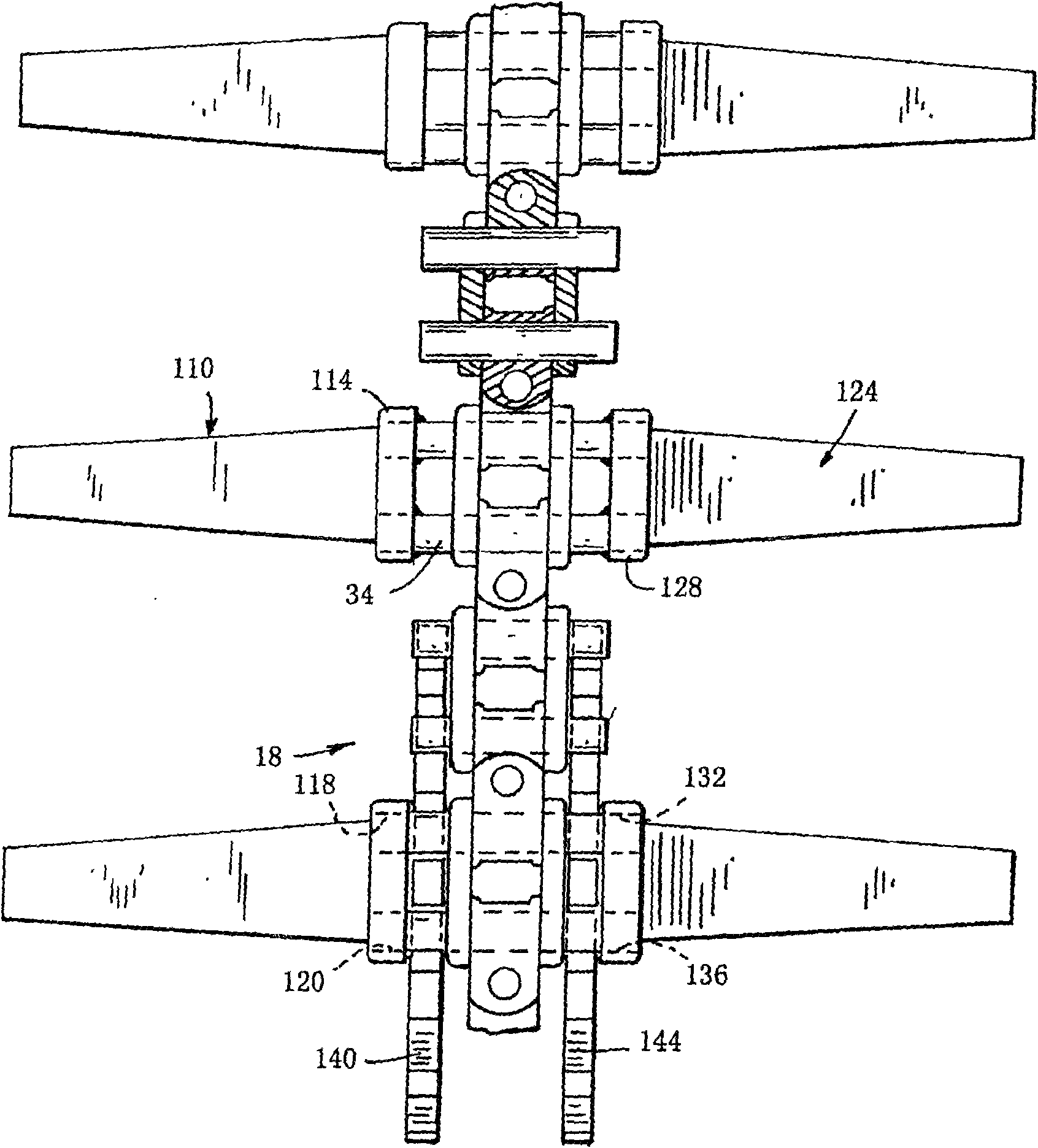

[0036] The disclosed embodiments are improvements on the above-described subject matter of the '932 patent, a description of which can be found in the "Summary of the Invention." More specifically, as Figure 5 As shown, the modifications relate to the structure of the first linkage assembly 26 and the second linkage assembly 30 . Still more specifically, as Figure 5 As shown, the improvements relate to the chain and flight assembly 118 and its use on a conveyor, the assembly including a first linkage assembly 126 and a second linkage assembly 130 . As mentioned earlier, as Figures 6 to 13 As shown with respect to the first linkage assembly 126, each linkage assembly also includes two spaced apart side plates 146, each side plate 146 having two spaced apart openings 150, each opening 150 receiving a different one of the transmission pin 134. The conveyor chain and flight assembly 18 also includes a swivel assembly 62 that connects the two link assemblies 26 and 30 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com