Weaving method for making a heating textile web and heating textile web

A heating layer and fabric technology, applied in fabrics, textiles and papermaking, ohmic resistance heating, etc., can solve problems such as breakage, conductive yarn damage, and reduced carpet heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

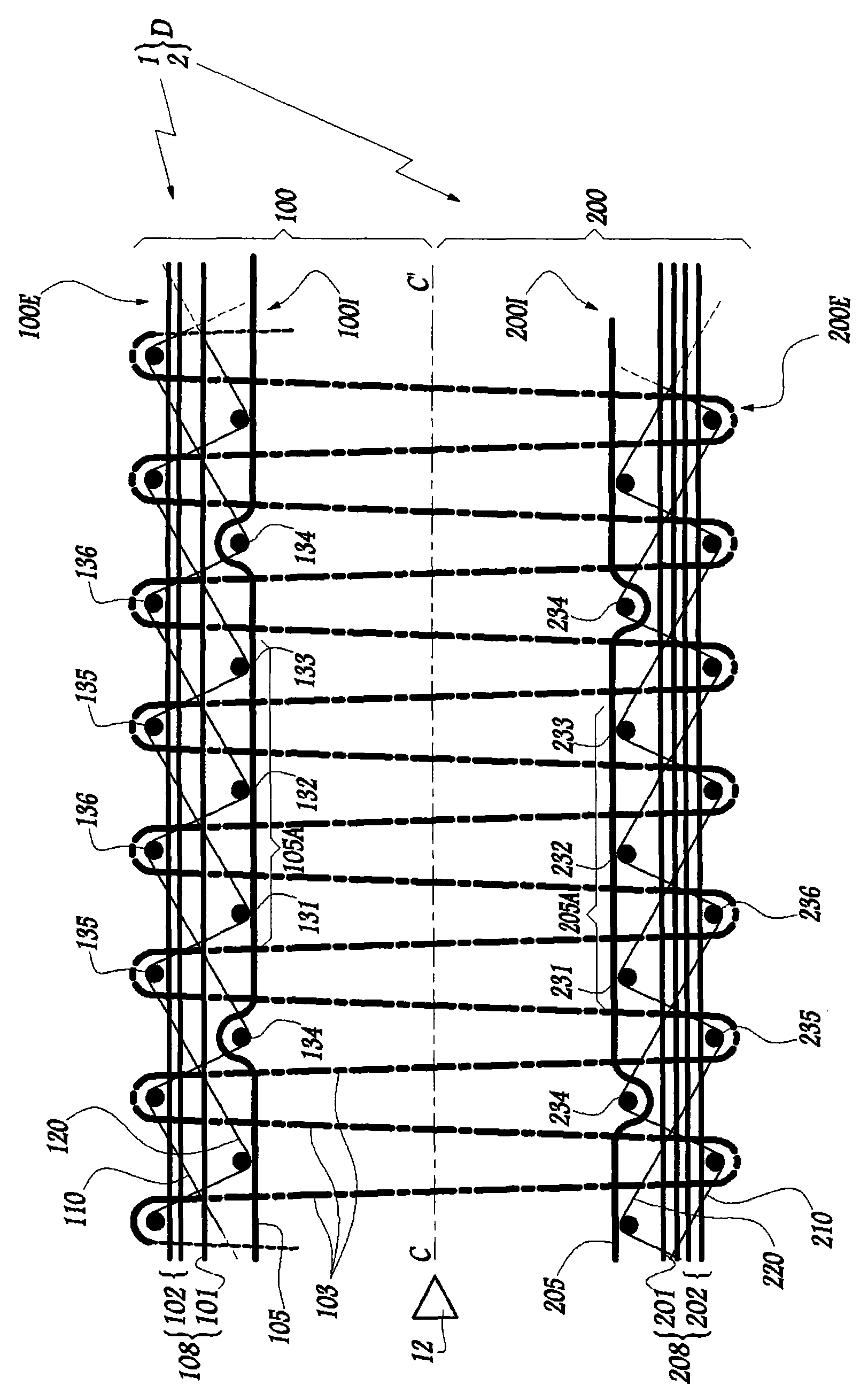

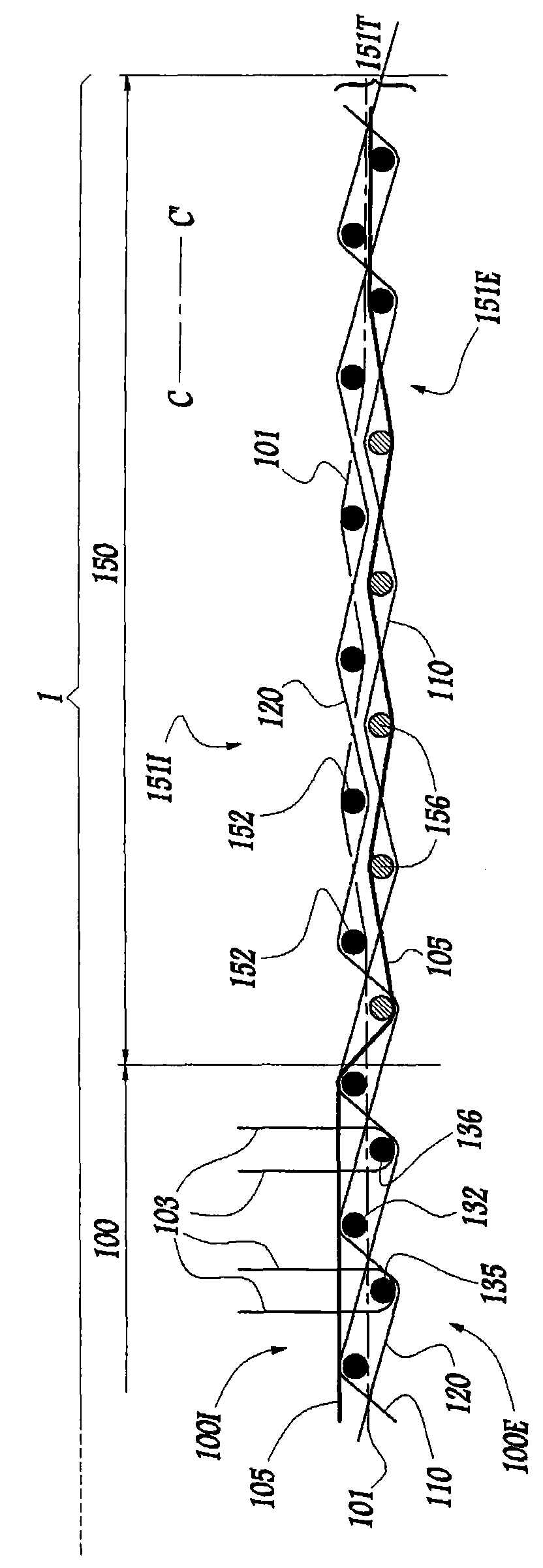

[0046] figure 1 Shown is a two-ply carpet D which is being woven by the method of the invention on the loom shown. Such looms have two weft insertion planes. The double layer carpet D consists of two pieces, an upper heating carpet 1 and a lower heating carpet 2, which are separated by a knife 12 after weaving.

[0047] The carpet 1 has a base fabric 108 which defines an outer side 100E and an inner side 100I of the carpet 1 . The outer side 100E comprises the back of the carpet 1 for contact with the ground or other support. The inner side 100I comprises the front side of the carpet 1 intended to face the volume to be heated.

[0048] The base fabric 108 includes binding threads 101 running or extending in the warp direction shown by the axis C-C'. The buried pile yarns 102, that is, those pile yarns that do not form a design pattern, are organized in the same manner as the binding thread 101. The buried pile yarn 102 is used to form the relief pile yarn 103 on the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com