Pipeline flexible check valve

A check valve, flexible technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of high use cost, large space occupation, inconvenient installation and maintenance, etc., to achieve long service life, prolong service life, Automatic control, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

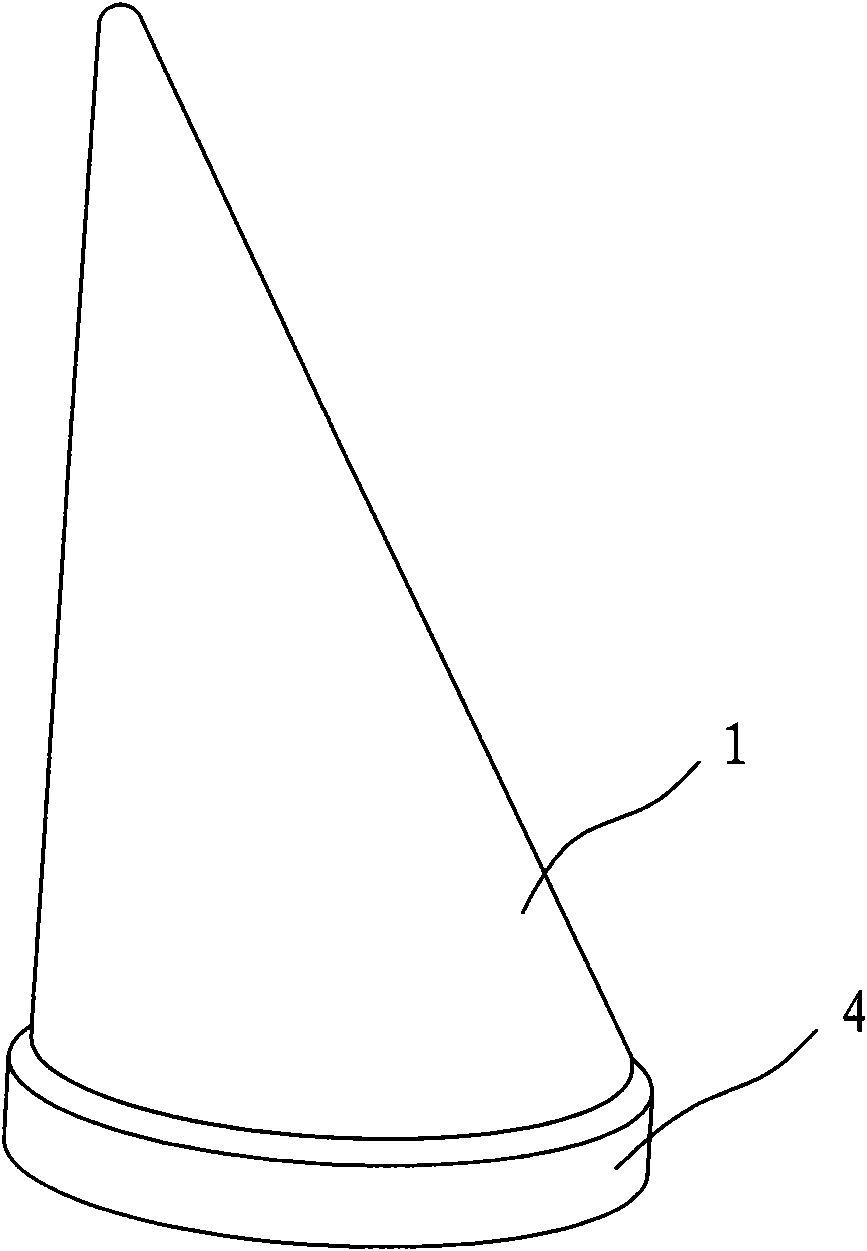

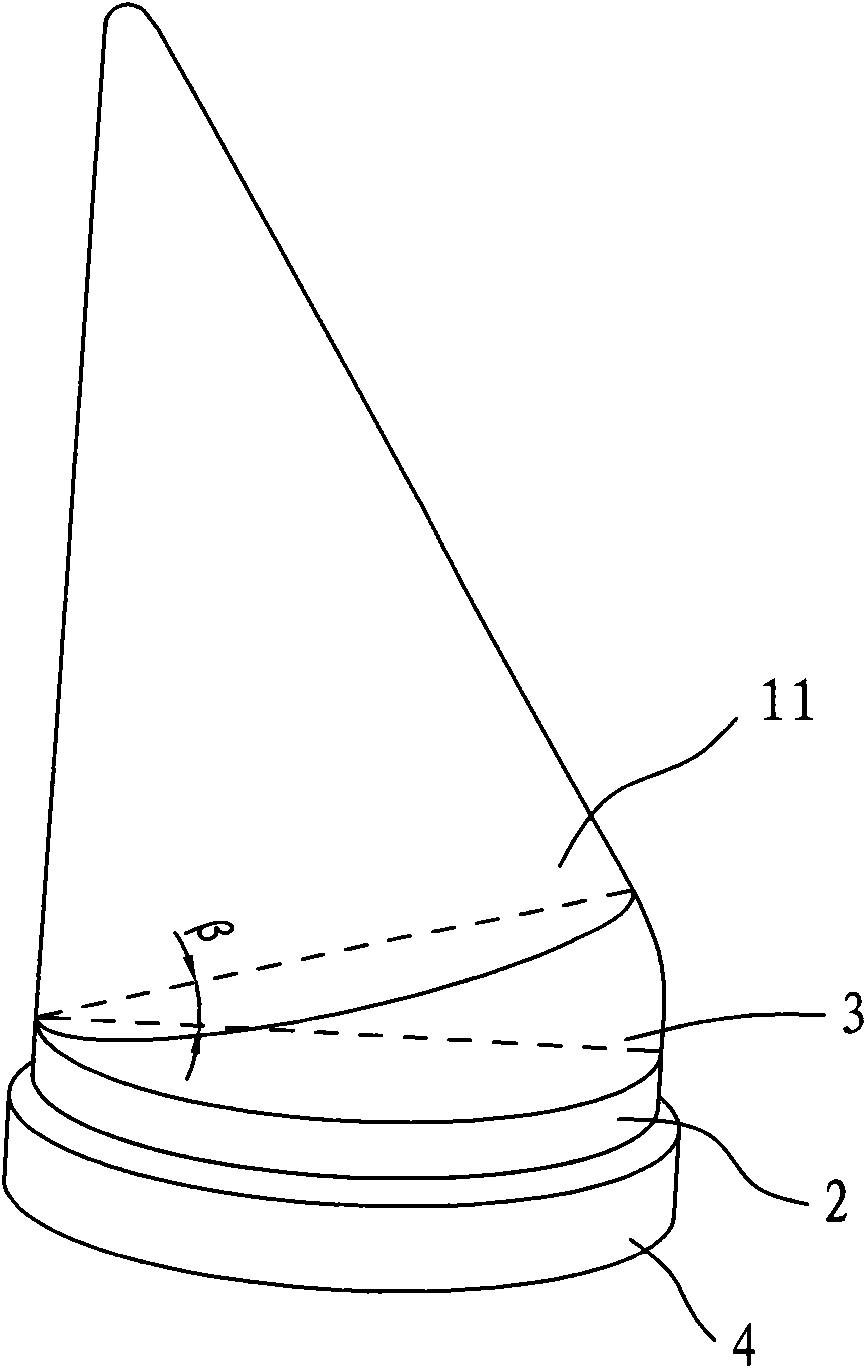

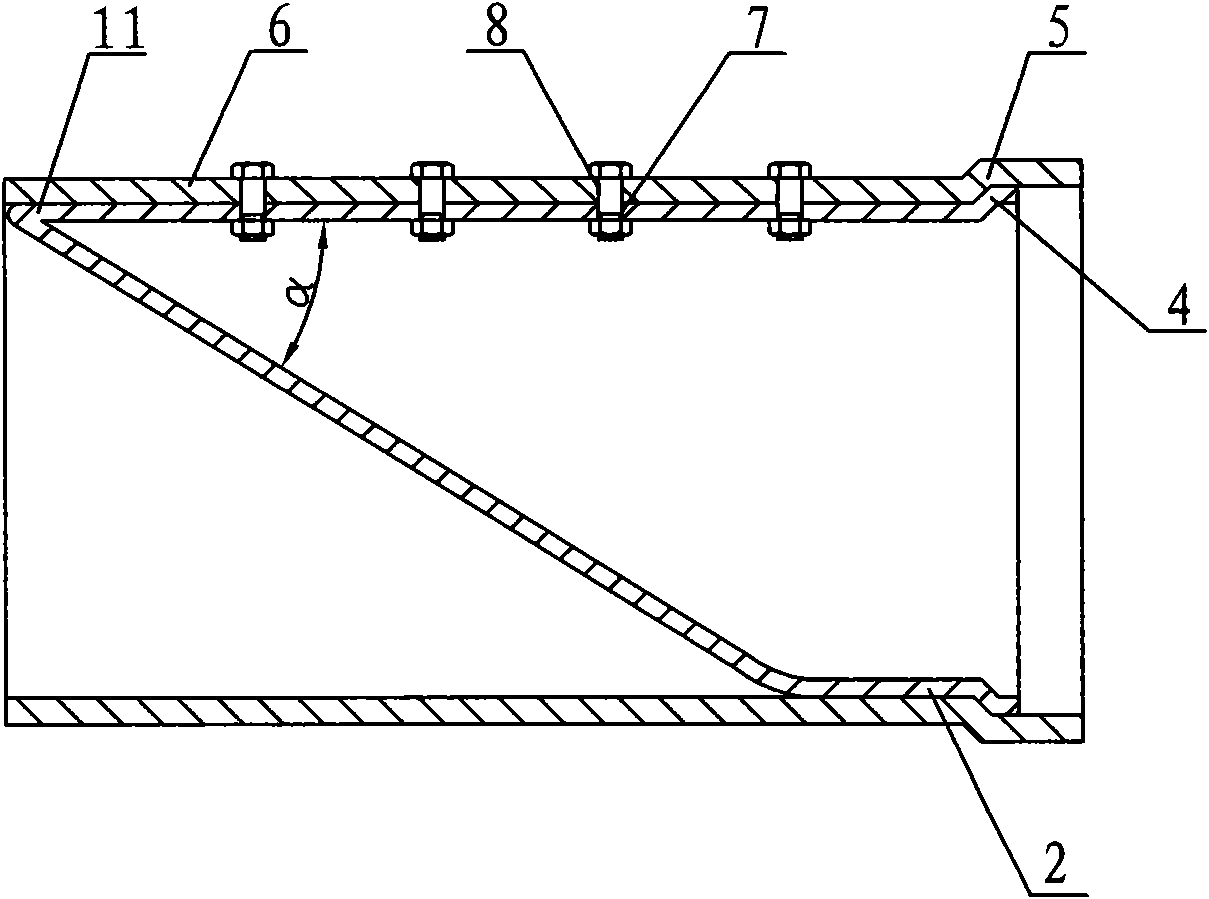

[0016] figure 1 , 2 . A pipeline flexible check valve shown in 3 mainly includes a valve cylinder 6 and a flexible valve core, the valve cylinder 6 is an engineering plastic pipe or a stainless steel pipe, the two ends of the valve cylinder 6 are flange structures, and one end of the valve cylinder 6 A seam 5 is provided, and a plurality of installation holes 8 are provided on the body of one side of the valve cylinder 6 . The flexible spool is figure 1 As shown in the tapered sleeve, the mouth of the tapered sleeve 1 is bonded to the seam 4, the closed apex of the tapered sleeve 1 is in contact with the inner wall of the valve cylinder 6, and the taper in the straight line direction from the closed apex of the tapered sleeve 1 to the seam 4 The sleeve wall is bonded to the inner wall of the valve barrel 6 and is locked and connected by a screw, and the stop 4 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com