Vapor compression refrigeration unit

A refrigeration unit and vapor compression technology, applied in the field of economizer, can solve the problems of not being able to make full use of the suction capacity of the compressor and the efficiency reduction of the economizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

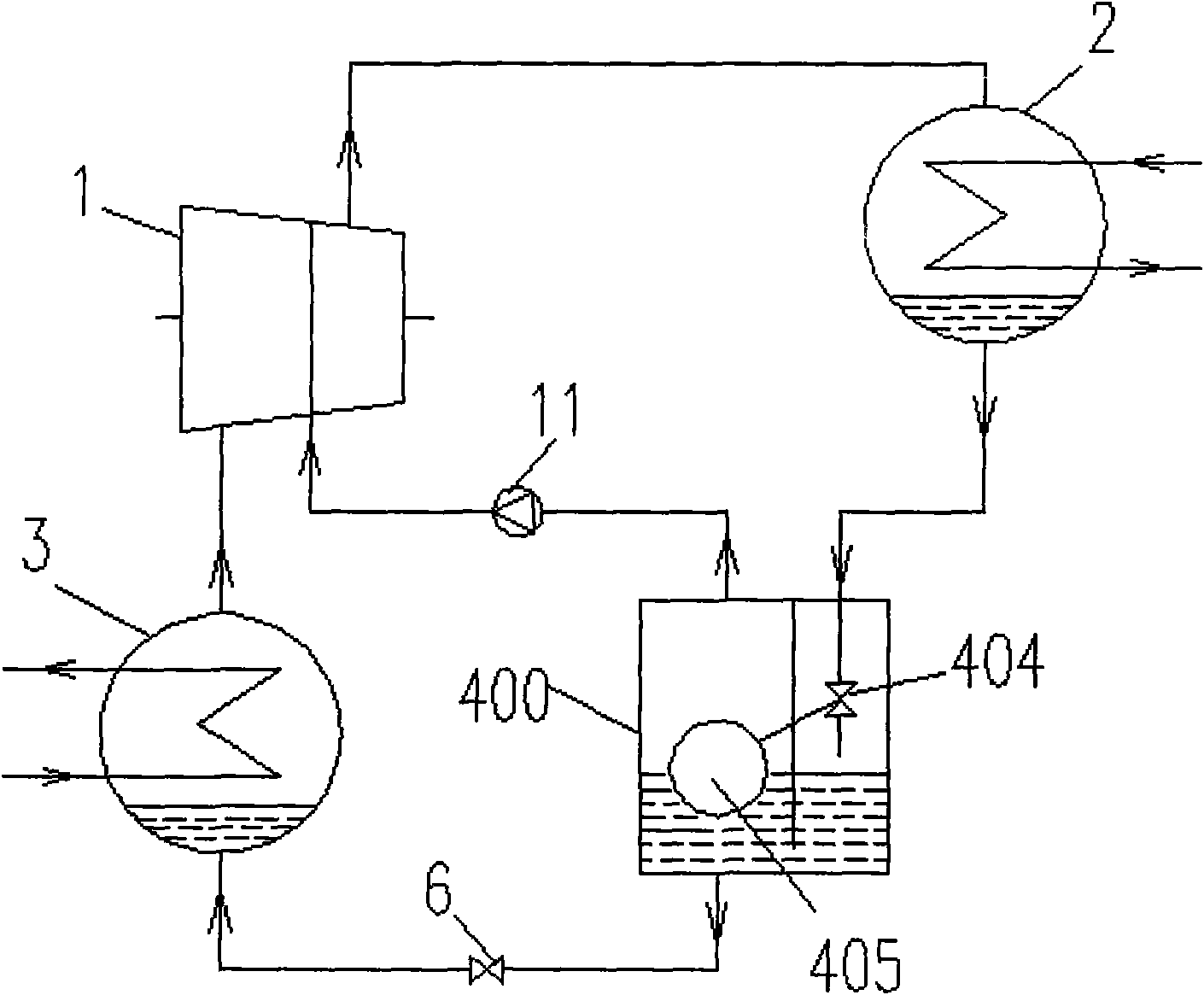

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

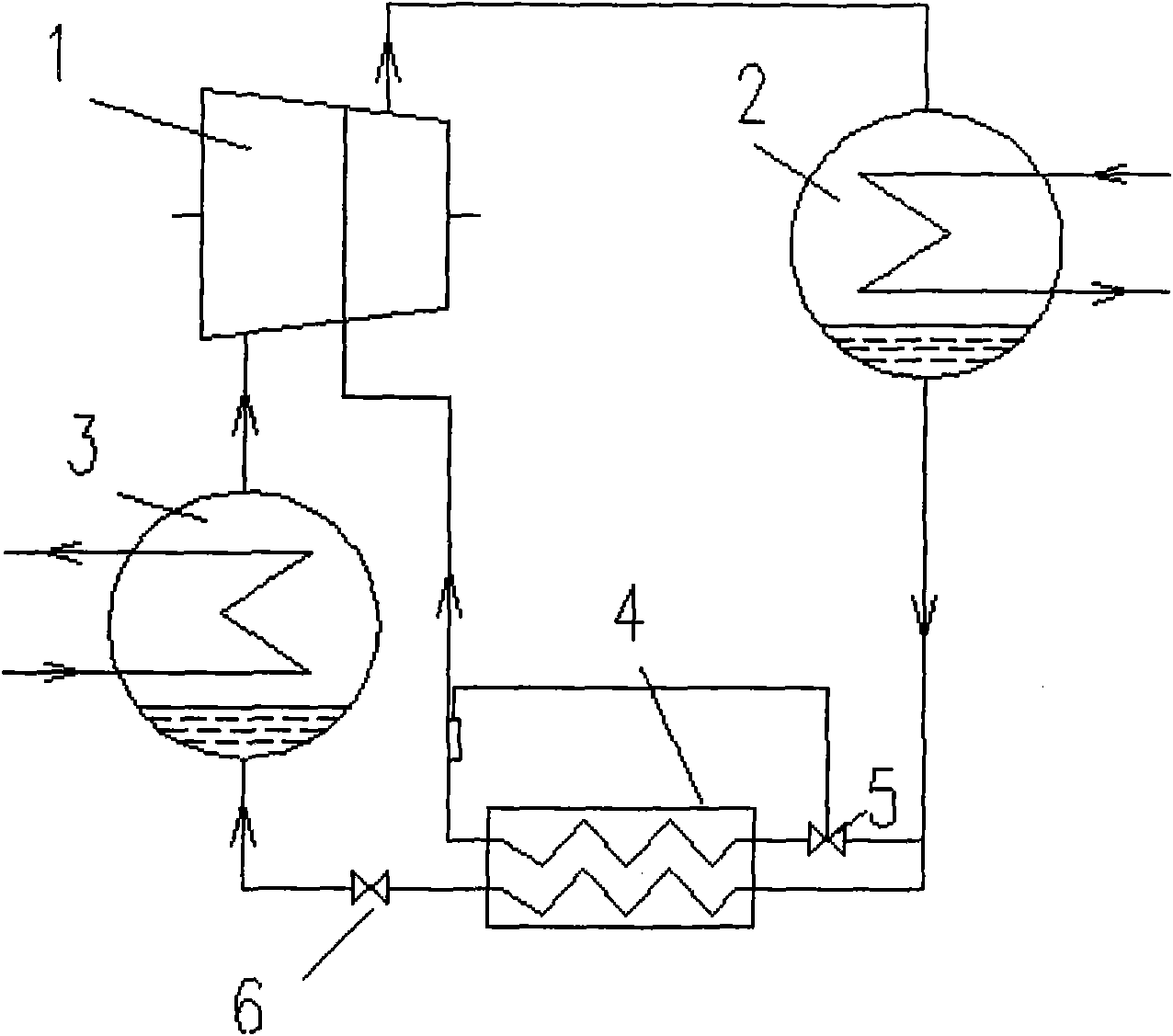

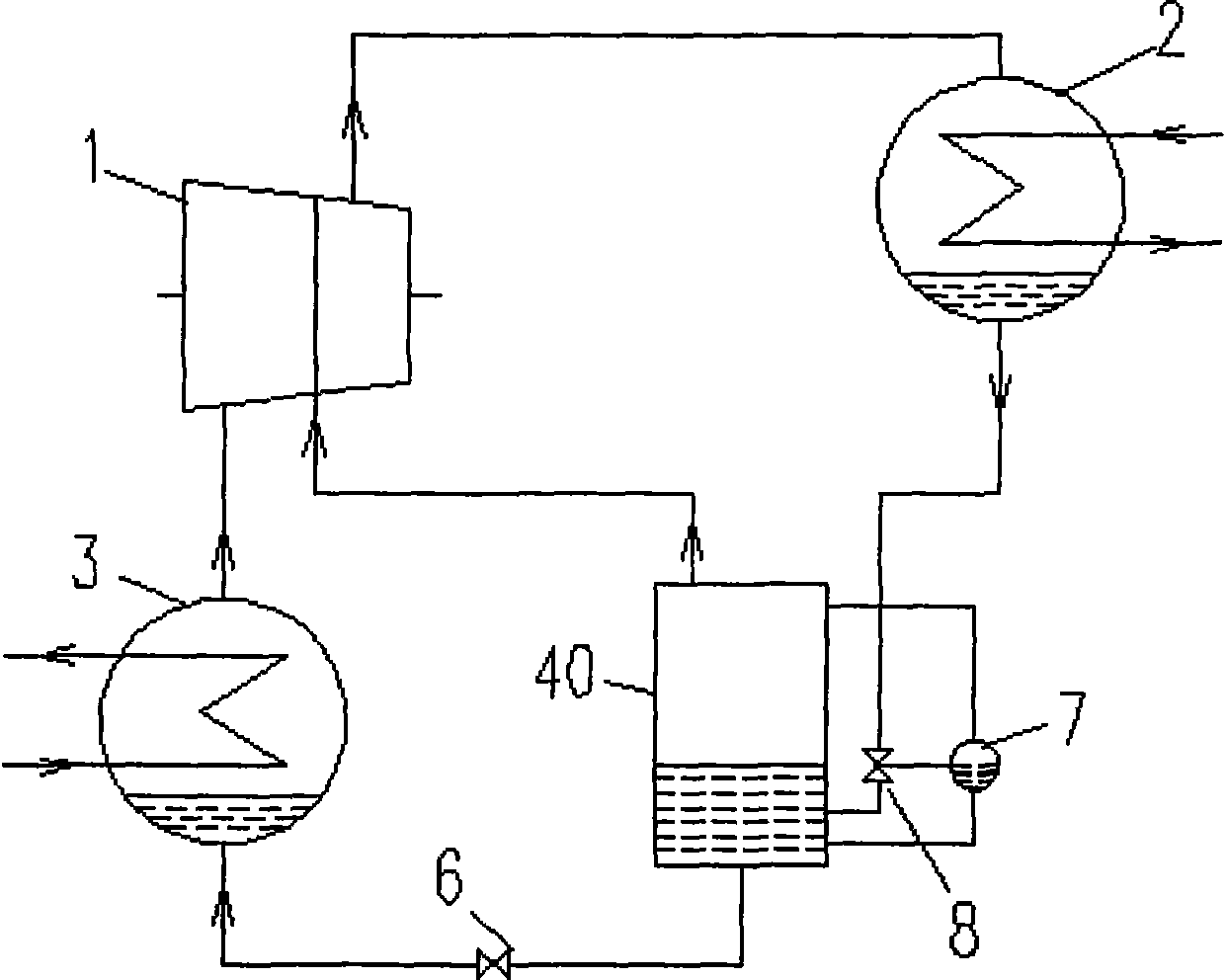

[0019] Depend on image 3 , Figure 4 , Figure 5 It can be seen that the present invention includes: a compressor 1, a condenser 2, and an evaporator 3; a flash cylinder 400 is also included; the liquid inlet 401 at the upper end of the flash cylinder 400 is connected to the condenser 2, and the gas outlet 402 at the upper end passes through The one-way valve 11 is connected with an input port of the compressor 1, and the liquid outlet port 403 at the lower end is connected with the evaporator 3 through the second throttle valve 6; the flash cylinder 400 includes: a pair of liquid inlet ports 401 connected coaxial throttling orifice 404; one of the coaxial throttling orifice 404 is fixed and the other rotates; a floating ball mechanism 405 placed on the liquid; the floating ball mechanism 405 is connected with the joint One of the orifice pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com