Drill pipe with tool joints

A technology of drill joints and drill pipes, which is applied in the direction of drill pipes, pipes/pipe joints/fittings, drill pipes, etc., can solve the problems of not being able to enhance the durability of drill joints, and achieve the effect of enhanced durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

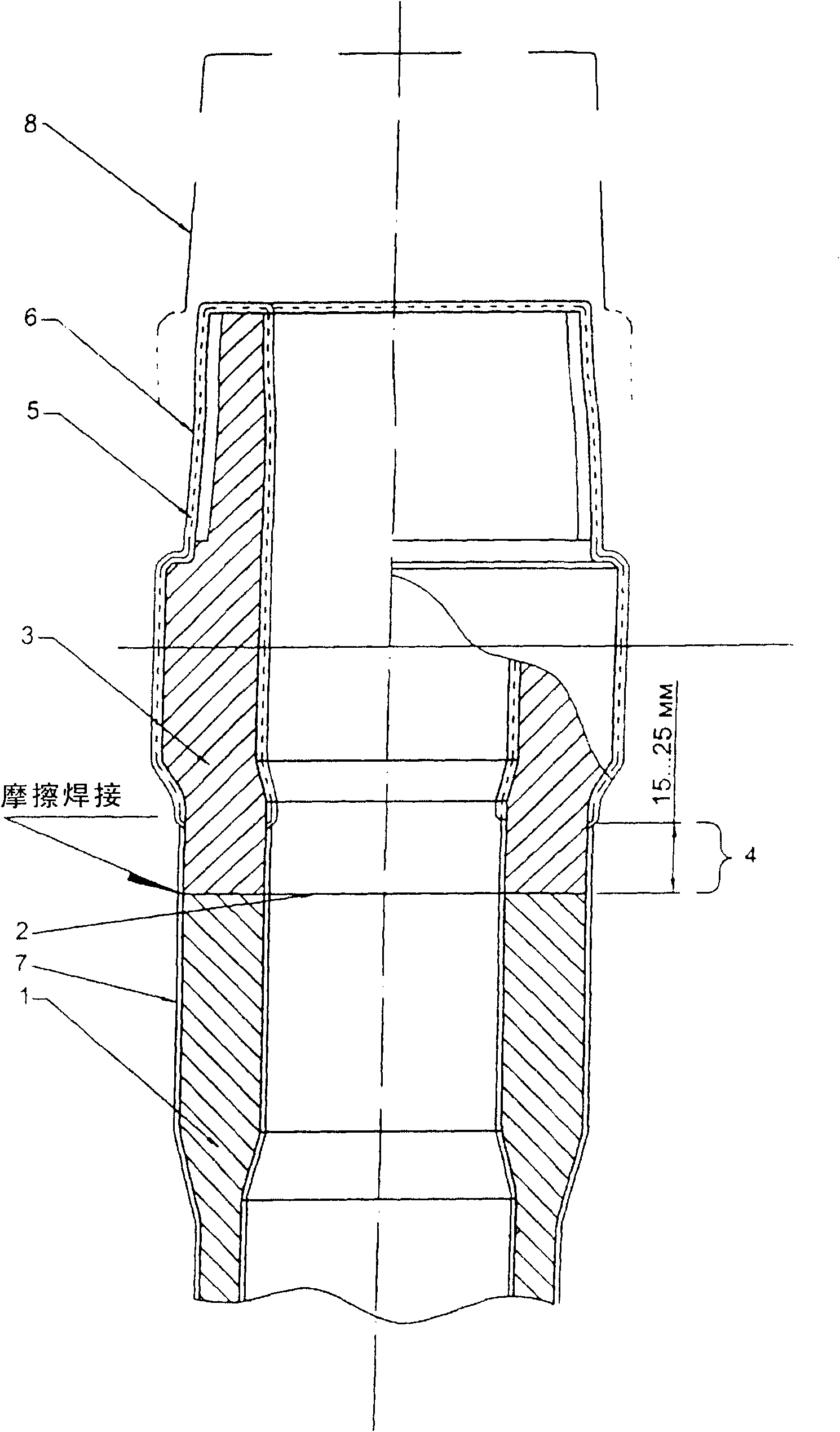

[0014] The drill pipe consists of a pipe body 1 permanently connected at both ends 2 (welded connections) with connection joints (tool joints) 3 with external or internal tapered threads. For example, Figure 3 contains a fitting 3 with an external thread (pipe nipple). The other pipe end with an internally threaded joint is not shown in the figure. The relevant specifications of the pipe ends are completely similar.

[0015] The entire surface of the joint, except for the section 15-25 mm from the welding point, is treated with a coating 5, which is applied by means of thermal diffusion galvanizing. The thickness δ of the coating 5 is in μ (micrometer), which is 0.09 to 0.13K, where К is the thread taper. This correlation was determined experimentally by taking taper values in the range from 1 / 6 to 1 / 4, which is the most commonly used value for tool joint threads.

[0016] The coating 5 is covered with a phosphating layer 6 . The phosphating layer is applied both to the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap