Chopping block with sharpener

A knife sharpener and cutting board technology, applied in grinding/polishing equipment, grinding/polishing hand tools, household utensils, etc., can solve problems such as unsanitary and food contamination, and achieve a high degree of hygiene, strong integrity, and operation. Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

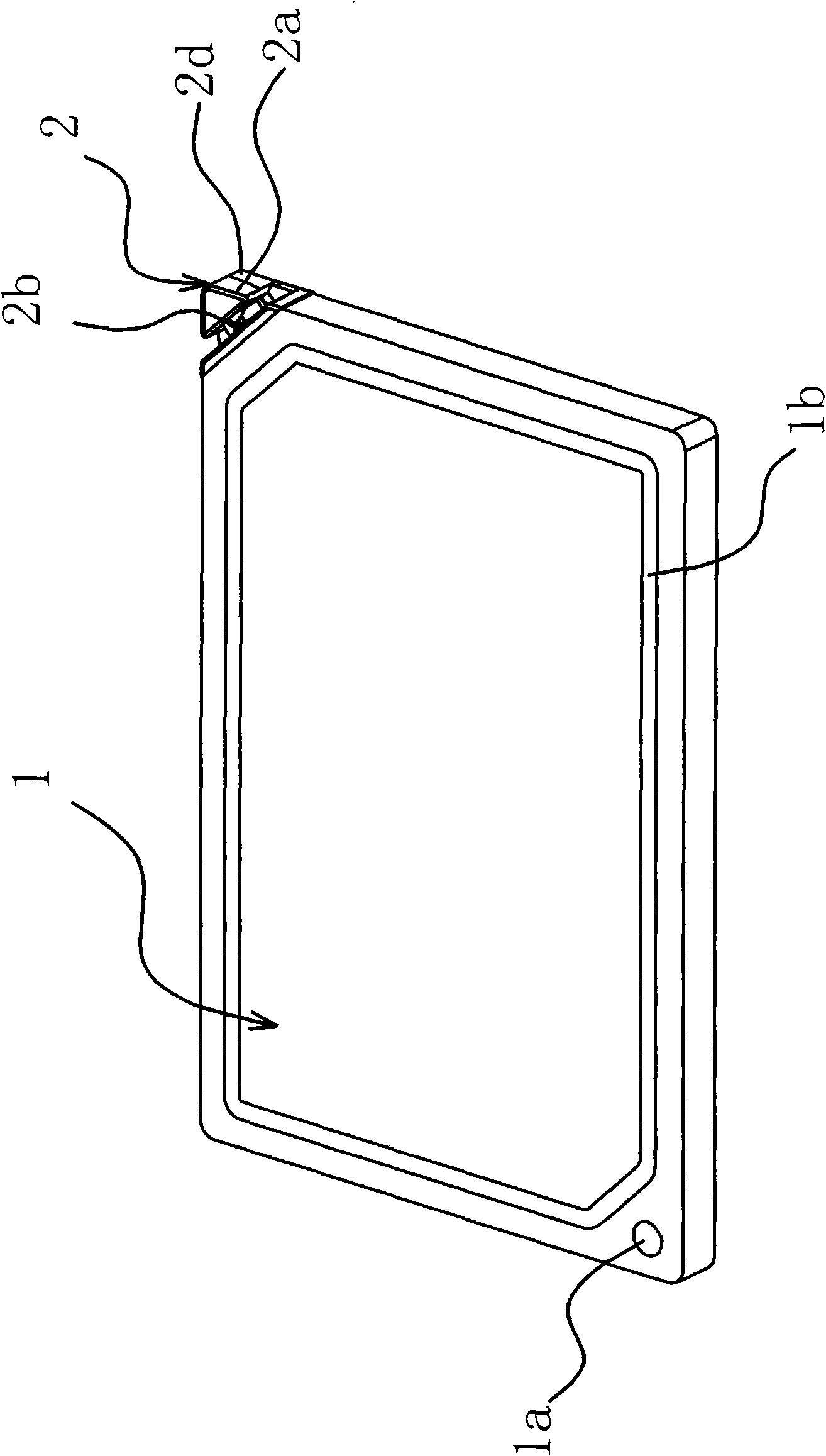

[0034] Such as figure 1 As shown, the cutting board with a knife sharpener includes a board body 1 and a knife sharpener 2. The board body 1 has a hanging hole 1a, and the board body 1 has a closed stagnant water tank 1b on the use board surface.

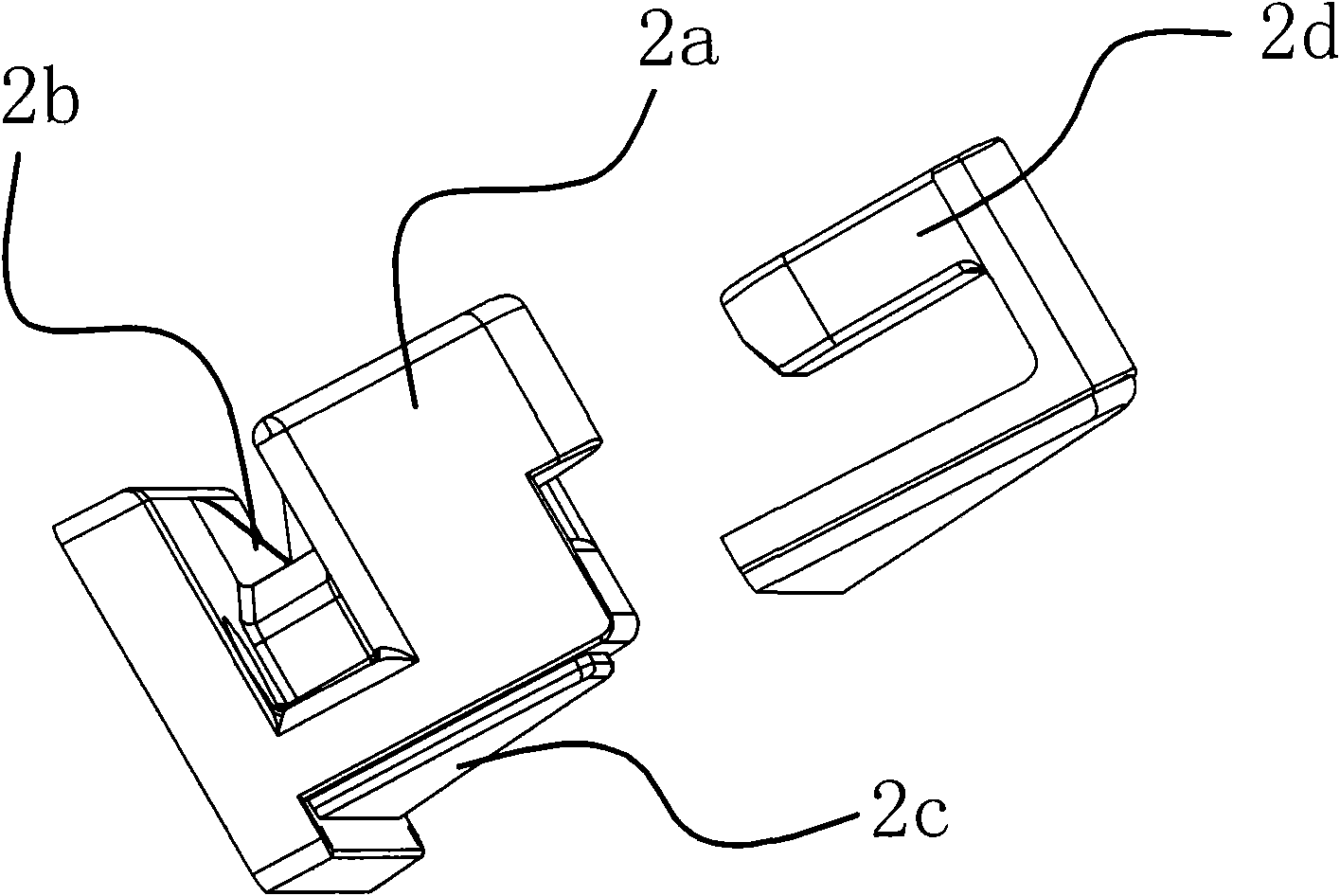

[0035] Such as figure 2 As shown, the sharpener 2 is composed of a base body 2a, a sharpening blade 2b, a grinding block 2c and a dust cover 2d. The substrate 2a is made of stainless steel, the sharpening blade 2b is made of alloy steel into a flat key shape, and the grinding block 2c is made of diamond.

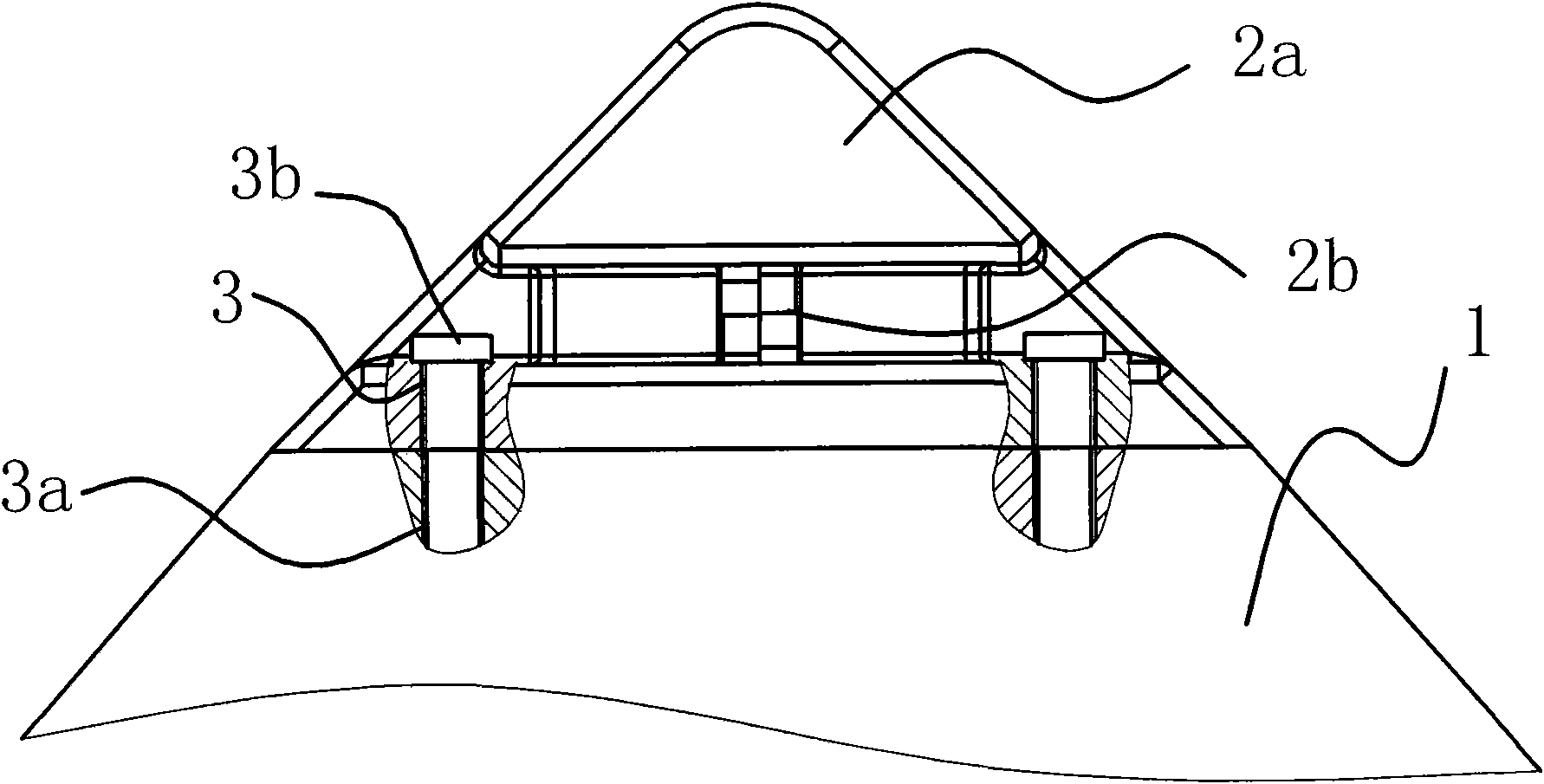

[0036] One side of the base body 2a is provided with a sharpening notch, which is on the same side as the use surface of the chopping board, and two interlaced sharpening blades 2b are embedded in the sharpening notch, forming a wedge-shaped grinding between the sharpening blades 2b. The opening angle of the wedge-shaped grinding mouth ranges from 20° to 60°. A grinding block 2c is inlaid on the other side opposite to the abo...

Embodiment 2

[0041] Such as Figure 4 As shown, the structure and principle of the present embodiment are basically the same as those of the first embodiment, except that the edge of the plate body 1 in this embodiment is provided with a groove 4a, and the mounting surface of the base body 2a is fixedly connected with a slot 4 . The knife sharpener 2 is fixed on the edge of the plate body 1 by cooperating with the slot 4 and the groove 4a on the edge of the plate body 1 .

Embodiment 3

[0043] Such as Figure 5 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the edge of the plate body 1 in this embodiment has a threaded hole 5a, and the mounting surface of the base body 2a is fixedly connected with a threaded column 5 . The knife sharpener 2 is fixed on the edge of the plate body 1 by connecting the threaded column 5 with the threaded hole 5 a on the edge of the plate body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com