Quick connecting device for punch top and mandril of perforator

A technology of quick connection and head ejector, applied in the direction of metal rolling, manufacturing tools, mandrels, etc., can solve the problems that the thread of the plug cannot be aligned with the thread of the union, the large disassembly tool cannot be used, and it is difficult to rotate the plug. The effect of reducing the workload of workers, simplifying the steps of online head replacement, and reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

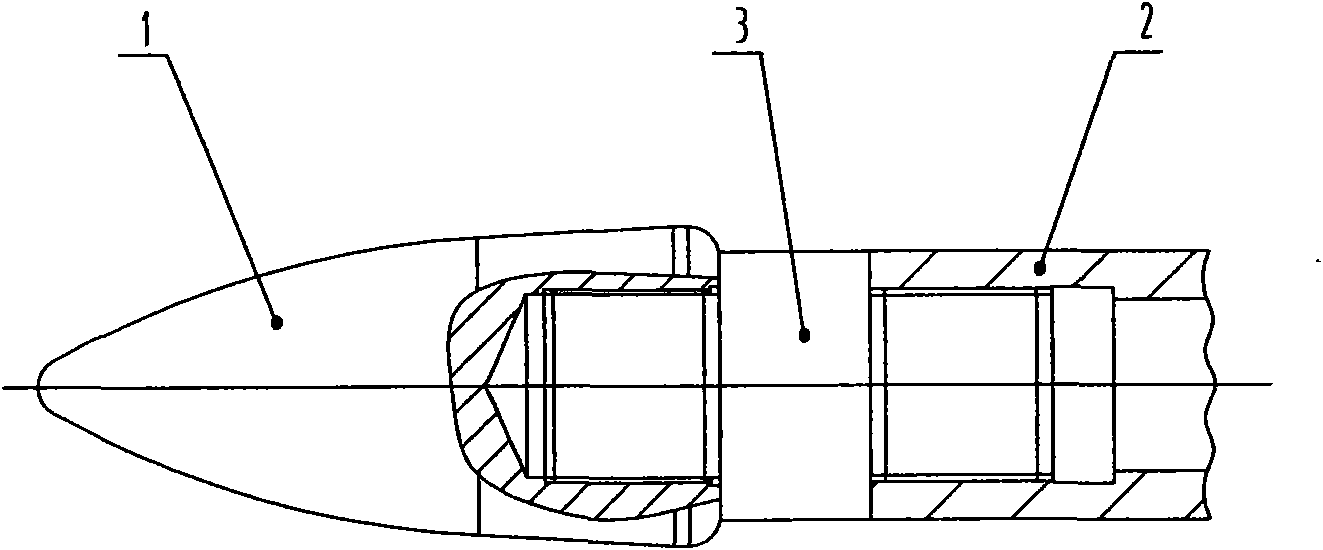

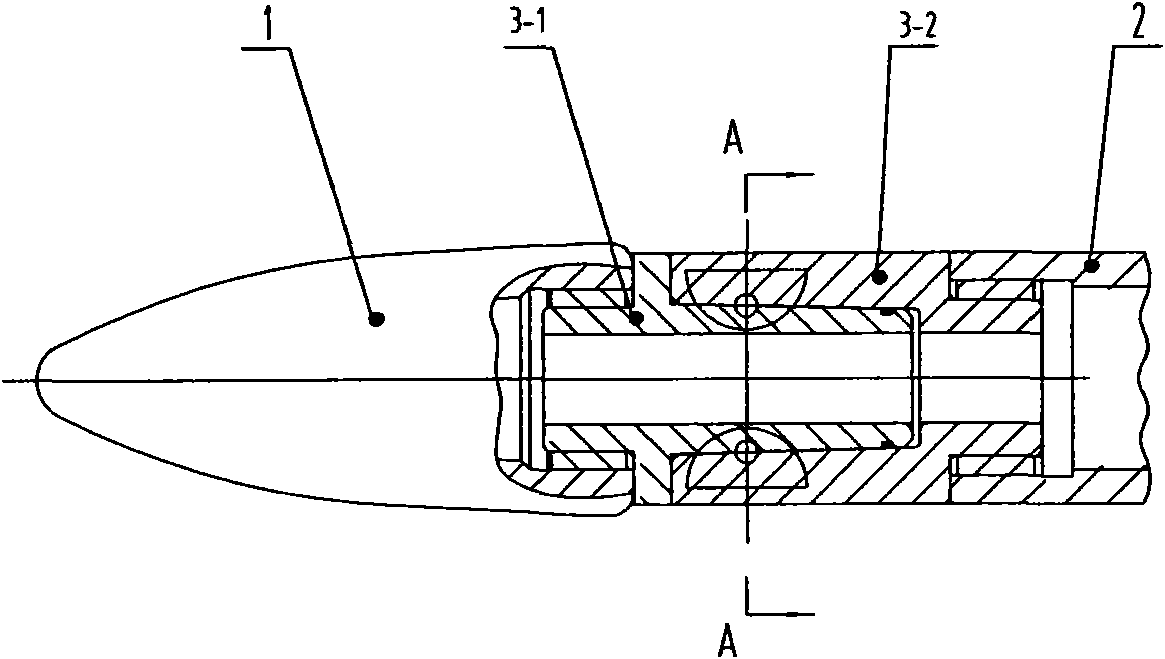

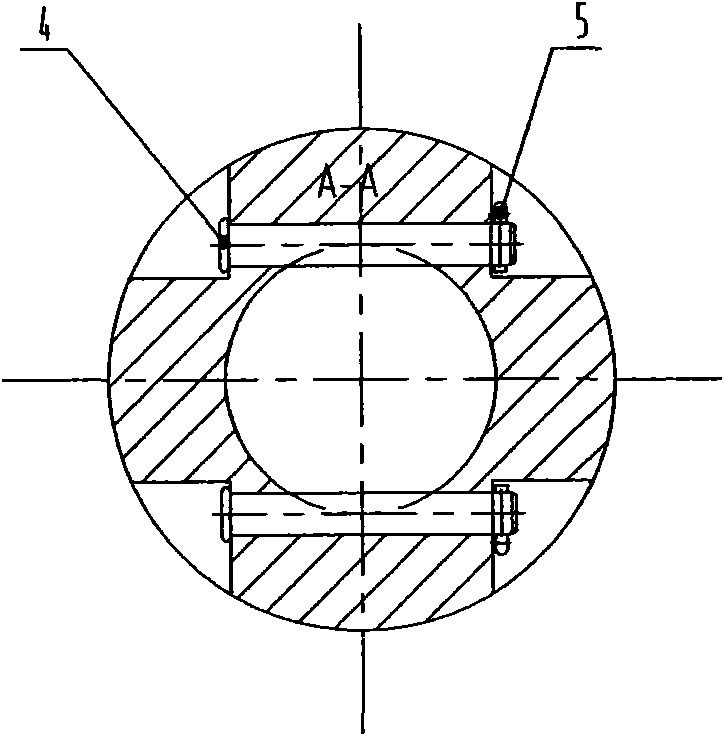

[0012] Such as figure 2 , image 3 As shown, a quick connection device for the punching rod of the piercing machine, including: the plug 1, the push rod 2, and the joint 3 connecting the top and the push rod; the joint 3 consists of the joint 3-1 of the plug and the joint Union 3-2 is composed of one end of the jack joint 3-1 with external threads, and the other end is a guide cone with an outer wall with an annular groove, and one end with external threads is connected to the top 1; the ejector joint 3-1 2. One end has an external thread, and the other end is a guide cone hole matched with the guide cone, and a pin hole is arranged corresponding to the annular groove in its transverse direction, and one end with an external thread is connected to the ejector rod 2; the plug The cone of the joint 3-1 matches the guide cone hole of the joint 3-2 of the push rod, and the annular groove of the joint 3-1 of the top joint coincides with the pin hole of the joint 3-2 of the push r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com