Steam ironing device comprising a rearward inlet

A technology of ironing device and inlet cover, which is applied to washing devices, hand irons, household appliances, etc., can solve the problems of complex injection molding, obstruction, high cost of structure, etc., and achieve the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

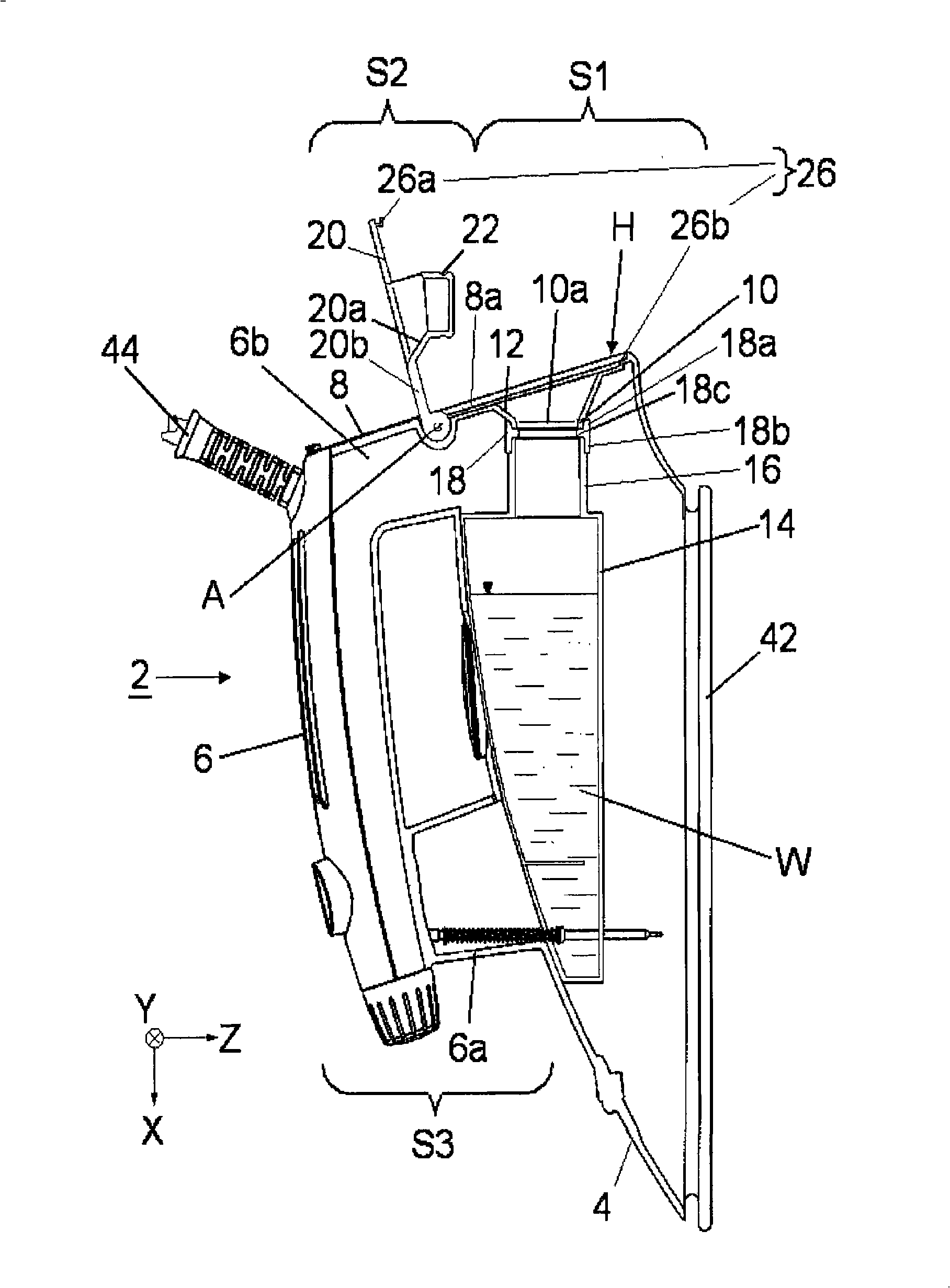

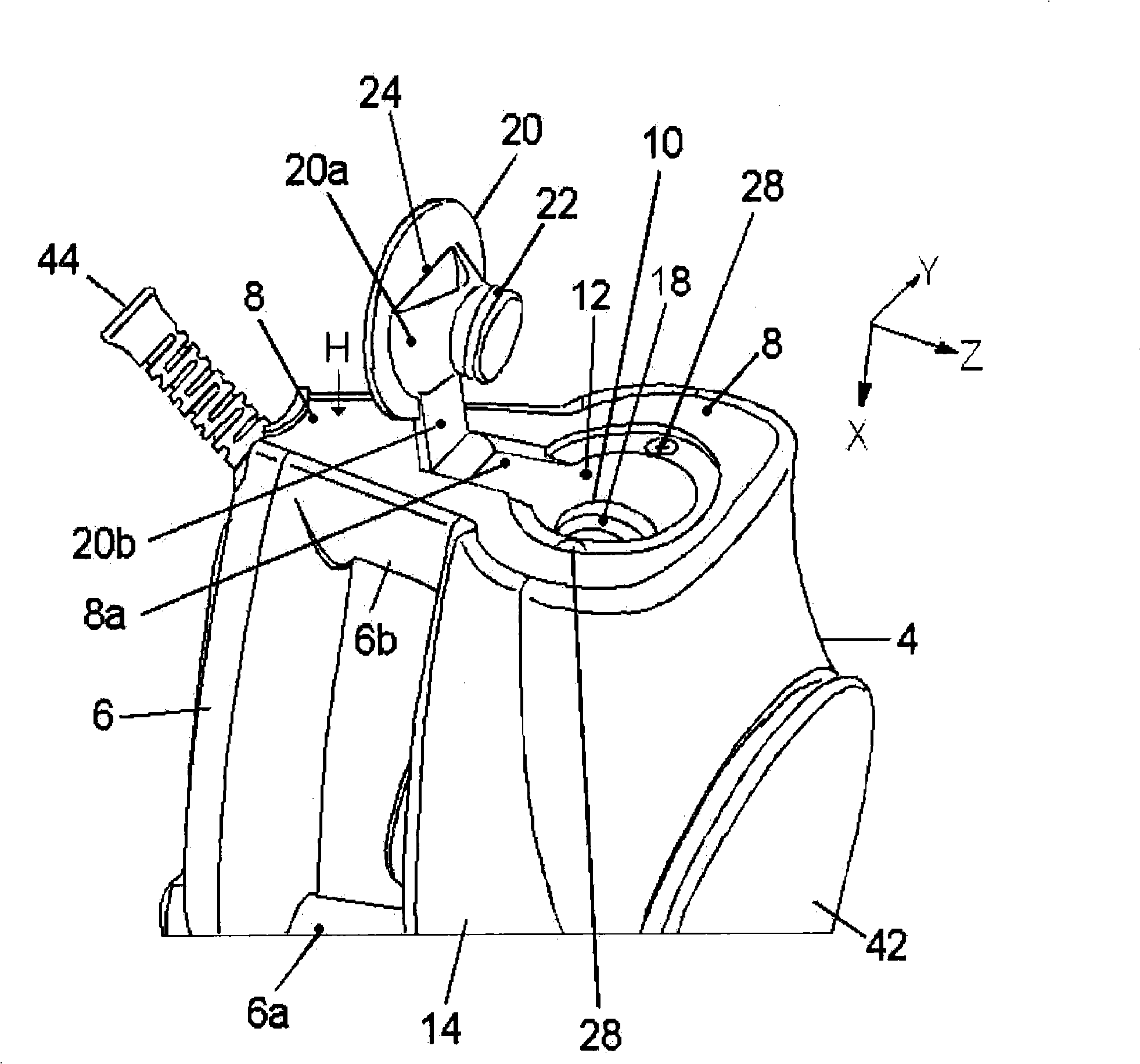

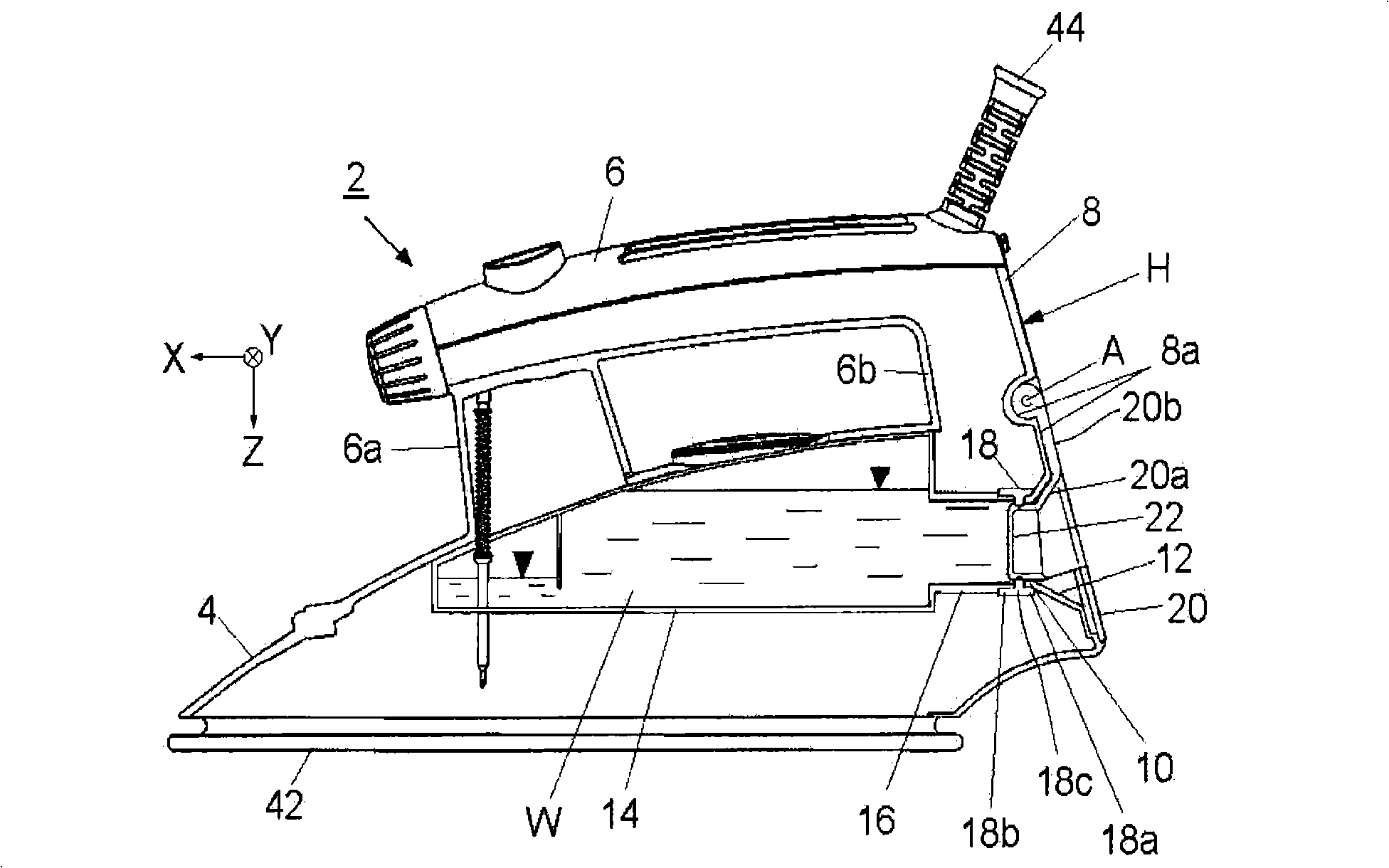

[0045] exist figure 1 shows a schematic longitudinal section of a steam iron 2 according to the invention upside down in a position suitable for injecting water W. The longitudinal, transverse and vertical directions of the steam iron 2 are indicated in the drawing with the references X, Y and Z in a Cartesian coordinate system. The steam iron 2 has a housing 4 made of synthetic material divided into different parts, with a housing main part S1 and an arc-shaped handle 6 protruding therefrom. The front and lower handle brackets 6a are figure 1 In the depiction, it is formed by the front part S3 of the housing handle, and the handle frame 6b behind the back is formed by the rear part S2 of the housing handle. The rear side of the housing handle rear part 2 together with the rear side of the main housing part S1 essentially forms the flat rear side H of the housing 4 .

[0046]Furthermore, said rear side H serves as a support surface, which is designed for placing the steam i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com