Cutting edge gap back milling cutter numerical control machining method

A processing method and technology of back milling cutter, which is applied in metal processing equipment, milling machine equipment, program control, etc., can solve the problems of back milling cutter processing method without cutting edge space, unable to meet production requirements, time-consuming and laborious operation, etc. Achieve the effects of wide application range, guaranteed machining accuracy, and flexible input parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

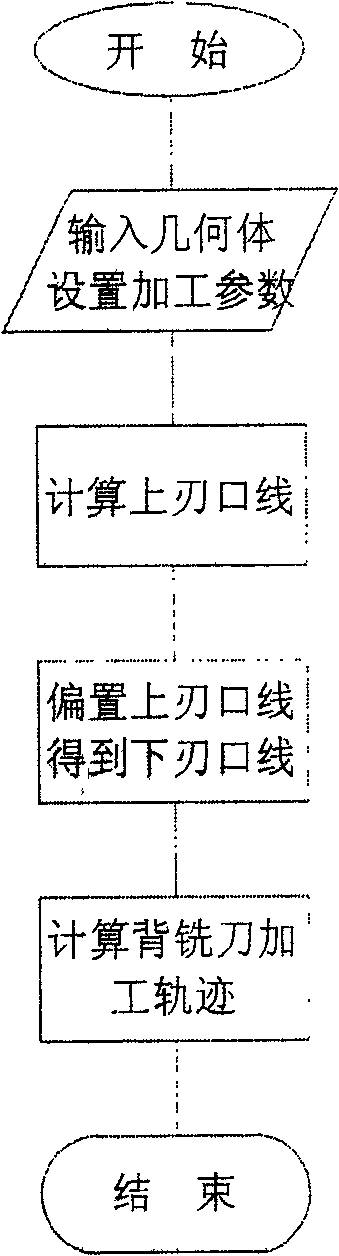

[0009] Such as figure 1 Shown: a CNC machining method of back milling cutter with cutting edge gap, which is carried out according to the following steps: (1) Input geometry, tool and set cutting edge height, final margin of cutting edge side, side margin of cutting edge gap, etc. Processing parameters; (2) Calculate the upper cutting edge line according to the profile allowance and the final allowance of the cutting edge side; (3) Offset the upper cutting edge line according to the cutting edge height to obtain the final lower cutting edge line; (4 ) The cutting edge line below is the back milling tool path for calculating the cutting edge gap based on the calculation of the cutting edge gap side allowance.

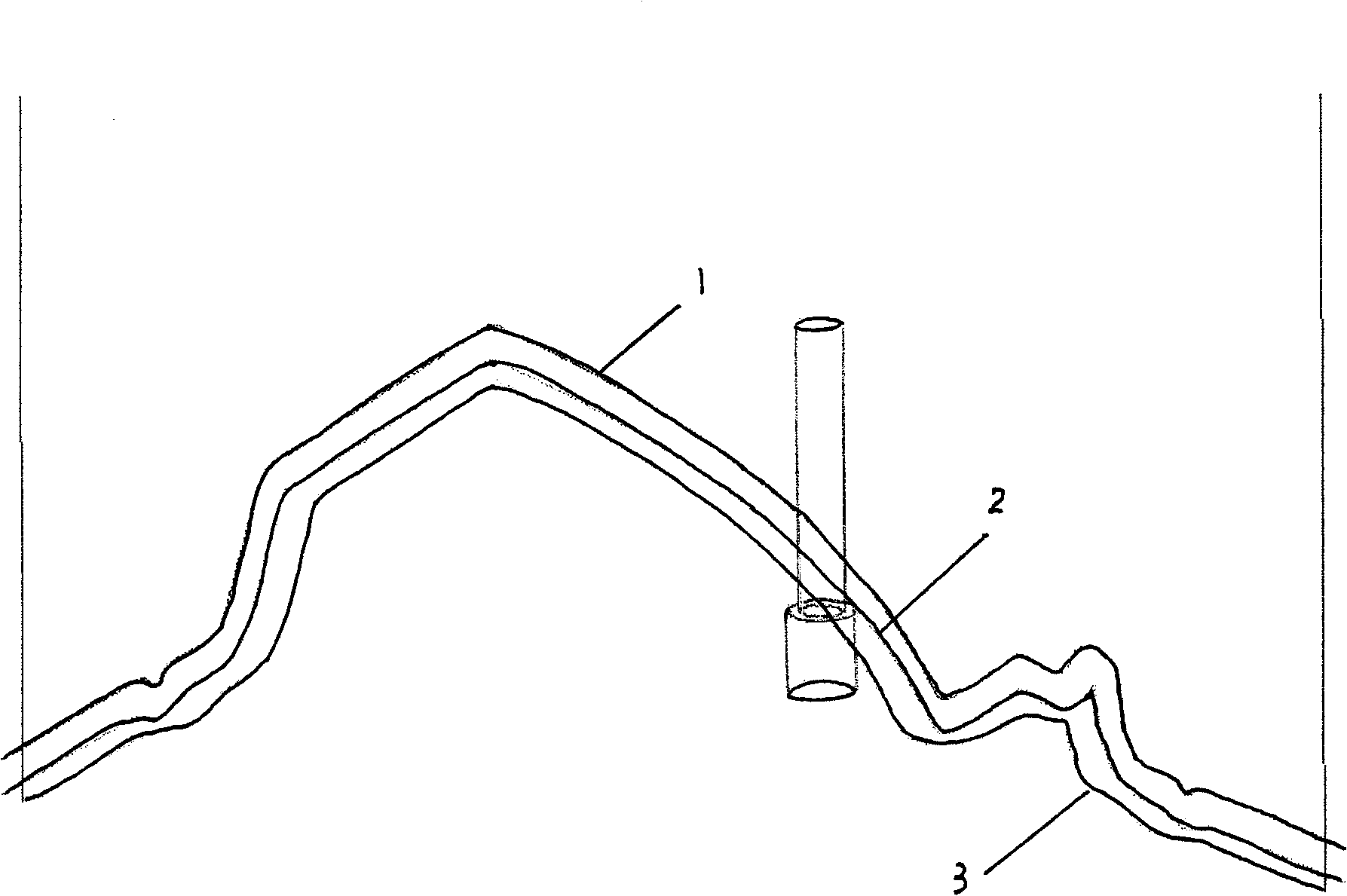

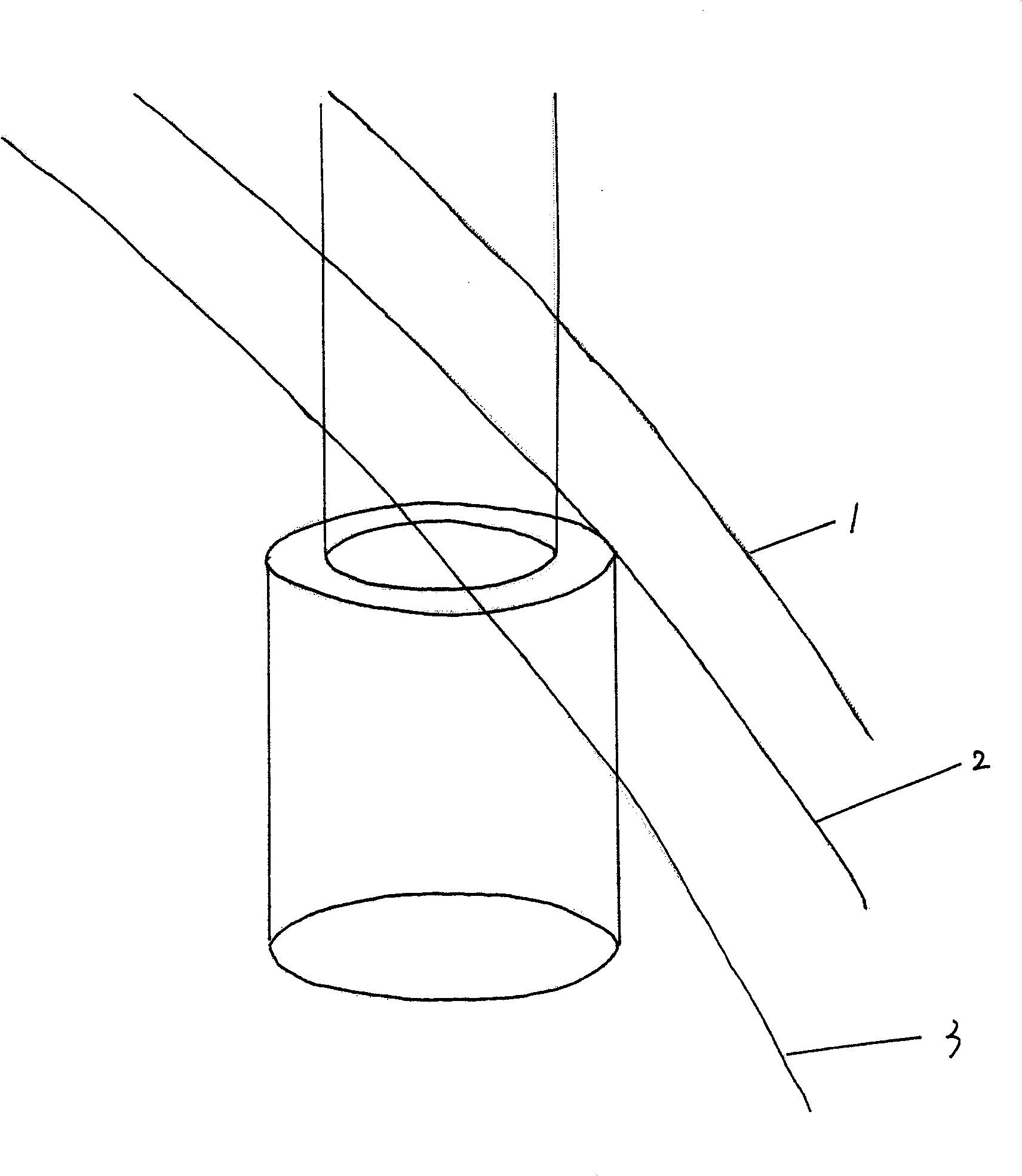

[0010] Such as figure 2 , 3 Shown: The gap of the cutting edge is generally processed by the back milling cutter, and the cyan surface is the trimming cutting edge. Compared with the sheet body, the solid body has the disadvantages of low precision, large amount of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com