Device and method for pneumatic demoulding by injection molding of micro-fluidic chip

A microfluidic chip and injection molding technology, applied in the field of microfluidic chip injection molding pneumatic demolding devices and methods, can solve the problems of affecting the bonding quality, increase the rejection rate, uneven force, etc., and achieve smooth chip surface, Improve the pass rate and improve the effect of bonding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

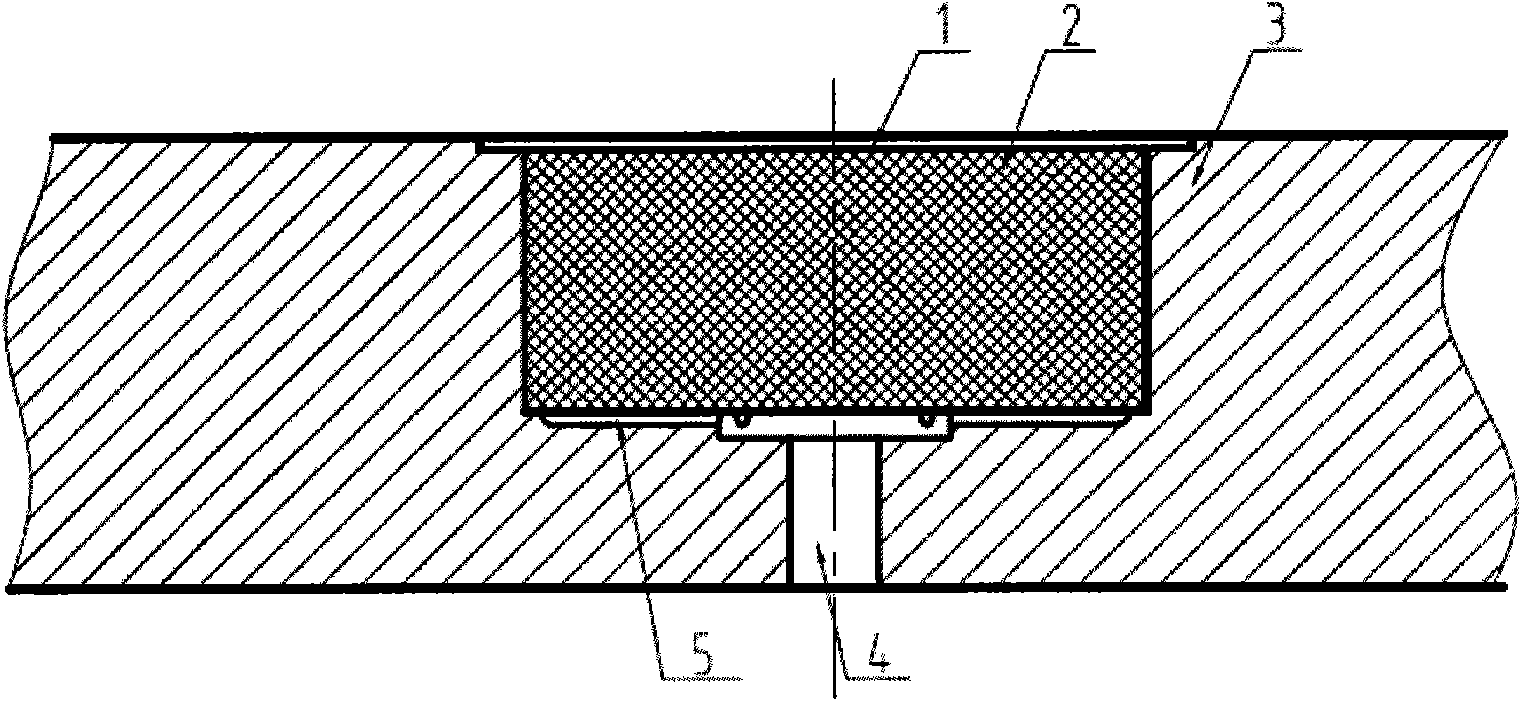

[0017] Such as figure 1 The schematic diagram of the structure of the pneumatic demoulding device and method shown, the demoulding structure includes a moving template 3, a cuboid moving mold insert 2 made of a gas-permeable material, a vent hole 4 connected to the bottom of the moving mold insert 2 and a radial Groove 5. The lower surface 1 of the cavity of the movable template 3 is provided with a mounting hole communicating with the cavity of the movable template, and the movable mold insert 2 is fixedly installed in the mounting hole, and has an interference fit with the mounting hole, and the movable mold insert 2 The end face is flush with the lower surface of the cavity of the movable template. The vent hole 4 is composed of two apertures of different sizes and is an integral structure. The radial groove 5 starts from the vent hole 4 and is radially distributed on the bottom of the installation hole opened on the lower surface 1 of the cavity of the movable template. T...

Embodiment 2

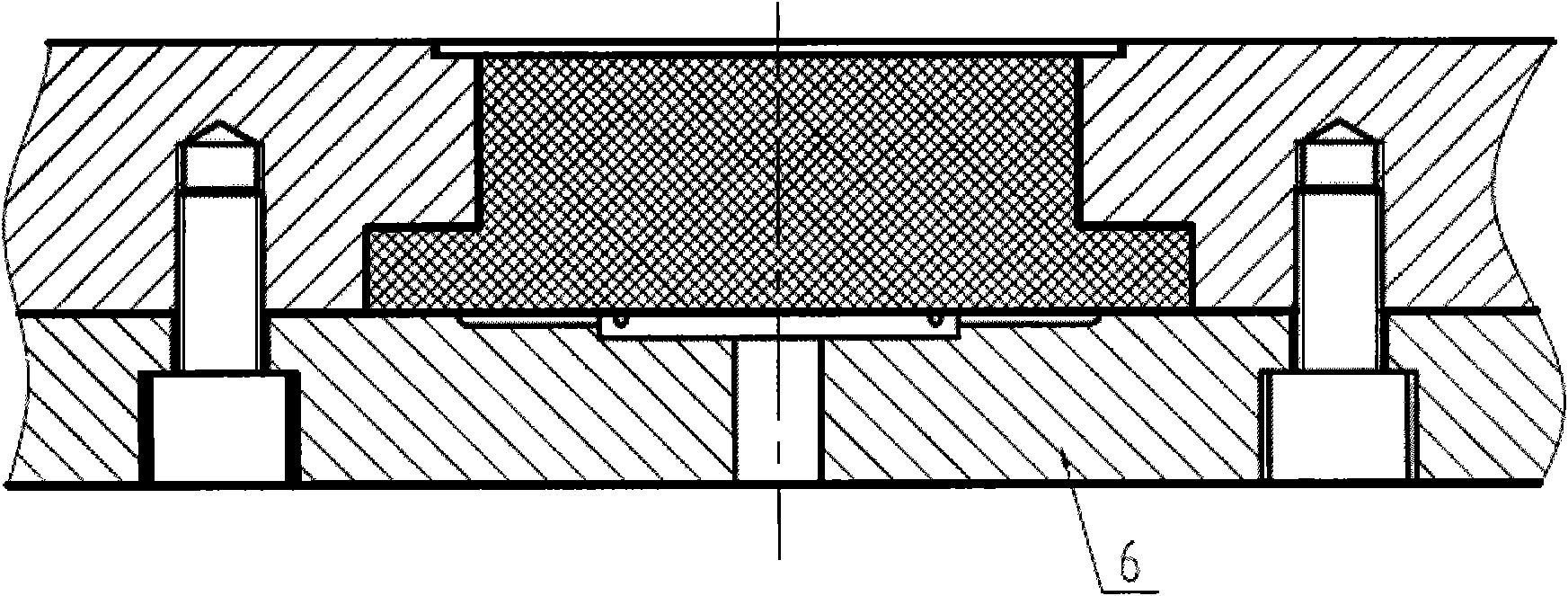

[0020] Such as figure 2 The demoulding structure shown is the embodiment 2 of the present invention. The difference from embodiment 1 is that the movable mold insert 2 made of air-permeable material is a stepped cuboid, and the movable template 3 and the movable mold are fixed by screw connection. The plate 6 is fixedly installed in the installation hole provided on the cavity lower surface 1 of the movable template 3 . In this embodiment, the movable mold insert 2 made of air-permeable material is easier to assemble and disassemble than in Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap