Bonding structure and formation method thereof

A bonding structure and bonding technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of peeling, easy bubbles, fragments, etc., and meet the requirements of reducing wafer alignment and improving Bonding quality and the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

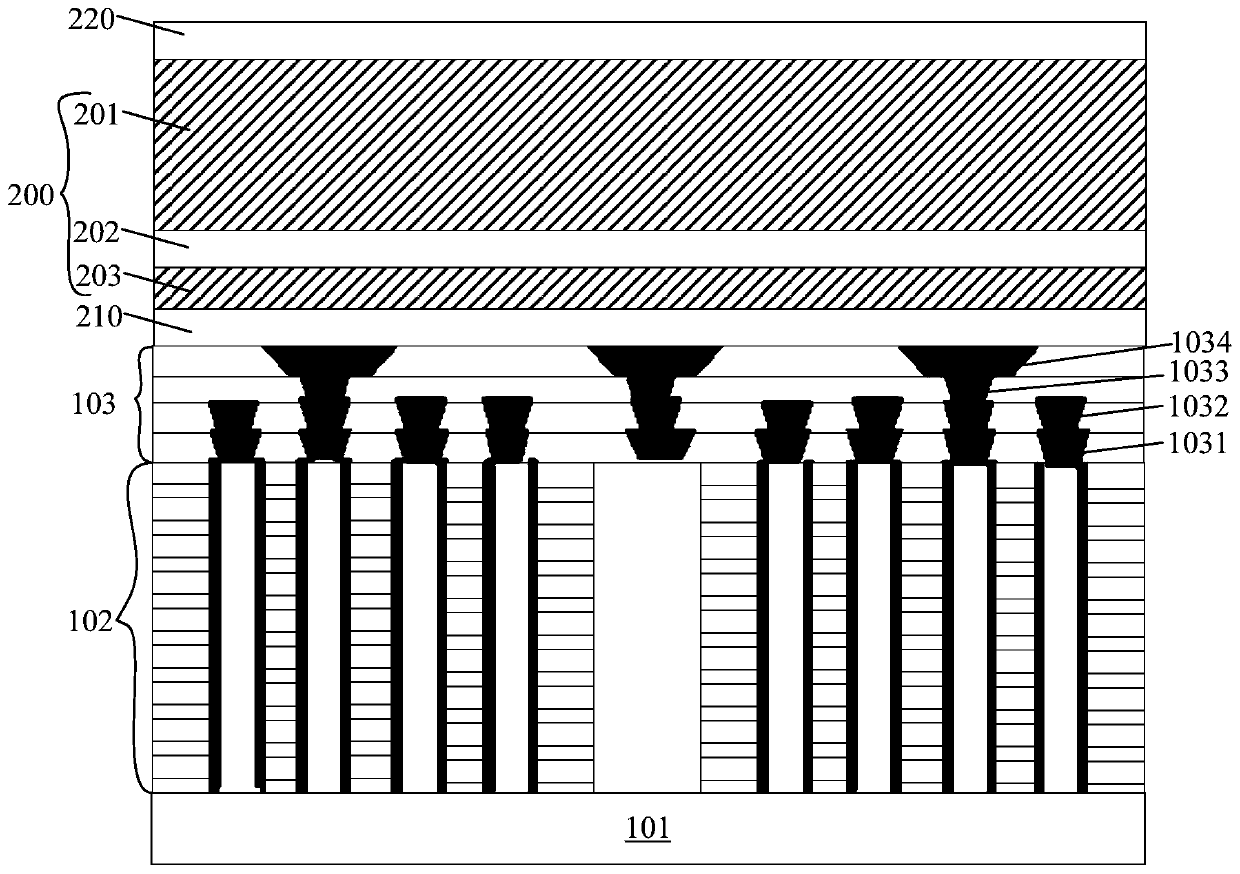

[0028] The specific implementation of the bonding structure provided by the present invention and its forming method will be described in detail below in conjunction with the accompanying drawings.

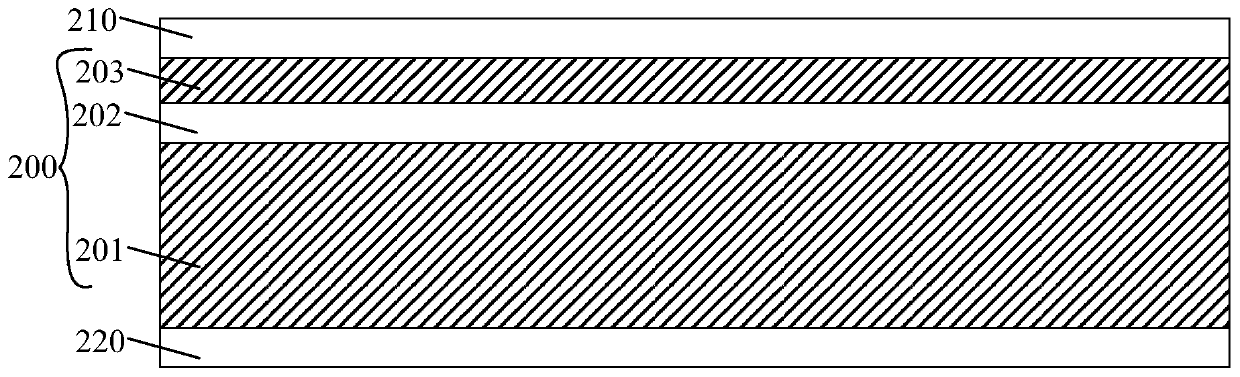

[0029] Please refer to Figure 1 to Figure 8 , is a structural schematic diagram of the formation process of the bonding structure according to a specific embodiment of the present invention.

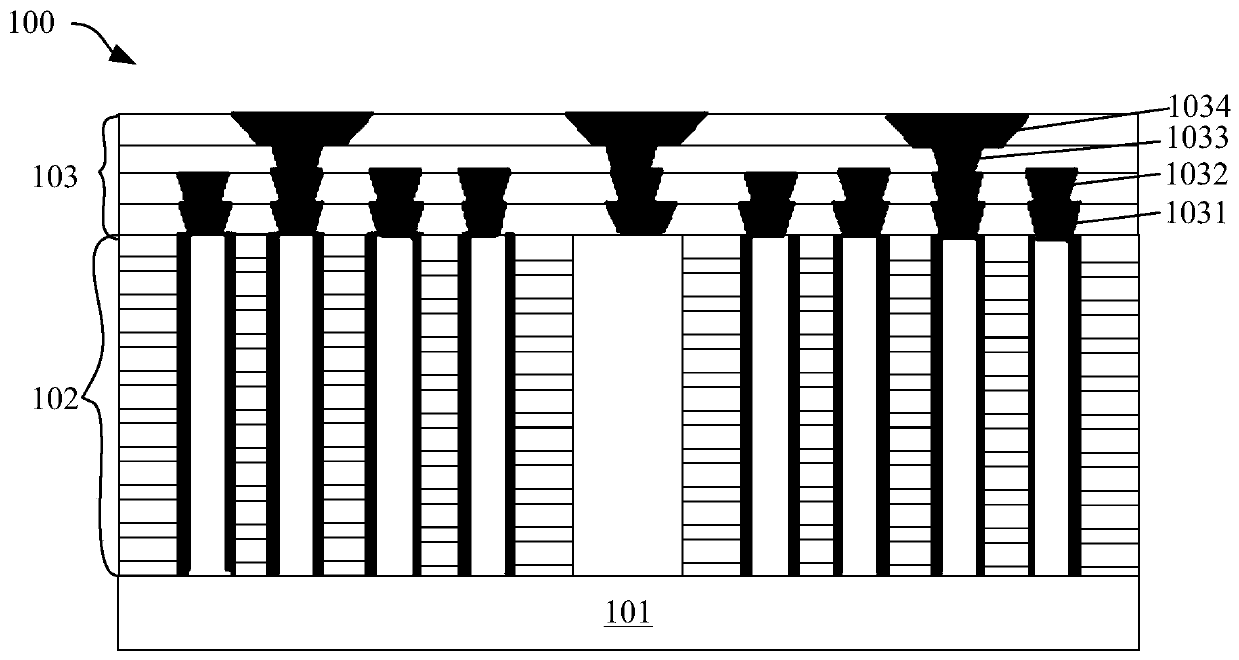

[0030] Please refer to figure 1 , providing a first substrate 100, an electrical contact portion is formed in the first substrate 100, the first substrate has a first surface and a second surface opposite to each other, and the surface of the electrical contact portion is in contact with the first substrate of the first substrate. One surface is flush.

[0031] The first substrate 100 may be a semiconductor substrate, and a dielectric layer may be formed on the semiconductor substrate, as well as semiconductor devices and interconnection structures formed in the dielectric layer.

[003...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap