All-solid-state battery

A technology of all-solid-state batteries and solid-state electrolytes, which can be used in secondary batteries, secondary battery repair/maintenance, circuits, etc., and can solve the problems of slowing down the migration speed of lithium ions, limiting the performance of lithium-ion batteries, and limiting the development of all-solid-state lithium batteries, etc. , to achieve the effect of improving the magnification characteristics and cycle performance, improving the battery life, and improving the bonding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

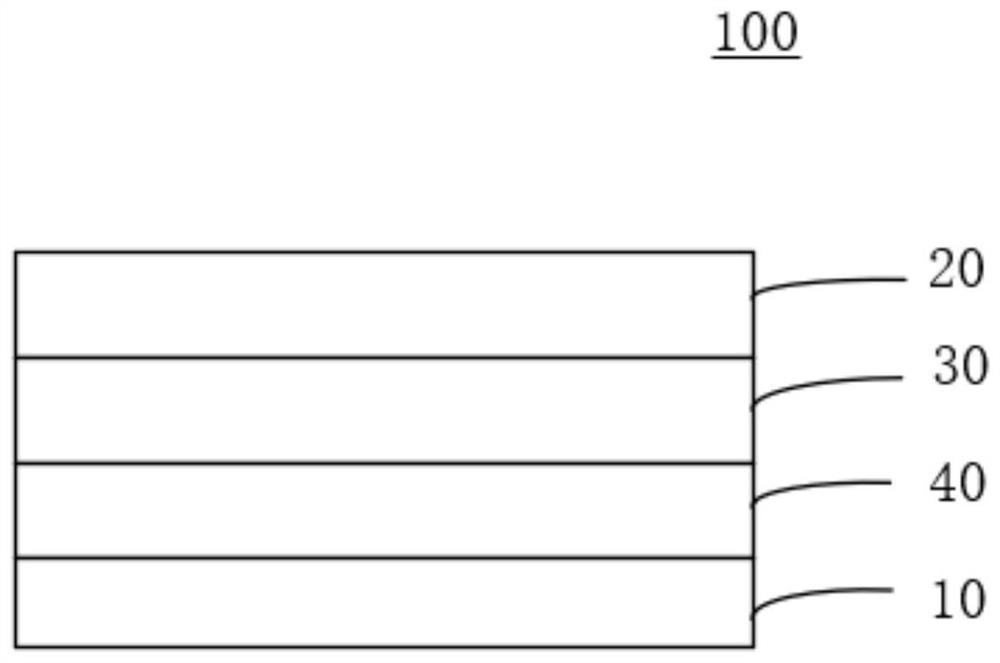

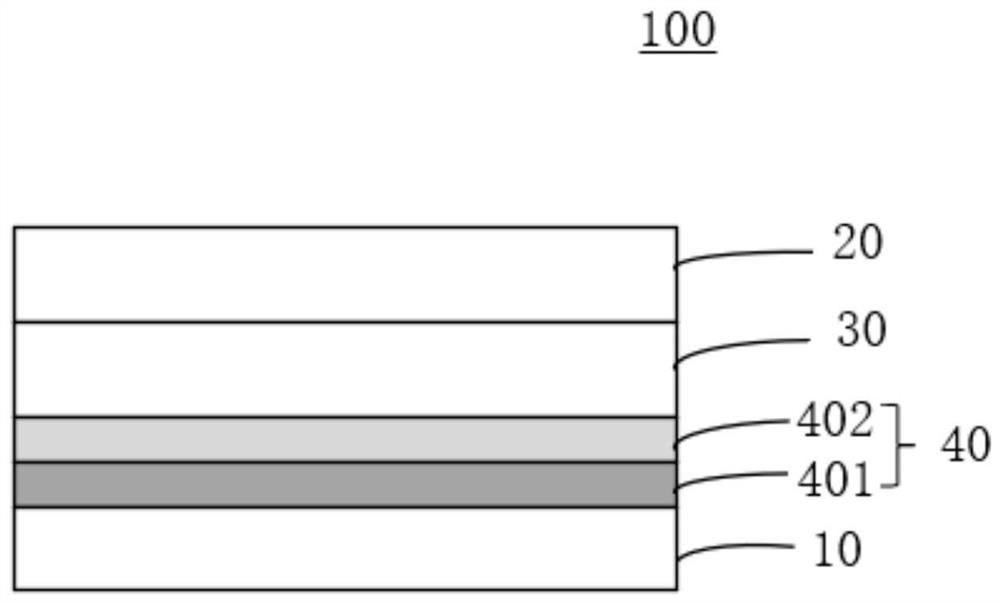

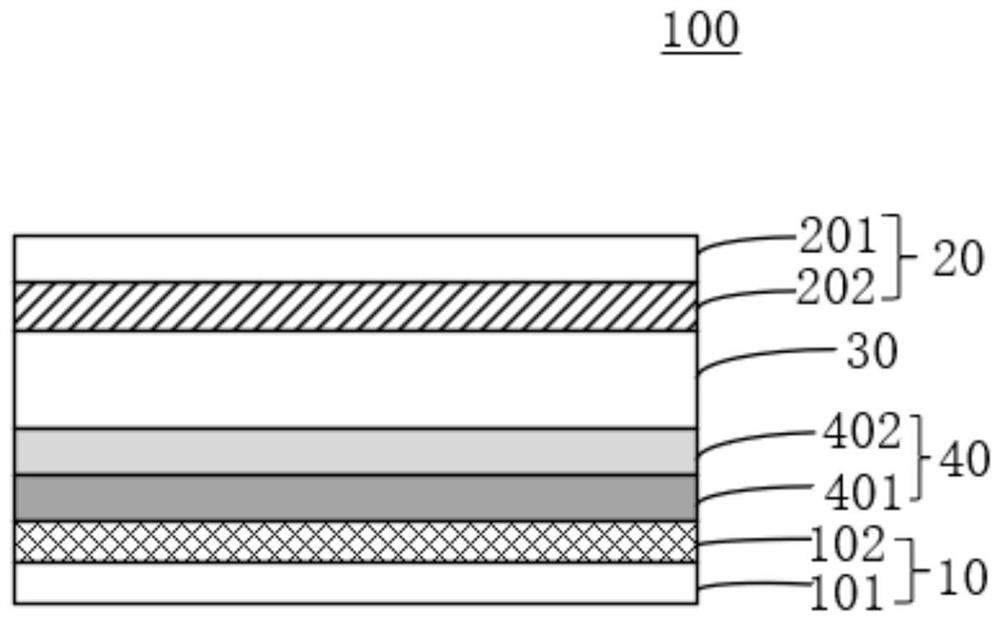

[0038] The embodiment of the present application also provides a method for preparing the above-mentioned all-solid-state battery, including the following steps:

[0039] A positive current collector layer, a positive material layer, an intermediate layer, a solid electrolyte layer, a negative material layer and a negative current collector layer are sequentially prepared on the substrate by using a magnetron sputtering method.

[0040] Wherein, the substrate may be a silicon substrate polished on one side, a mica with a smooth surface, stainless steel, a polyimide (PI) substrate, and the like. The surface cleanliness of the substrate will affect the adhesion effect and growth quality of the film on the substrate. The substrate can be cleaned before depositing the battery functional layer. The cleaning operation can be performed by ultrasonically cleaning the substrate with alcohol and acetone for 3-5 minutes. Then use high-purity nitrogen to blow off residual impurities or cl...

Embodiment 1

[0054] (1) Use alcohol and acetone to ultrasonically clean the silicon substrate polished on one side for 3-5 minutes, and then use high-purity nitrogen to blow off residual impurities or cleaning agents on the substrate surface.

[0055] (2) The Ag target of the current collector, the electrode target (NCM positive electrode, LTO negative electrode) and the electrolyte target (LiLaTiO 3 ) and the substrate were placed in the magnetron sputtering chamber. Background vacuum -4 Pa, the metal current collector was prepared by DC magnetron sputtering, and the intermediate layer, electrode and solid electrolyte layer were prepared by radio frequency magnetron sputtering. The preparation steps are as follows:

[0056] 2a. Introduce a pure Ar atmosphere, the air pressure is 0.3Pa, and prepare a positive current collector layer on the silicon substrate with a power of 70W, with a thickness of 300nm;

[0057] 2b. Introduce 0.5Pa of Ar-O 2 Mixed gas, argon-oxygen ratio Ar 2 :O 2 Th...

Embodiment 2

[0064] (1) Use alcohol and acetone to ultrasonically clean the silicon substrate polished on one side for 3-5 minutes, and then use high-purity nitrogen to blow off residual impurities or cleaning agents on the substrate surface.

[0065] (2) The Ag target of the current collector, the electrode target (NCM positive electrode) and the electrolyte target (LiLaTiO 3 ) and the substrate were placed in the magnetron sputtering chamber. Background vacuum -4 Pa, the metal current collector was prepared by DC magnetron sputtering, and the intermediate layer, electrode and solid electrolyte layer were prepared by radio frequency magnetron sputtering. The preparation steps are as follows:

[0066] 2a. Introduce a pure Ar atmosphere, the air pressure is 0.3Pa, and a positive electrode current collector film is prepared on the silicon substrate with a power of 70W, with a thickness of 300nm;

[0067] 2b. Introduce 0.5Pa of Ar-O 2 Mixed gas, argon-oxygen ratio Ar 2 :O 2 The ratio is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap