Rubber-tyred container gantry crane automatic electricity getting system

A technology for container and gantry cranes is applied in the field of automatic power-taking systems for tire-mounted container gantry cranes, which can solve the problems of inability to automatically connect and disconnect safety slide lines and their tracks for power-taking, easy deviation, etc., so as to reduce maintenance workload, The effect of large access window and automatic ice, snow and frost removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

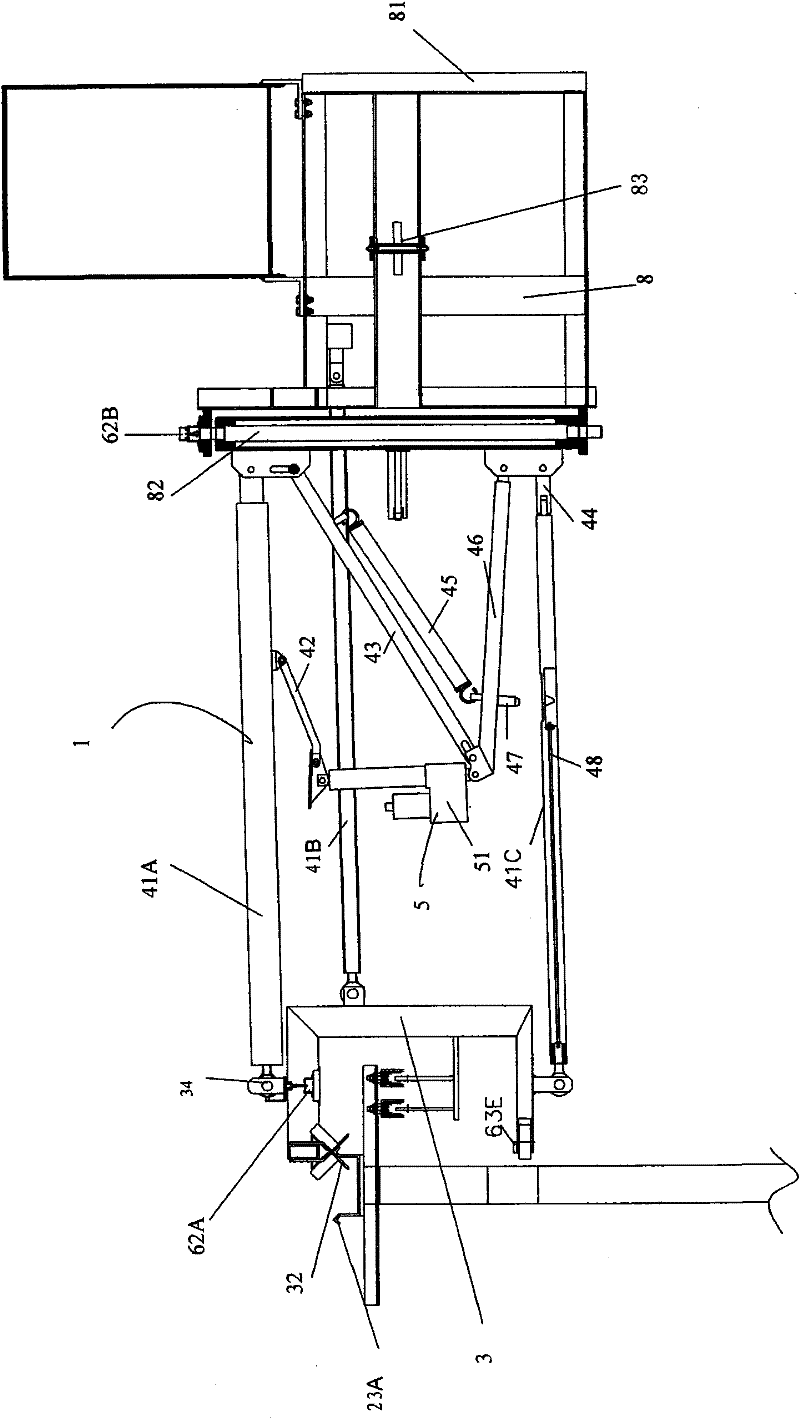

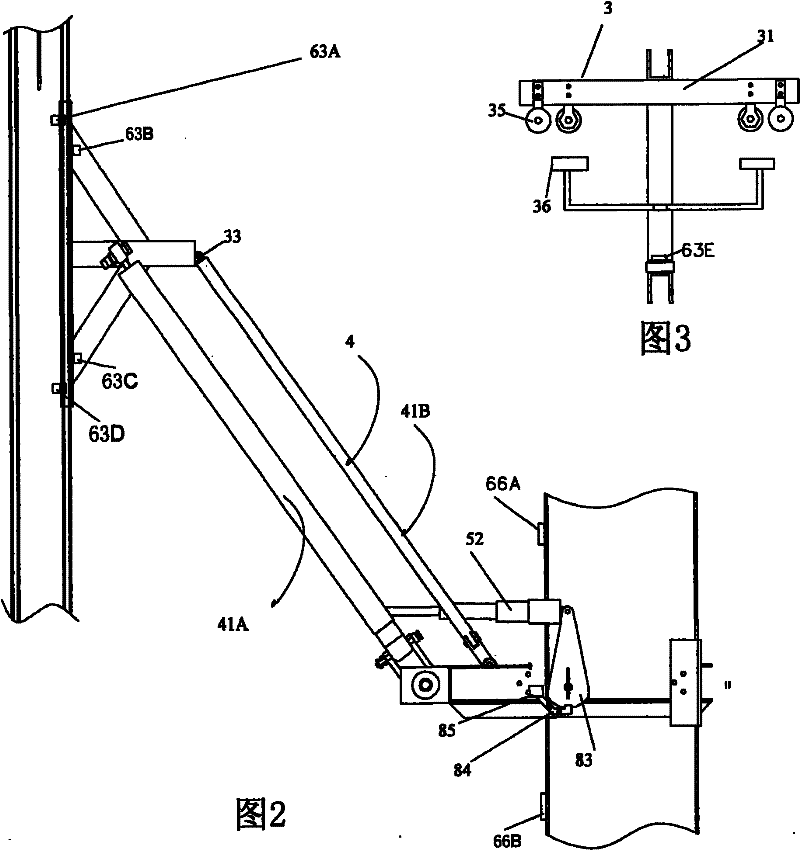

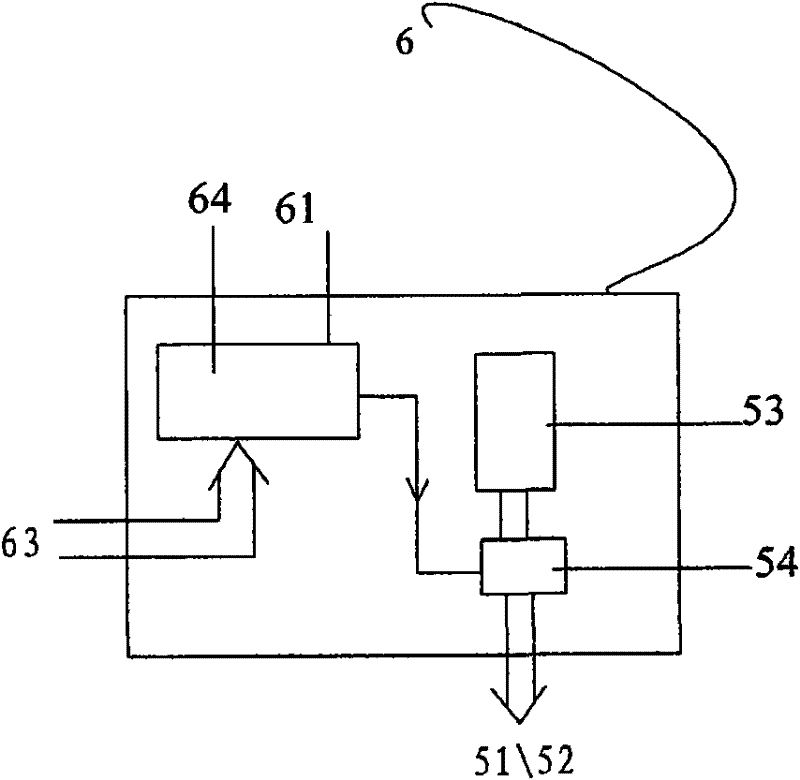

[0028] Such as Figure 1 to Figure 5 As shown, the description of the icon numbers is as follows:

[0029] Electricity taking device 1, sliding wire track bracket 2, access / disengagement section 21, first track 23A, second track 23B, first detection board 24A, second detection board 24B, baffle plate 25, support column 26,

[0030] Power-taking section 22, first track 23A, second track 23B, power-taking end detection board 27, slide wire access locator 28,

[0031] Power-taking trolley 3, main frame 31, track locator 32, elastic connector 33, joint bearing 34, walking wheels 35, power-taking brush 36,

[0032] Connection mechanism 4, first connecting rod 41A, second connecting rod 41B, third connecting rod 41C, floating connecting rod 42, pull rod 43, spring 45, support rod 46, pin 47, conversion joint 44, positioning connecting rod 48,

[...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap