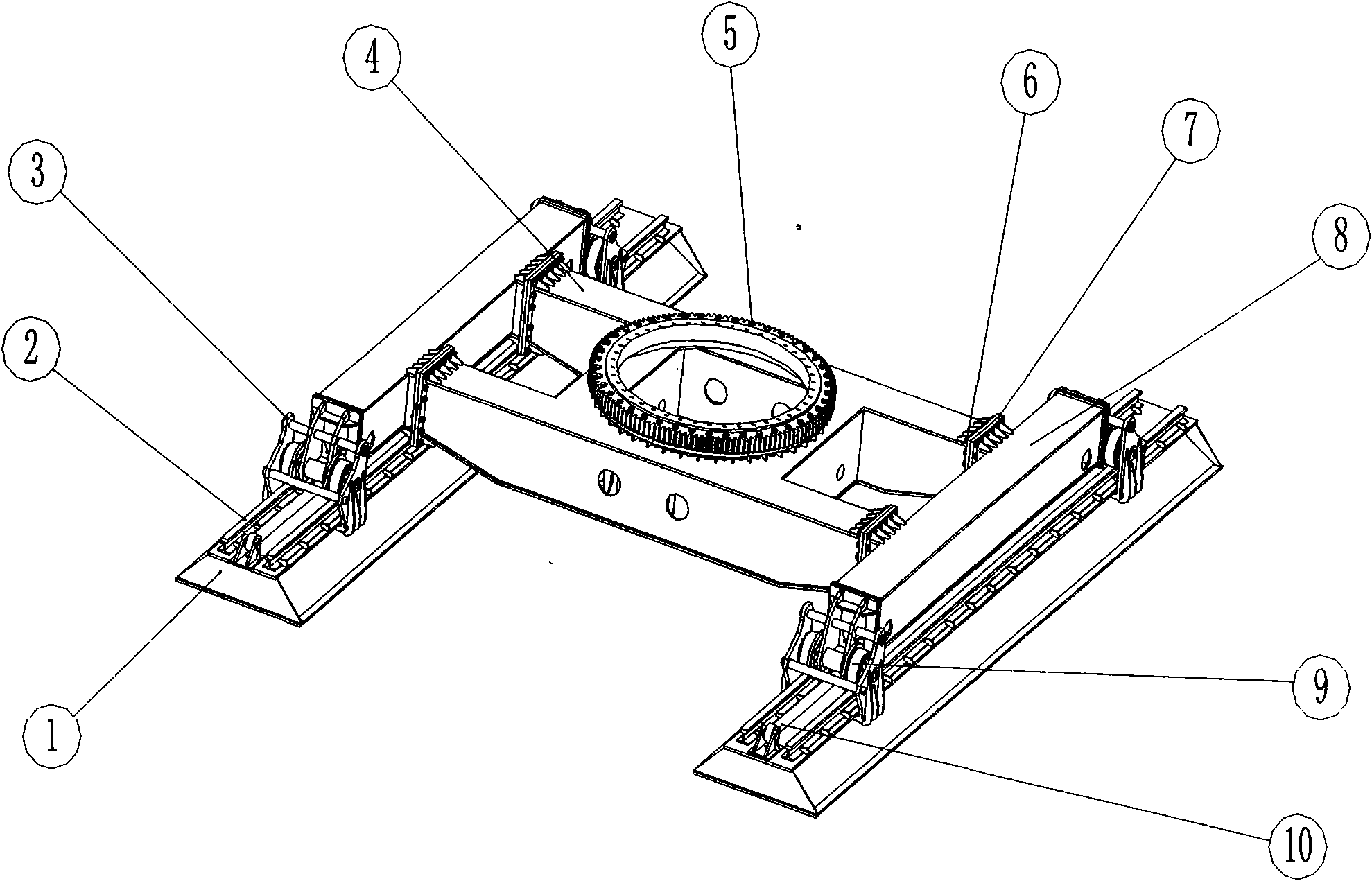

Heavy hydraulic walking chassis

A walking chassis and walking-type technology, which is applied to drilling equipment, drilling equipment and methods, and earthwork drilling and production, and can solve the problems of increasing the supporting surface of equipment and not exceeding the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The chassis is mainly used in large-scale long auger drilling machines as an important structure for loading and transportation, supporting travel and rotary positioning. When loading the vehicle, in order to reduce the loading width, remove the connecting fastener ⑥ to separate the H-shaped beam ④ from the supporting beam ⑧ of the trolley. The parts ①②③⑧⑨⑩ can be transported in bulk, while the H-shaped beam and the upper part of the equipment can be transported in bulk. Transport together so that the chassis section does not exceed the transport width. In order to increase the grounding area during construction, the H-shaped girder ④ and the trolley support beam ⑧ are butted through the connecting flange ⑦, and then connected with the connecting fastener ⑥. After installing parts ①②③⑨⑩ and other parts, the grounding area and supporting span of the chassis of the whole machine can be increased. When walking in a straight line during the construction process, the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com