Blade capable of weakening shock strength of transonic speed turbine

A technology of shock wave intensity and transonic speed, which is applied in the direction of blade support components, engine components, machines/engines, etc., can solve the unstable flow field of the cascade flow field of the turbine engine, weaken the shock wave intensity of the transonic turbine, and the turbine engine Noise and other problems, to achieve the effect of weakening transmission, stable flow, and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

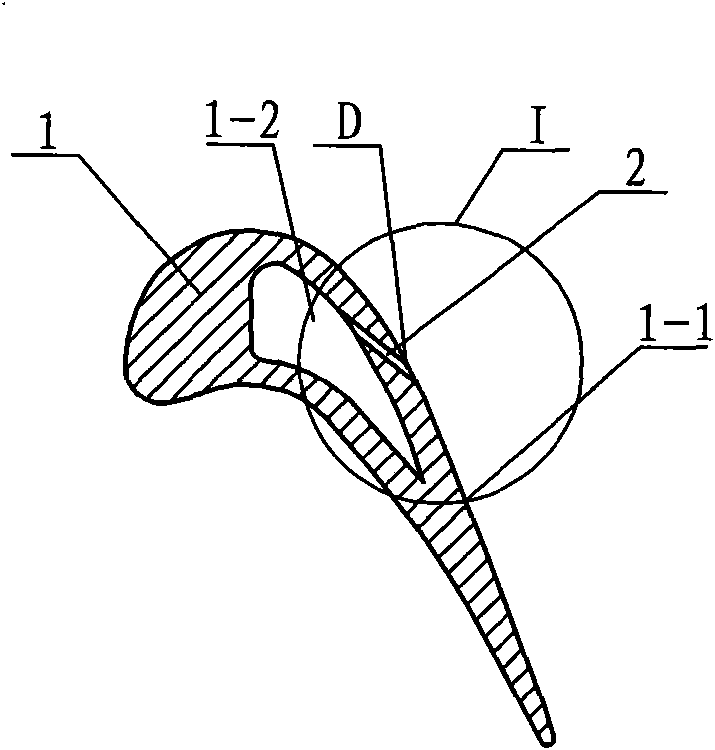

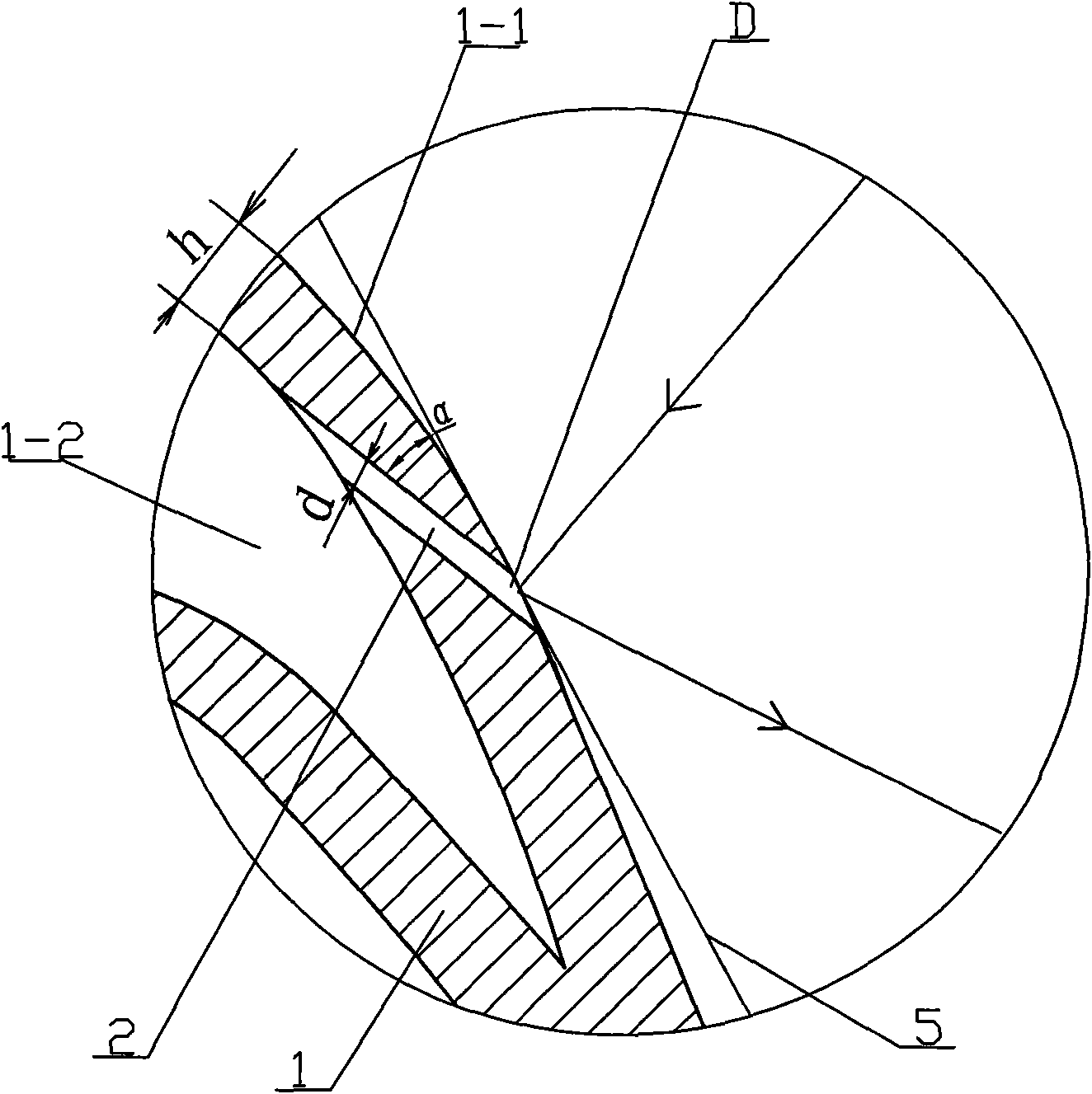

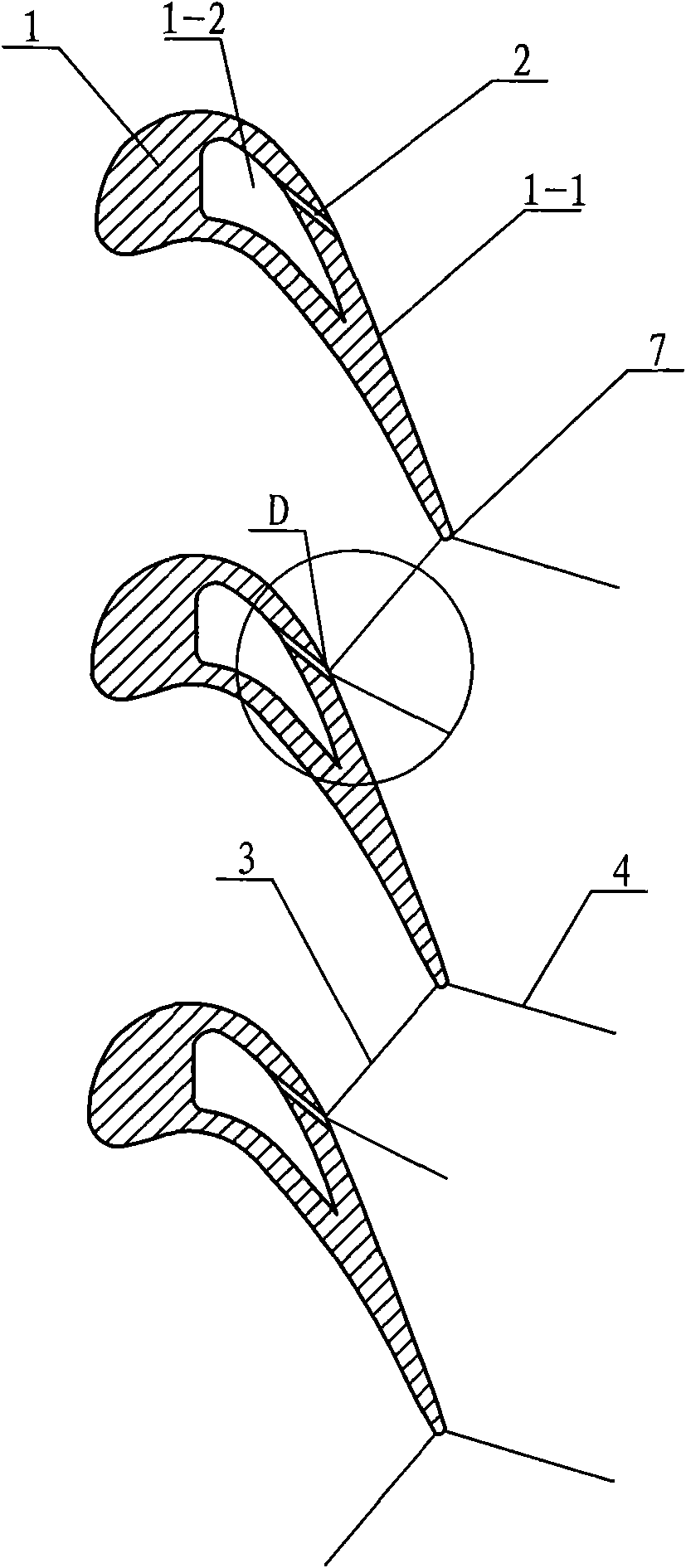

[0007] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, at least one cold air injection hole 2 communicating with the inner cavity 1-2 is provided on the shock refraction ray formed by the combination of shock refraction points on the suction surface 1-1 of the blade 1 in this embodiment. The air flow from the compressor enters the blade flow field through the cold air nozzle 2 from the inner cavity, forming a cold air jet, which changes the local pressure difference in the propagation direction of the shock wave pressure surface branch at the trailing edge 7, and weakens the shock wave pressure surface branch 3 and the propagation strength of branch 4 of the suction surface, as image 3 As shown, the shock wave strength of the transonic turbine is weakened, the flow of the cascade flow field is significantly improved, and the energy loss is reduced.

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 2 The present embodiment will be described. The included angle α between the cold air injection hole 2 and the tangent 5 of the suction surface in this embodiment is 20°-160°. The size of the included angle α can be adjusted according to the incident direction of the shock wave.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 2 The present embodiment will be described. The diameter d of the cool air injection hole 2 in the present embodiment is 0.1 to 5 times the thickness h of the blade wall surface. The diameter of the cold air injection hole 2 can be changed according to the magnitude of the shock wave intensity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com