On-line acquisition method for plasticity coefficient of rolled piece during rolling of medium plate

A rolling process and acquisition method technology, applied in the rolling field, can solve the problems of large difference between tangent slope and average slope, inaccurate control of system thickness, large acquisition error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

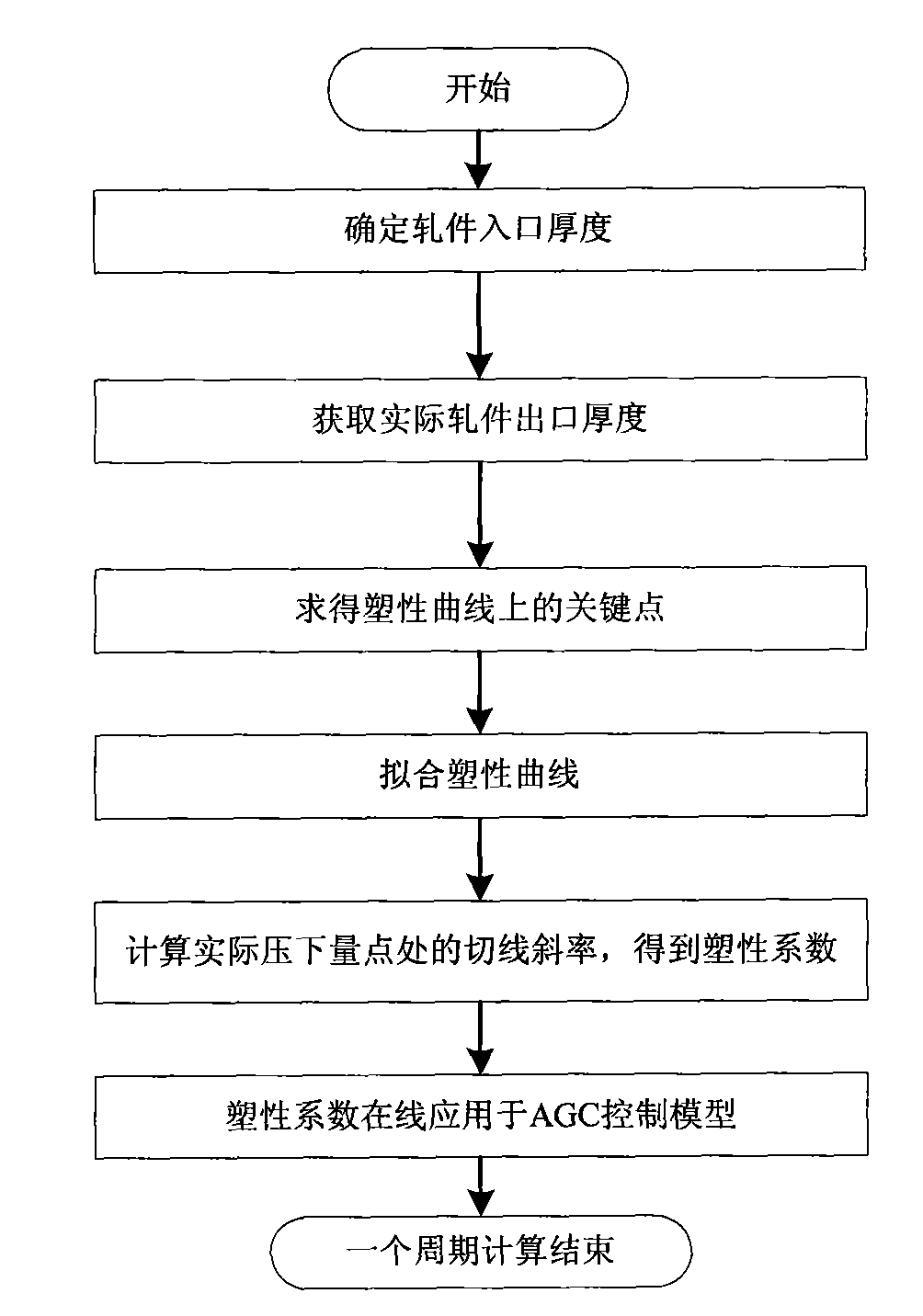

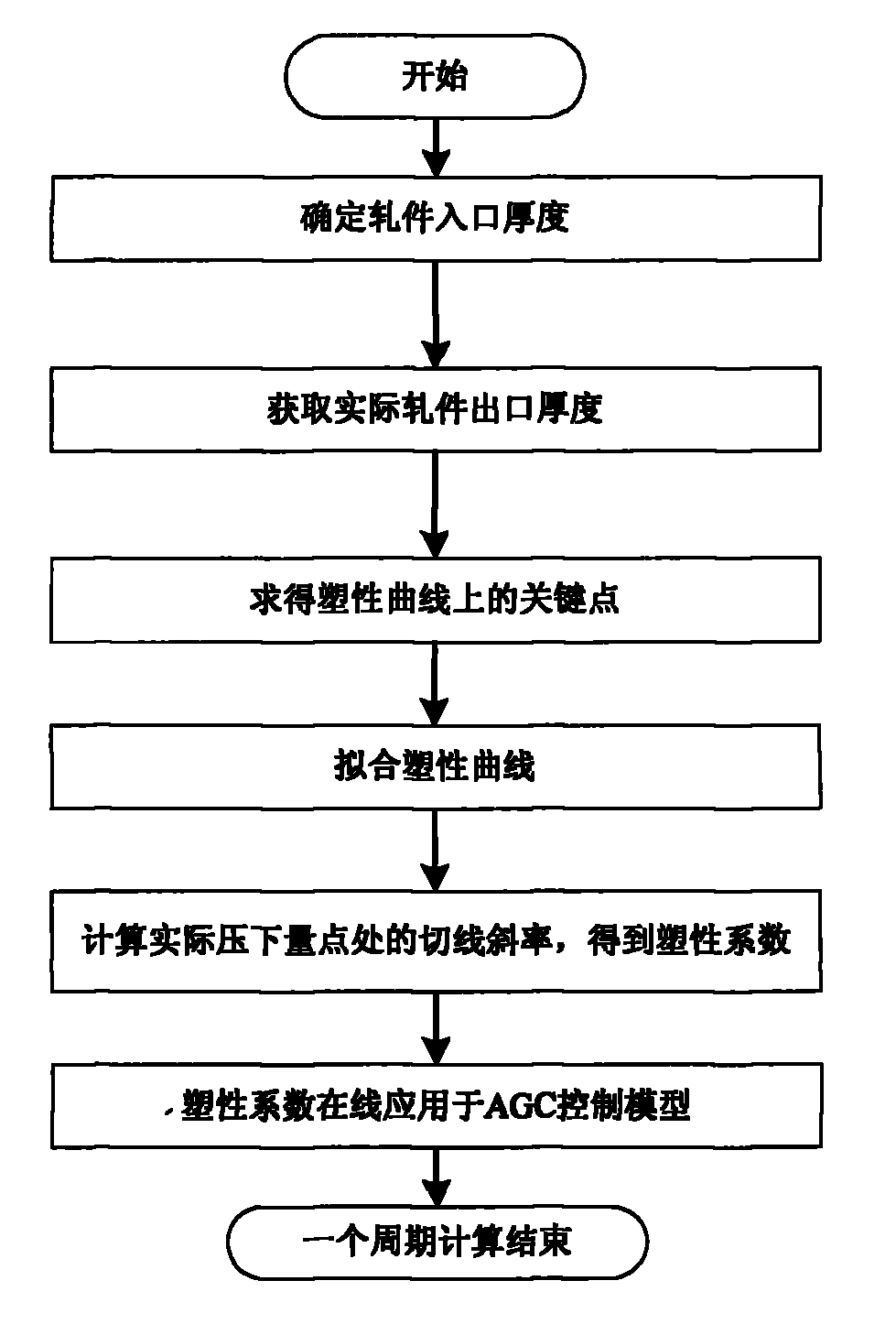

Method used

Image

Examples

Embodiment Construction

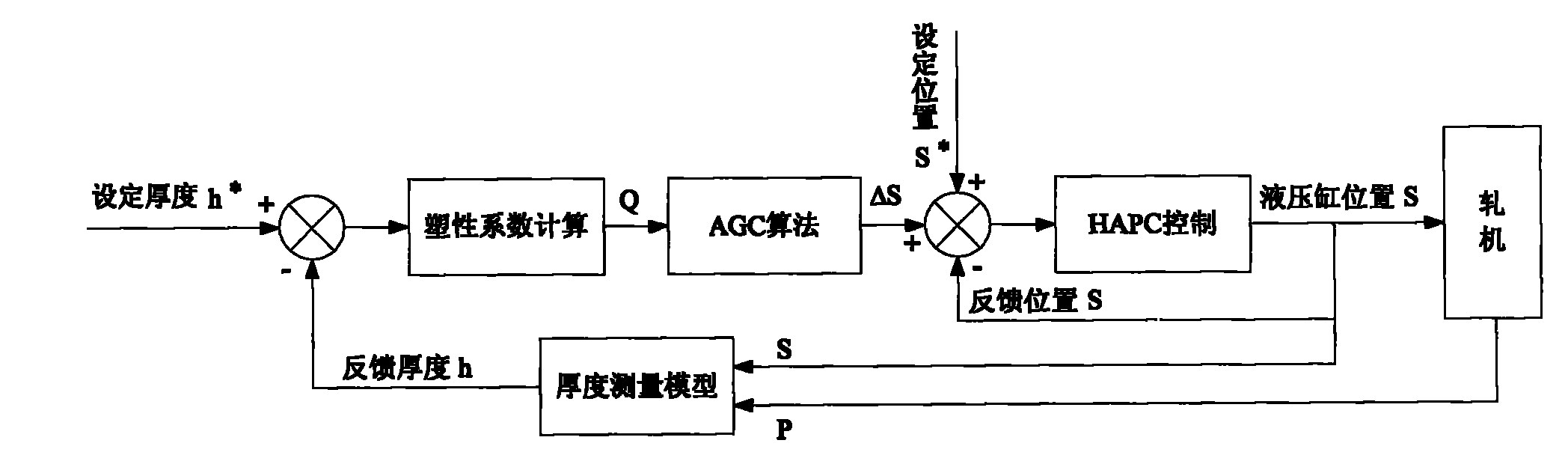

[0069] The detailed process of an online acquisition method for the plasticity coefficient of a rolled piece during the medium and heavy plate rolling process of the present invention will be described in conjunction with an embodiment. A block diagram of AGC control for the plastic coefficient of the rolled piece in the rolling process of medium and heavy plates figure 2 shown.

[0070] The present embodiment selects the Q235 steel type, and the parameters are as follows:

[0071] ·Steel type: Q235

[0072] ·Blank specification: 220mm×1600mm×2810mm

[0073] ·Finished size: 14mm×2120mm

[0074] ·Out of furnace temperature: 1100℃

[0075] ·Rolling pass: 15 passes

[0076] ·Rolling mill rigidity M: 8000KN / mm

[0077] ·Clear rolling force: 18560KN / mm

[0078] ·Deformation resistance parameters: a 3 = 0.000027, a 4 =0.25381

[0079] The rolling schedule is set as shown in Table 1.

[0080] Table 1 Rolling Schedule

[0081]

[0082]

[0083] The present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com