Connector

A technology of connectors and connecting terminals, which is applied in the direction of connection, parts of connection devices, electrical components, etc. It can solve the problems of plastic deformation of the elastic part 34, falling of the operating rod, and inability to connect, etc., and achieves prevention of plastic deformation and positional accuracy. Improvement, contact reliability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Next, an embodiment of the present invention will be described with reference to FIGS. 1 to 13 .

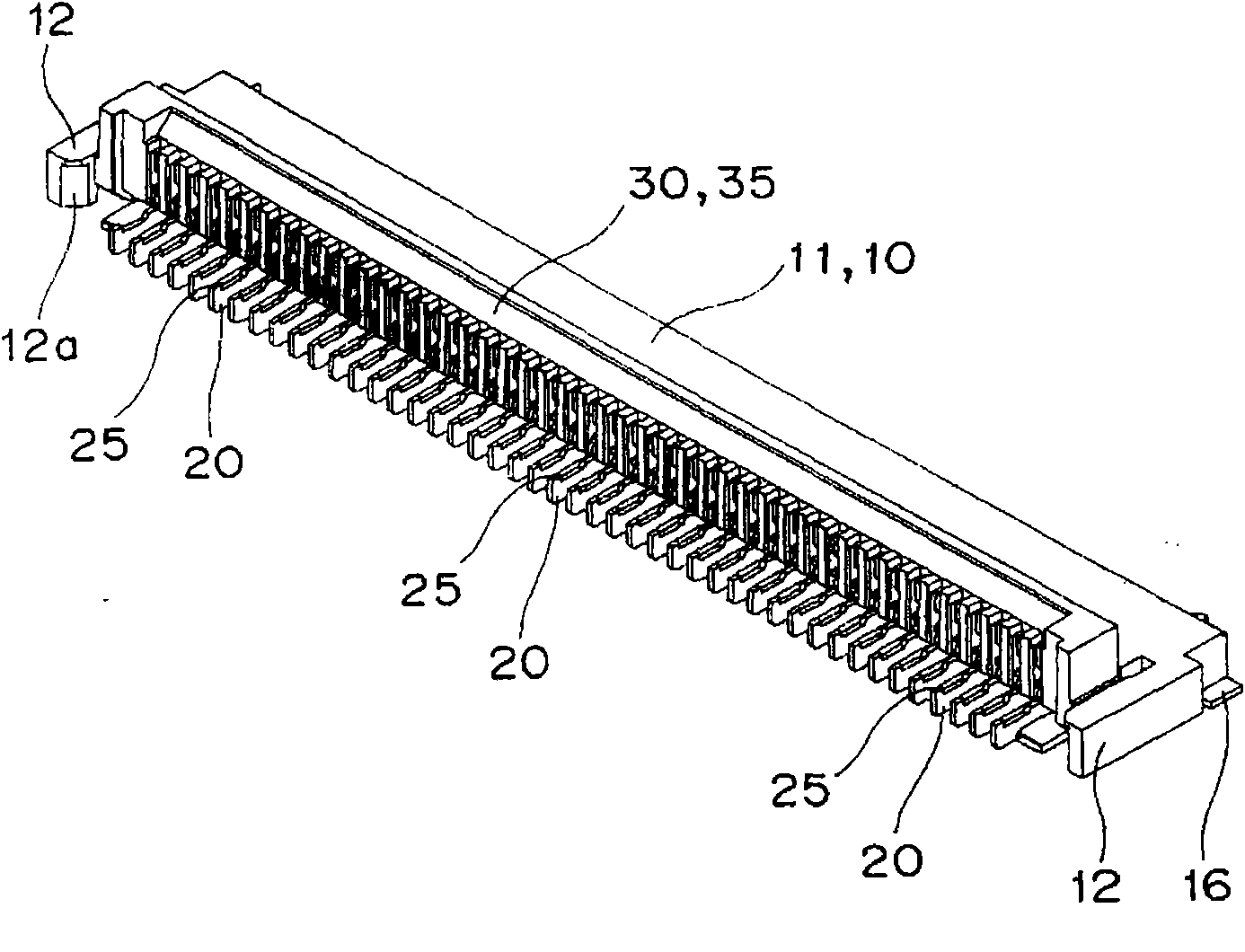

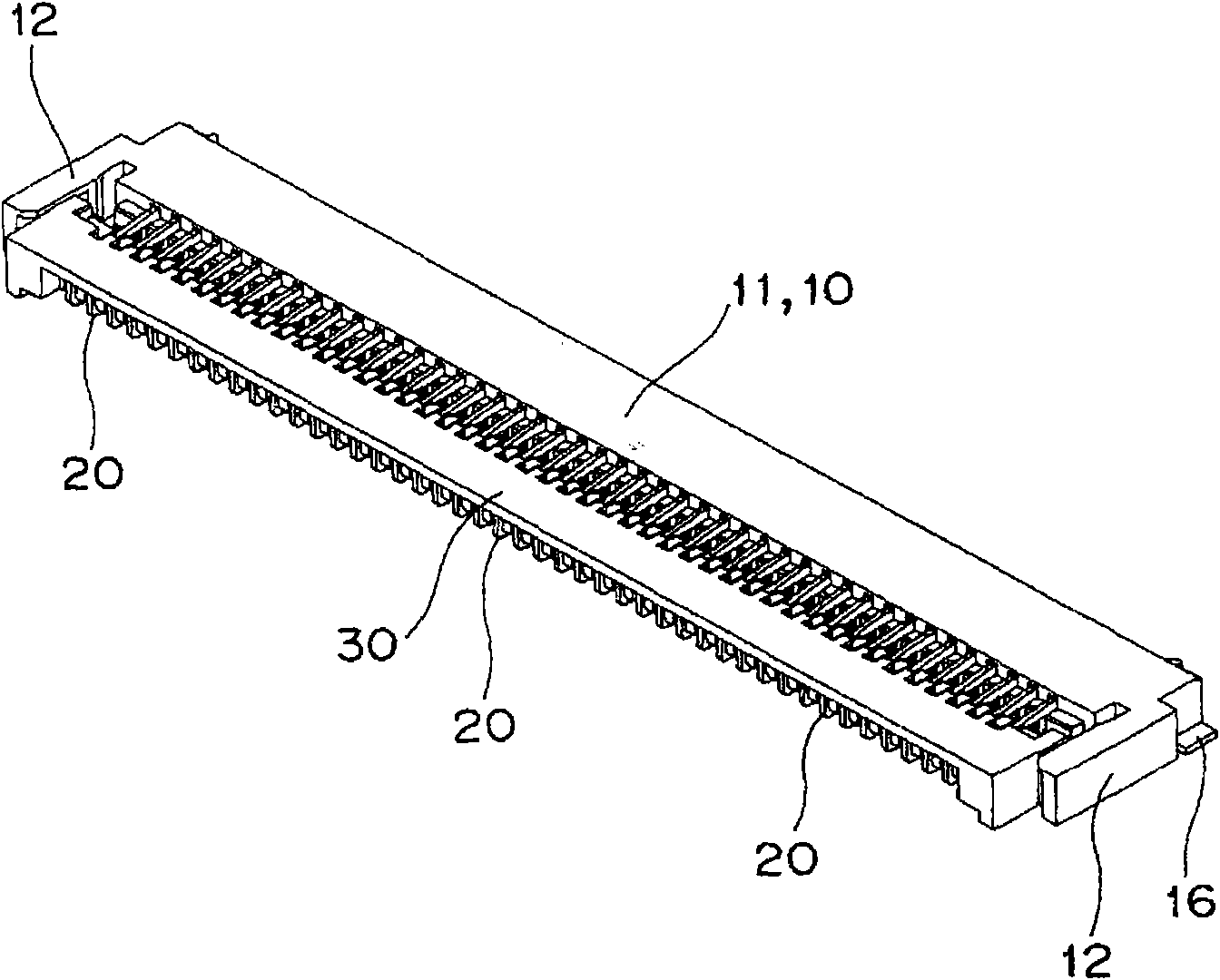

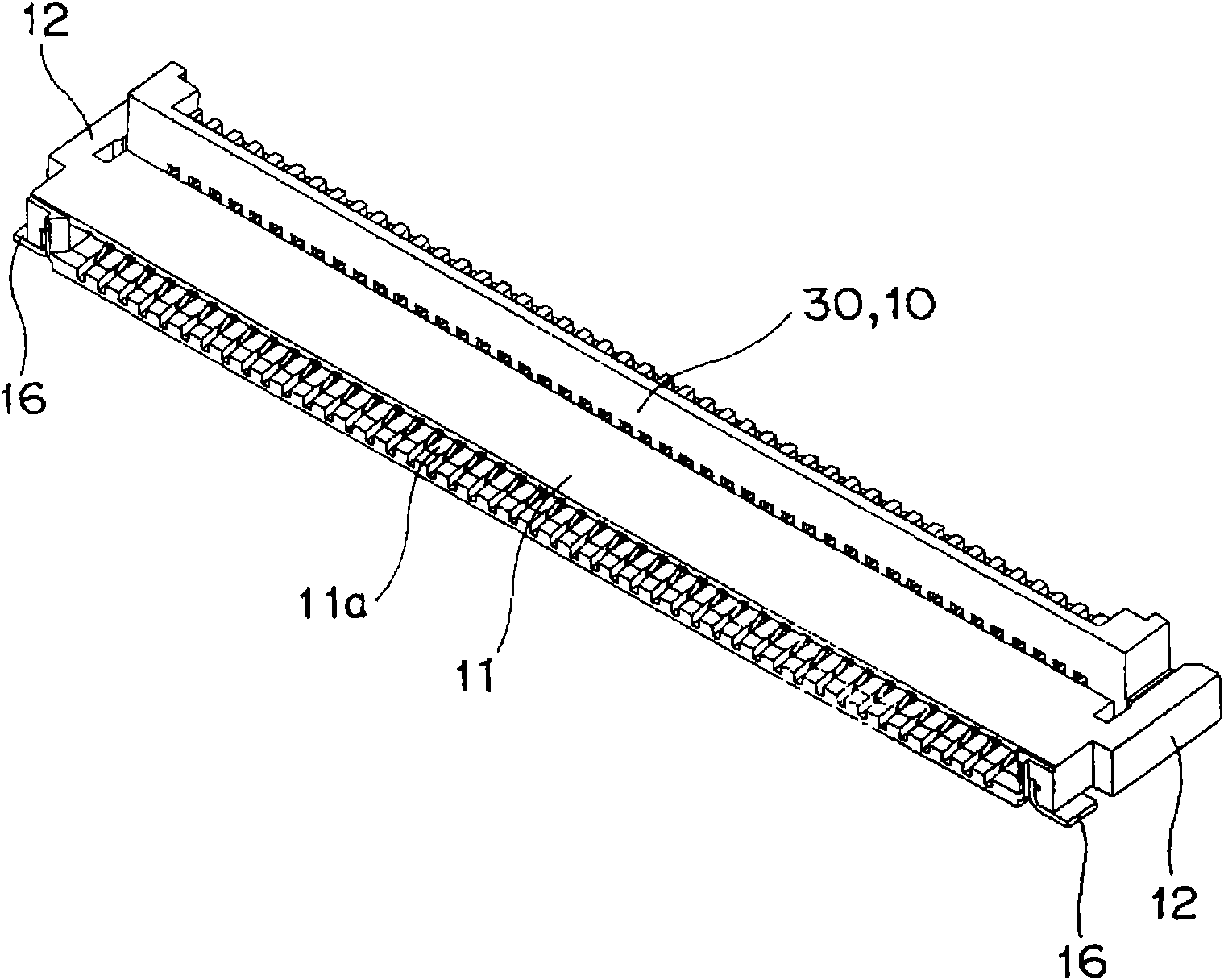

[0069] Figure 1~ image 3 As shown, the connector 10 of the first embodiment is roughly composed of a base 11, a connection terminal 20, and an operating lever 30, and is detachably connected to a flexible printed circuit board (FPC) 40 (FIGS. 4 and 5).

[0070]As shown in Figure 6 (A) and (B), the base 11 respectively extends from one side edge of the end surface of both sides to the back side in parallel with elastic arms 12, 12, and is arranged side by side with a predetermined interval. Through the insertion hole 13 on the front.

[0071] In addition, as shown in FIG. 6(A), on the inward surface of the elastic arm portion 12, a guiding tapered surface 12a is formed on the front edge thereof, and a shaft support portion 12b is formed on the inner side thereof. In addition, the base 11 extends a guide plate 14 from the lower edge of the back surface between the elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com