Interdental space direct measurement and oral cavity orthodontics micro-implant positioning implantation method

A unit of measurement, oral cavity technology, applied in implantology, medical science, dentistry, etc., can solve problems such as the inability to immediately determine the space between two teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

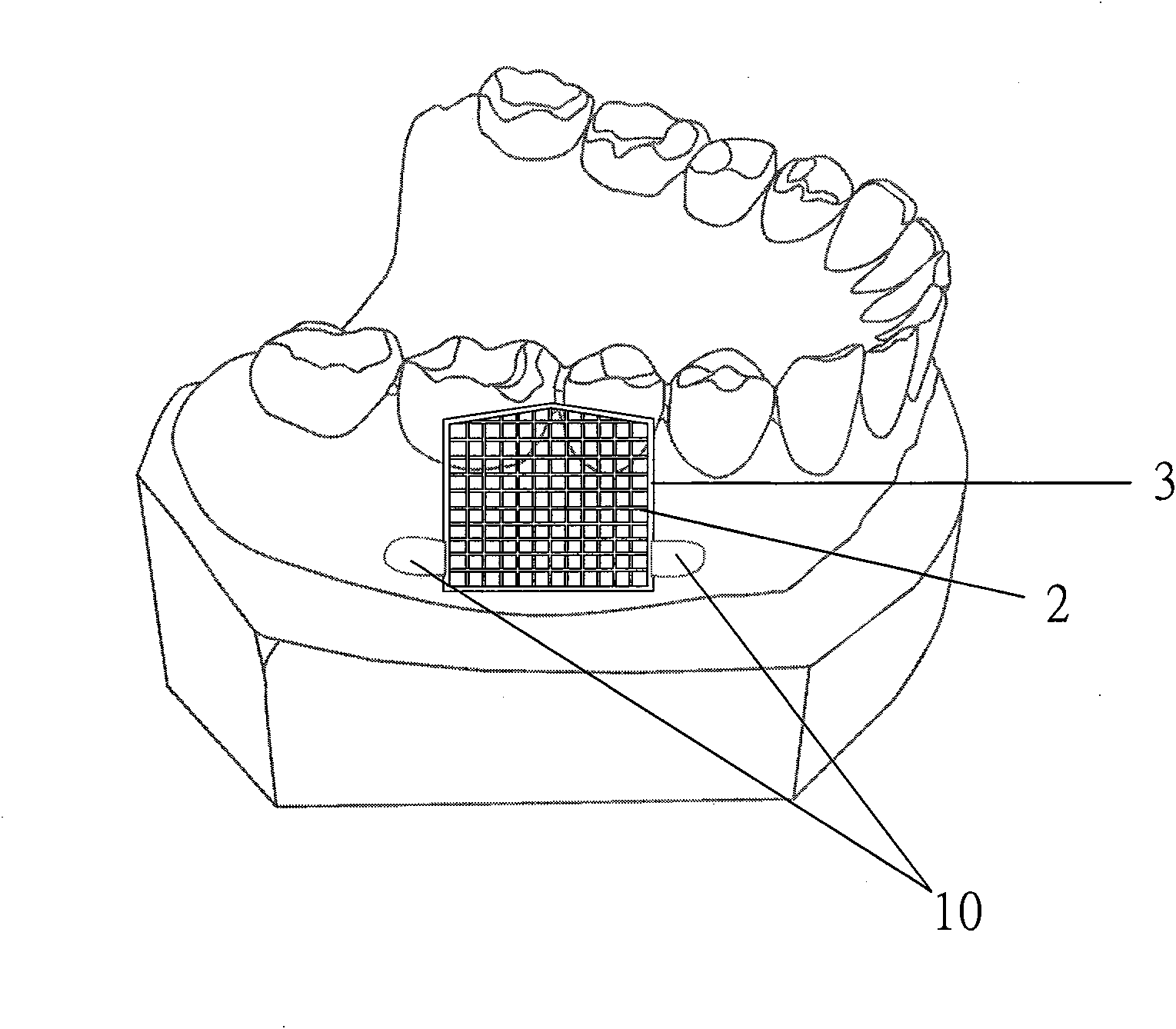

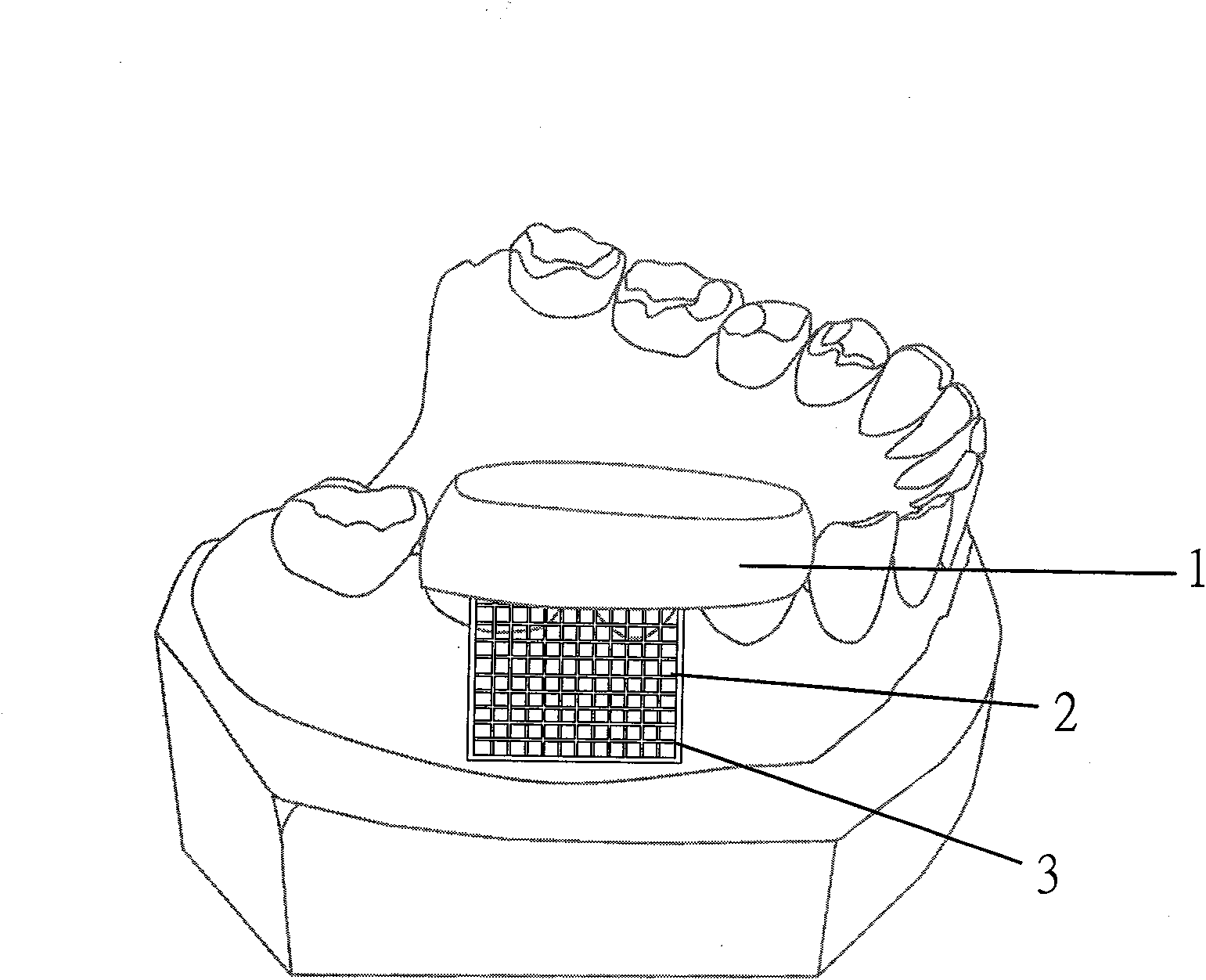

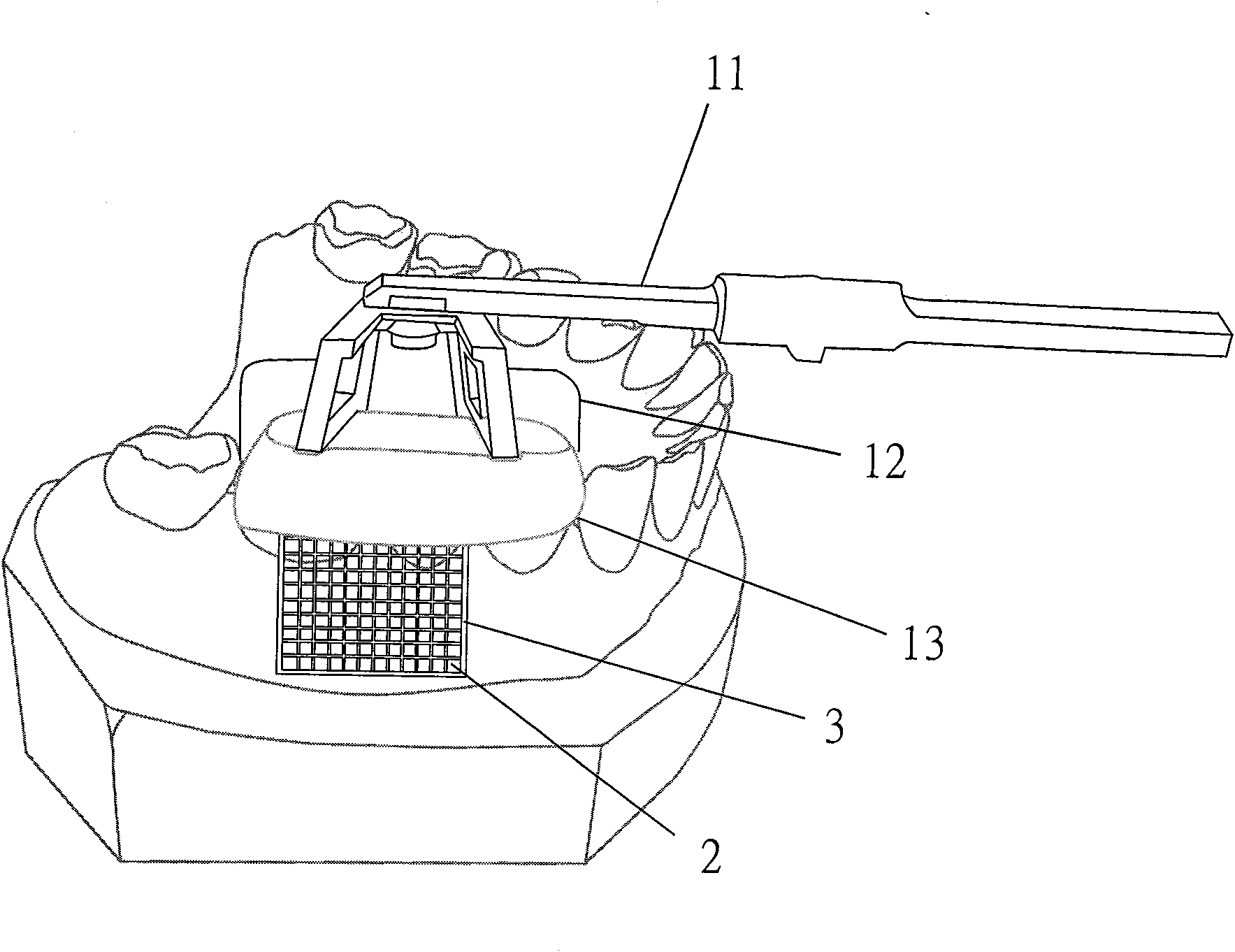

[0060] 1. Indirect method: Firstly, on the patient's working plaster model, determine the location where the orthodontic micro-implant is to be implanted, and the diameter of the micro-implant. Here is an example of implanting a micro-implant with a diameter of 1.2mm in the lower right of the patient. Between the first permanent molars and the second premolars, firstly select a three-dimensional network structure with an appropriate size and a basic measurement position, for example, the basic measurement unit is 0.7mm, and fine-tune the shape of this structure so that it can be closely attached to the The shape of the gums varies from person to person (such as figure 1 ) and then fixed on the gingiva of the plaster model with soft wax, the length of which should not irritate the oral mucosa and the mucous membrane of the floor of the mouth.

[0061] Find an x-ray film holder (x-ray Holder) that will be used for X-ray parallel irradiation in the future, and use a pencil to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com