Manufacturing method of intermateable plug-in type steel pipe pole tower

A manufacturing method and technology of steel pipes, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of reducing construction strength, construction trouble, and inability to realize batch mutual matching, etc., and achieve the effect of reducing construction strength and facilitating construction

Inactive Publication Date: 2011-01-05

ZHEJIANG SHENGDA STEEL TOWER +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to overcome the shortcomings of the existing plug-in steel pipe towers that cannot realize batch interfit and troublesome construction, the present invention provides an interfit plug-in steel pipe tower that can realize batch interfit, reduce construction strength, and facilitate construction. production method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

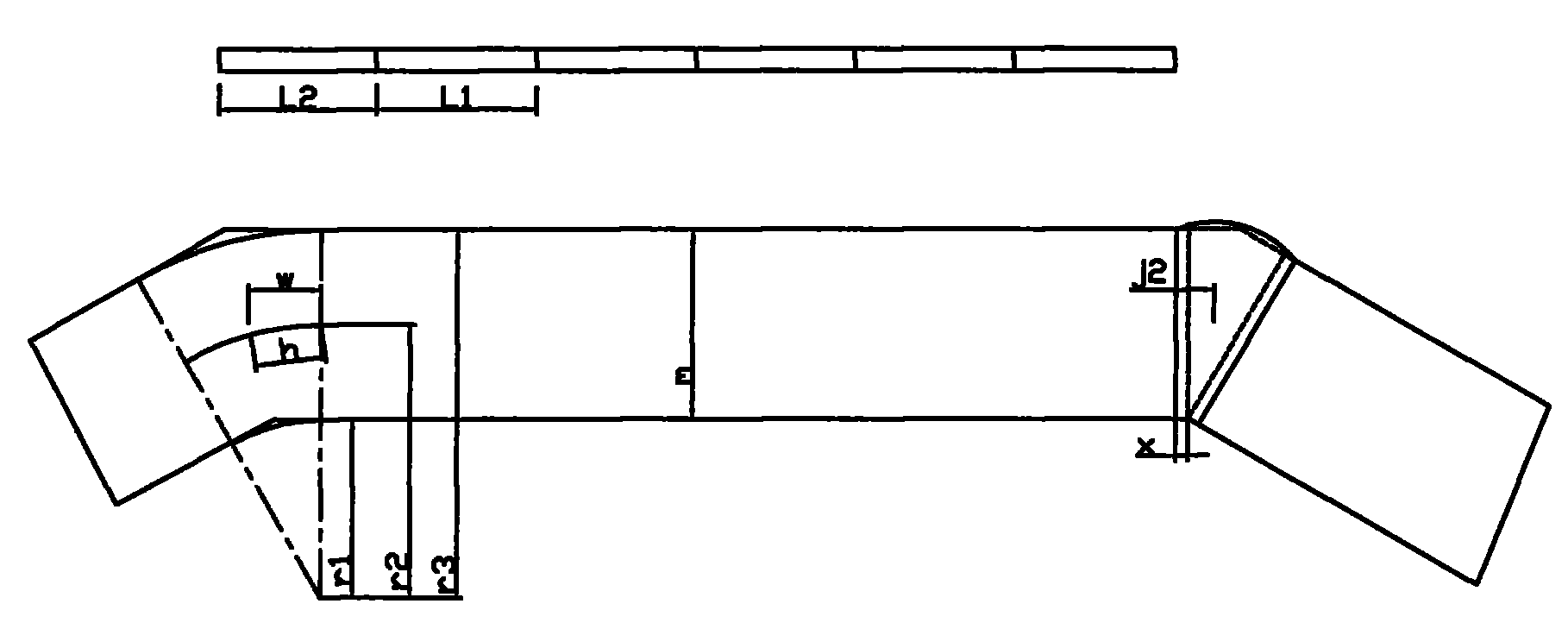

The invention relates to a manufacturing method of an intermateable plug-in type steel pipe pole tower, comprising the following steps: (1) calculation of plate width: according to the mouth breadth and thickness of steel pipes based on design specifications, single-side length of non-welded sides and welded sides and plate width when single-combining and double-combining are calculated; (2) discharging of steel plates: in the gun-releasing process of a discharging cutting nozzle, an operating table surface guarantees the planeness of a purchasing plate and a technique tip angle for tool-setting is formed when the steel plates are discharged; (3) the bending of the steel plates: operators are needed to adjust the central position of a pressing cutter to fall down to the center of a bendingedge; and (4) seam jointing: the process of combining and assembly before two bent steel plates being moulded into steel pipes comprises the steps: (4.1) control of diameter of a pipe port and roundness of the pipe port; (4.2) control of torsion of the bending edge; and in seam jointing, a jack and a draw hook tool are used for carrying out alignment correction on misaligned edges. The inventioncan realize batch intermateable, and reduces construction strength and construction convenience.

Description

A method of manufacturing an interfitting plug-in steel pipe tower technical field The invention relates to a manufacturing method of a plug-in steel pipe tower. Background technique With the rapid development of the power industry, the scale of investment in power infrastructure has been increasing in recent years. The plug-in (socket) steel pipe pole has the characteristics of simple structure, beautiful appearance, small foundation area, and convenient construction. It has been more and more used in the construction of power lines, especially in urban power line towers. pole tower. At present, domestic power line steel pipe towers mainly adopt two connection methods, namely flange connection type and plug-in (sleeve) connection type. The flange connection type has relatively complicated processing procedures due to the existence of flange connection nodes, and its appearance is not as good as plug-in (sleeve) connection. ) connected steel pipe poles are beautiful, so ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21C37/06B21D5/00B21D39/00B21C51/00

Inventor 王淑红戴刚平吕闪闪钱聪谷立坤舒芳史强

Owner ZHEJIANG SHENGDA STEEL TOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com