Desalting and deslagging device for supercritical water treatment of waste organic substances

A supercritical water and organic matter technology, which is applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. Can not be carried out normally, etc., to achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

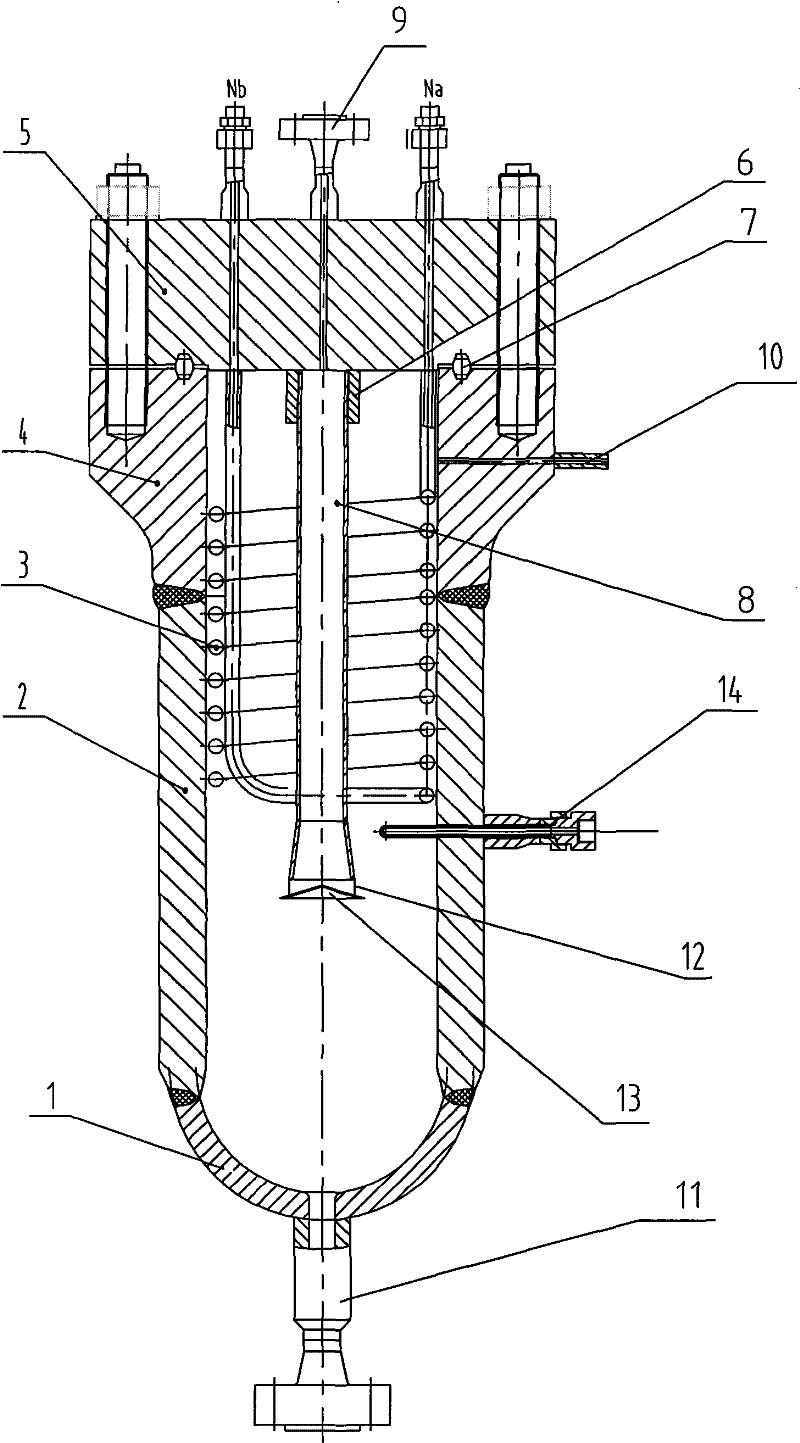

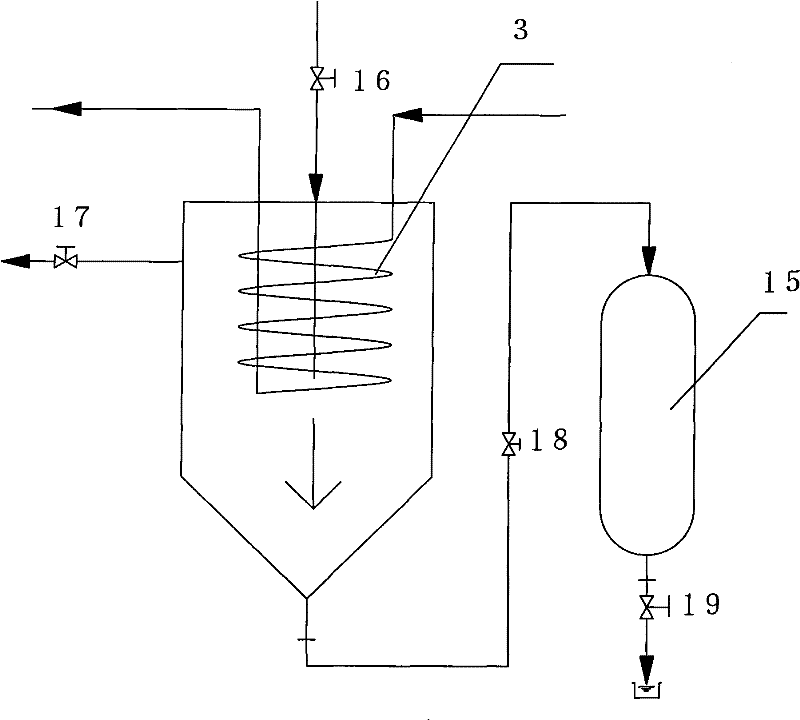

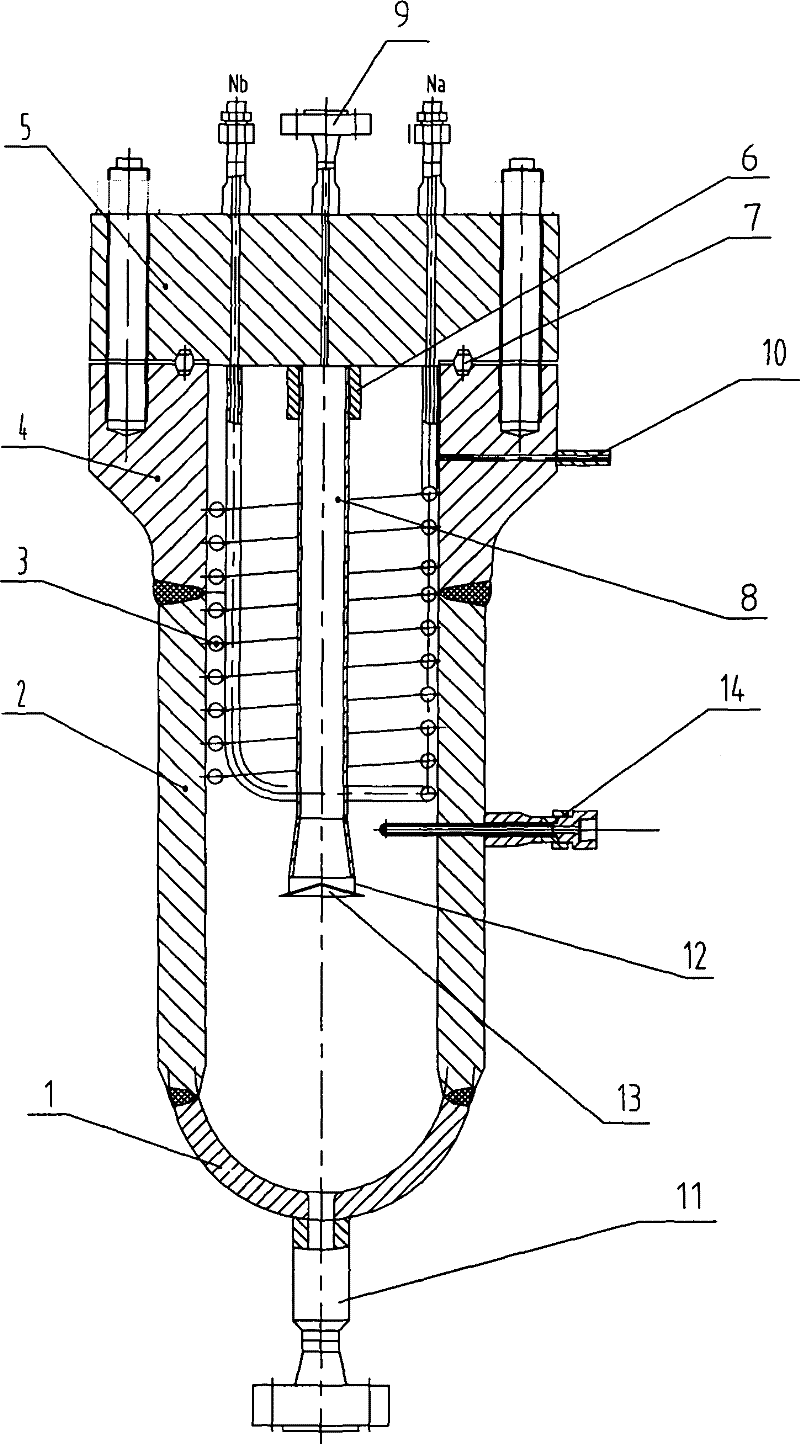

[0026] refer to figure 1 , the desalination and slag removal device for supercritical water treatment of waste organic matter, mainly includes: a cylinder body composed of a straight cylinder part 2 and an upper end part 4, an outlet pipe 10 arranged on the side wall of the upper end part 4 of the cylinder body, welded and fixed on the cylinder body The spherical head 1 at the lower end, the salt discharge pipe 11 arranged at the bottom of the spherical head 1, the end cap 5 fixed on the upper end 2 of the cylinder body by bolts, the heat exchange coil 3 arranged in the cylinder body, is arranged in the cylinder body and The central conduit 8 fixed on the bottom surface of the end cover 5 passes through the end cover 5 and communicates with the water inlet pipe 9 of the central conduit 8 .

[0027] The heat exchange coil 3 is spirally coiled, and its inlet and outlet respectively pass through the end cover 5 and extend out of the cylinder, and the heat exchange coil 3 is fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com