Octagonal automatic briquette press

A compacting machine and octagonal bead technology, applied in glass manufacturing equipment, glass forming, glass production and other directions, can solve problems such as low production efficiency, achieve the effect of easy perforation and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment this patent is described in further detail:

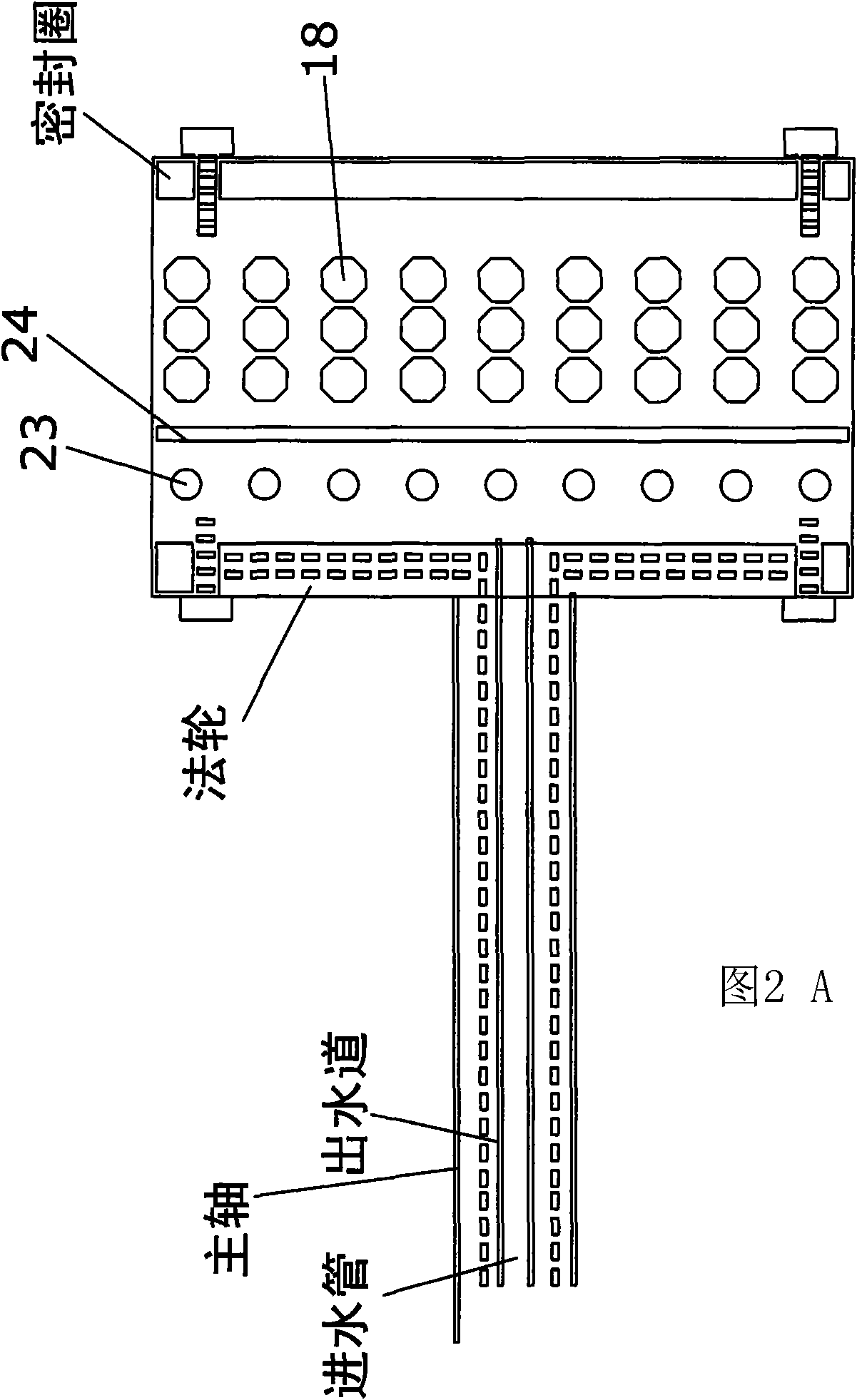

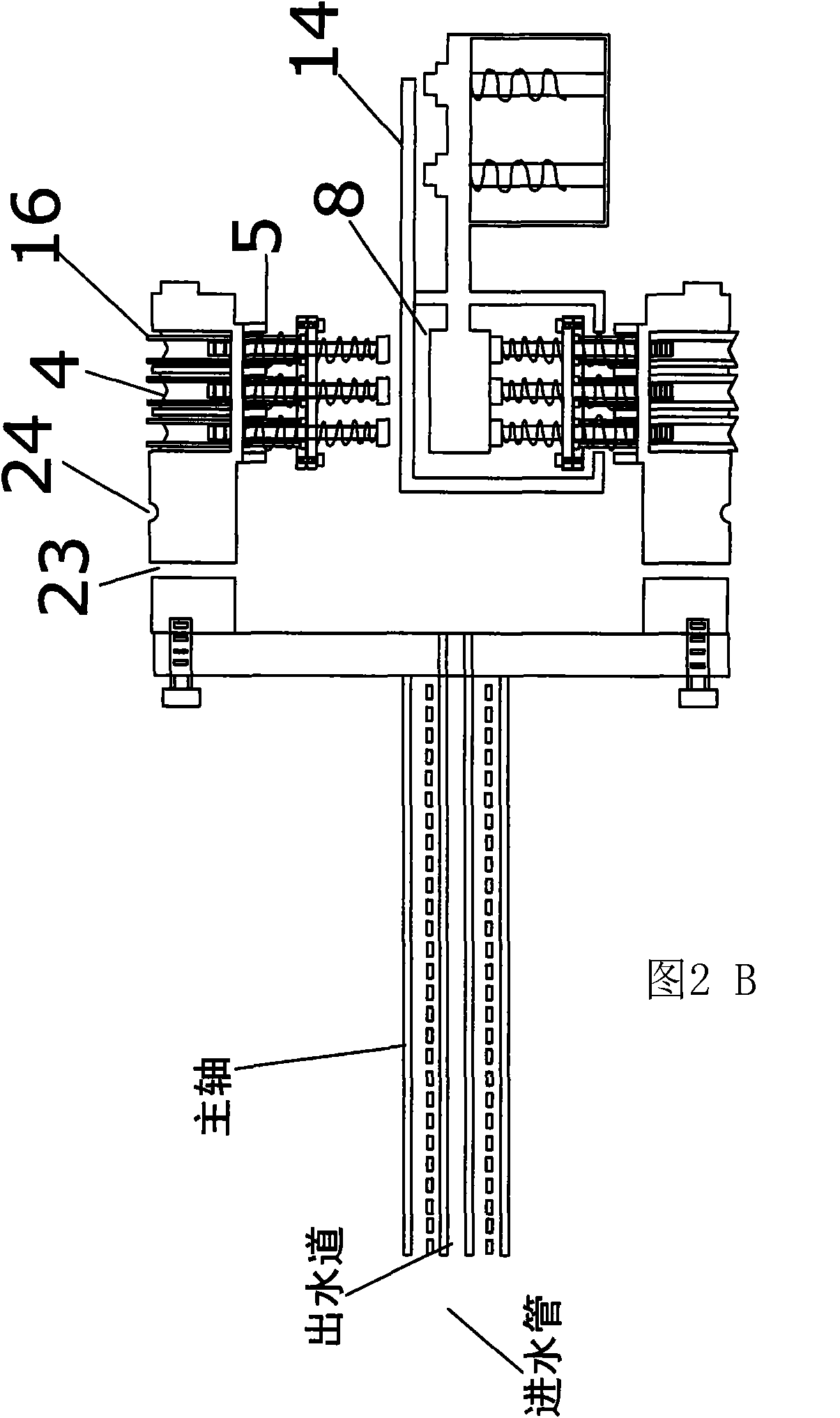

[0015] A kind of automatic billet pressing machine among the present embodiment takes making molded product---octagonal bead as example, as Figure 4 , Figure 5 shown.

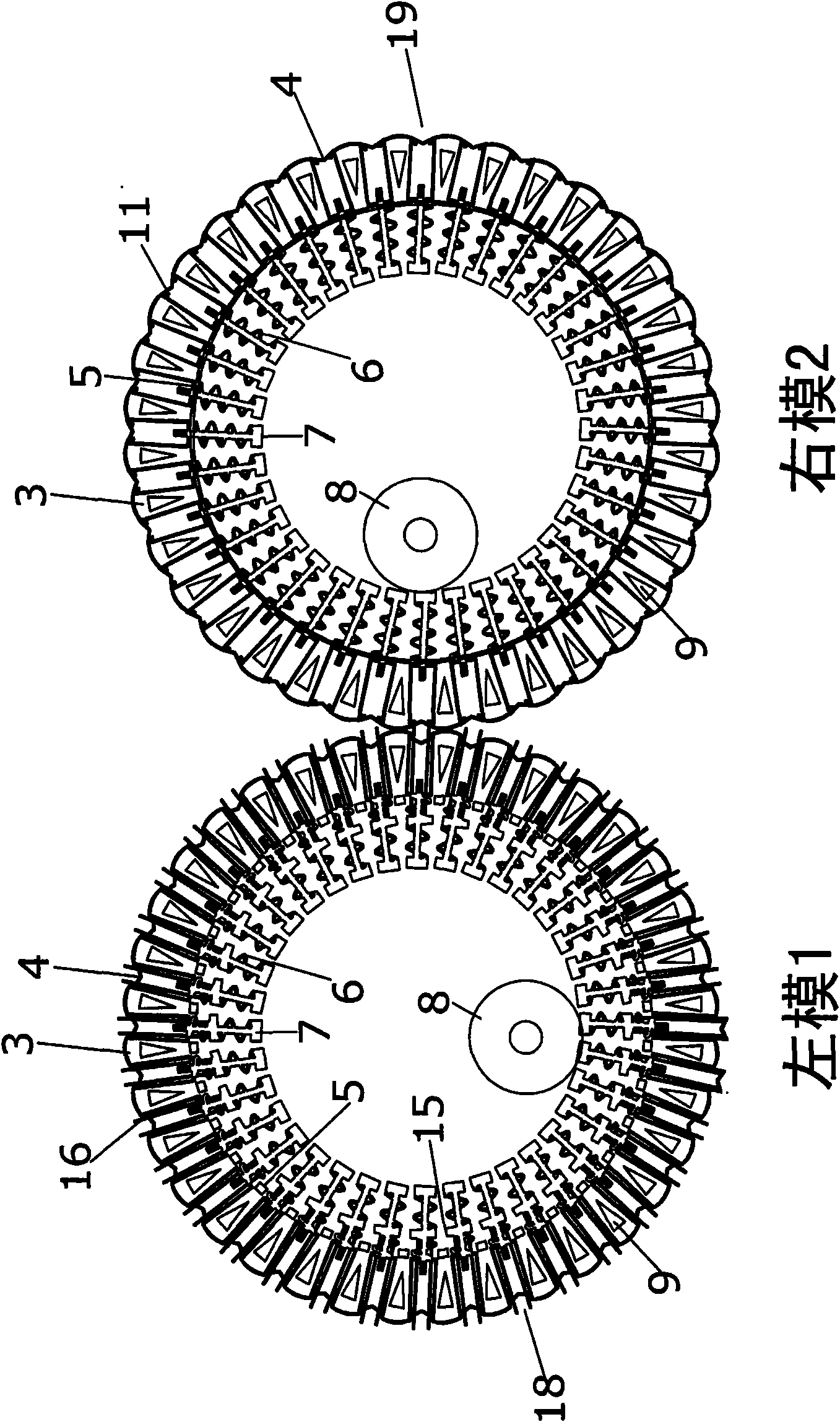

[0016] An octagonal bead automatic compacting machine comprises a frame, on which a power control device, a left mold 1, a right mold 2 and a fixed shaft are arranged, the main shaft of the left mold is driven by the power device, and the main shaft of the left and right molds is fixedly mounted on the main shaft. There are high-precision gears with the same size as the mold to make the left and right roll relatively. The left mold 1 rotates clockwise and controls the right mold 2 to rotate counterclockwise. The left mold 1 and the right mold 2 are circumscribed, and the cavities 18 of the left mold correspond to the cavities 19 of the right mold.

[0017] The edges of left mold 1 and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap